Leaderboard

Popular Content

Showing content with the highest reputation on 11/27/20 in all areas

-

18 points

-

High build primer is like sanding chalk! Coming out ok but taking a lot of sanding!16 points

-

Back to the story at hand - with the motor now ported, it left me with quite a dilemma. I bought this car with a specific budget to get it all done and dusted. I procrastinated for a few months while figuring out the next step. I even debated using the stock twins and the existing bolt on stuff, but deep down I knew that the stock turbos would just end up hurting the motor. One of my other good friends is a bit of a encyclopedia for turbo knowledge so I turned to him for advice. I was after something that could flow 400-450hp without giving away too much response. The ideal turbo would have been the Borg Warner EFR8374, but I couldn't afford a $4500 turbo. So the next best option was this guy: A Borg Warner S300SX-E, sorta the poor man's EFR8374. I chose a slighter smaller than usual 1.0 AR twin scroll turbine housing in an attempt to keep the boost threshold at a reasonable point, at the expense of some top end power. Given the most powerful car I've owned before was a 220kw turbo 4age, giving away some horsepower wasn't a real concern! I made another trip up to Auckland to dress the block up and install the motor - the turbo looks fucking huge compared to a bare bones 13B! And pretty snug in an FD engine bay too Because pedantry, I replaced most of the bolts on the motor, and engine bay, with shiny new gold passivated ones. I also splashed out and bought new coolant and washer fluid bottles, as the ones in the engine bay were all fucky. I also made the unusual (apparently) call to retain the stock OMP. Everybody says they fail yada yada yada, but I've not seen any concrete evidence that the electronic ones do. And also modern ECU tech can control them, so why the hell not? Modern ECU tech also means I ditched the Power FC once again, but this time replacing it with a Link G4 plug in It also meant a decent fuel system upgrade in the form of 1050cc primary injectors and 1550cc secondaries fed by one of the other wonders of modern tech, a brushless drop in fuel pump, capable of suppling well over 500hp worth of fuel. Thank god the days of Whinebro pumps are over! With this in the hole, only minor fabrication was needed to get it ready to fire up!7 points

-

This morning after dropping out the minuscule fuel tank I temporarily refitted the front suspension and pushed the Thames out into the sunlight. It's the first time it's left the shed in about 6 months. I couldn't resist taking a few snaps of it in daylight. It's sitting pretty high with all of the weight removed. It's going to stay outside until I've cleaned up the underside. Tomorrow I'll crack into it with some degreaser and my pressure cleaner.5 points

-

Progress - Had to get a few more Racepak cables in, sorted now. Engine running (!!!) with default tune, electronic dash and PDM operational, found baffle in muffler is loose so needs to be replaced, no major issues identified with plumbing. Waiting on fuel and oil pressure sensors and terminating CAN resistor. All default car functions hooked up to PDM. Still to do Air con wiring. Considering swapping out to AIM dash which is more street oriented with built in LEDs for all street functions. Will see, that dash looks a bit more modern than the IQ3.4 points

-

Heads all back on, timing done, exhaust back on, wiring underway. Been tweaking some bits in the bay, re routing wiring to hide it below the manifold etc. Starting to tidy up really nice, waiting for distributor to come back then I'll mount the carbs permanently. Hopefully at the tuner early December.4 points

-

Well that sucked. The forks started bottoming out a little on small bumps, then they stayed down and the front went light, front wheel washed out doing bang on 50k as it's a moped and it can't exceed 50k... Huge thanks to @Tumeke for pulling the bike off me, my leg was tangled in the kickstart. Also massive thanks to @johnnyfive for the punishing CT loaner!3 points

-

3 points

-

Welded on an exhaust hanger tonight and did a bolt check, everything's buttoned up and ready for wof re check tomorrow. See what wof man says.. turns out those red springs are lowering springs.. and completely slammed the crown. Juuuust under 100mm to cross member3 points

-

2 points

-

Did it. Much serenity was had and now she doesn't hate me as much for selling the spa pool to buy the boat. Swapped in another ignition control module and drained a good 100ml of water out of the filter. Will see on the next test run if the hot start issue is still there. I thought it was gone, but the second VG got in the boat - it did it again.2 points

-

Also, I managed to find the JDM factory service manuals for these, (not the USDM ones). They're in japanese, but can still be handy. Hit me up on a message / faeboes if you want em :-).2 points

-

Epic to see you've got yourself another one of these, looks like you're well down the rabbit hole with it! With the way prices have gone though, its easier to justify the outlay, hah. On the list of cars I regret selling, EEM46 is at the top of the list, but at the time I was working away from home and it was just sitting, somewhat brokenly in the garage, never getting touched. HPA are doing epic things with it, and they're promised to let me drive it when I'm down there doing work for them :-). I've seen the graphs from its new setup, makes a solid 400hp to the rears on the stock port motor (they havent opened it), and has boost in by 3000, so has pretty epic response too. The quote I have on it is that it is 'fast as fuck' :-). I'll always have the memories of dailying it to Waiau and back and hacking it around the track up there. Back before kids when I could afford a $300 a week fuel bill, lol ;-).2 points

-

2 points

-

2 points

-

Great news today. Had the compliance guy inspect the car from top to bottom. He was happy with everything and said go ahead and seal it up and paint it. He wants to see it all back together for the next check and then the last one is taking it for test drives and brake checks. So I was pretty stoked with that.2 points

-

I had a close call the other day! A rather high truck popped its tow ball bang into the center of my tail light, no panel damage thankfully. They agreed to sort it out and paid for a set of brand new rear lenses to be shipped over. In the mean time I had 1 old L/R lens on the shelf so I could keep on driving. We've managed to put 8,000km on the old girl in the 6 months she's been back on the road! Up and down the South Island with no problems so far. I've probably been a bit hard on it in my excitement because the clutch is feeling like it may need replacing soon, might pay to bed the next one in properly first... I still want to lower it some time, but the current height is pretty handy with how many gravel roads I find myself on. Perhaps air bags are in it's future? We'll see, for now it's too much fun to drive to put it back in the garage.2 points

-

2 points

-

so i bought a new (for me ..actually the newest car I've ever owned ) daily driver.(had it since august now) its a 2003 mk1 ford focus st170. i have wanted one of these for a long time and we didnt get many at all here in nz so they dont come up for sale ...very often .. they are problematic and are known to had issues from the day they came off the production line. but that problematic nature got me a good deal..it was $6900 from the dealer and had been traded in..(177000 odd ks.......should have imploded by now)..but evertime time someone test drove it the check engine light came on ..so they returned it...i drove it 3 times over the space of a week and the light came on within the test drive each time. (5min -30min). so i went back and just said i would take it off they're hands for $3500 with no warranty ....just slap a wof and reg on it and ill take it...(dont think they did much reading up on it.) few days later and probably a few other test drives they rang me and i went and picked it up...(engine light came on on the way home.) but as im pretty updo date on these things i also know that nothing the engine light comes on for will put it into limp mode....and some have had the light on for 10 years in the uk lol....they even say you should be concerned if it doesn't come on.... so a small run down on these mk1 focus st170. the motor is a 2.0 zetec (not duratec as it says on plug cover).the motor was developed by cosworth and is 2.0 block with forged pistons and a 10.2 compression. . alloy high flow head (the flow is shit to be honest and people have had huge gains porting them) , vvt on the intake (problematic) dual stage intake manifold (the controller is problematic ) stainless 4 into 2 into1 headers and high flow cat..and a sports exhaust ( sounds good) ..has a pre and post cat o2 seonsors (also problematic ).has a factory cold air feed to air box that doesnt acutallu go to the airbox. a dual mass flywheel 9 that i cant stand)and all of this is good for 170hp and the cut is 8000rpm. has a close ratio 6 speed box , quick rack steering , huge brakes front and rear , factory 17s with 215 tyres, traction control , factory reacrao seats , . and being a jap inport it doesnt have the uk rust ( and these things are dropping down in numbers daily due to the rust issues.)...its a blood fun car and handles well......even cocks a leg when you throw it into roundabouts.. since i had it ive had the inlet runner controler apart and cleared that code...replaced the pre o2 and cleared that code....(engine light came back on the same day lol). replaced the plugs (not cheap and need to be gapped at 1mm no more and no less...runs like shit otherwise)...i do have a new coil pack and leads on the way as well... i pulled the inlet manifold off last weekend (complete arse of a job) re greased the moving parts and changed the broken vacume hoses ..made a cold air feed and thats where im upto now.... i do have some plans for it slowly as it is my daily (seems better on 100 octane as well)..and just fix things as they go wrong......... and here she it......in imperial blue as well......mmmmmmmmmmmmmmmmm imperial blue1 point

-

Today I completed round one of cleaning of the underside. Used about a dozen cans of degreaser followed by a good water blast. Below are some pics that I took before I started. Most of the underside was pretty dry with some areas of sheet metal showing a light dusting of surface rust. The underside of the plywood floor in the load area looks to be in pretty good condition with just a thick smear of gunge above the gearbox tail shaft and another above the diff pinion. The side walls of the engine box were also pretty oily as were the areas around the brake and clutch pedal pivots which I guess is as a result of over greasing somewhere along the line. It doesn't look too bad after the first round, but the smears on the plywood floor are still noticeable, so I'll give those areas another go tomorrow. Thanks for looking.1 point

-

1 point

-

Can you bring this to Molesworth please Dave. I wanna ride CTs together with you1 point

-

Dunno about anyone else, but your pics are all working again now. Think it was just iforce being iforce haha1 point

-

Also, @Thphantum has obtained some food for roadside eatin' tomorrow (Friday), and @MaxPower is willing to cook a tub of something on Saturday night. Just an FYI, I wouldn't rely purely on these meals, but its might mean a bit less to carry all weekend. Many thanks to these two for their help.1 point

-

Indeed they do, and sometimes shit hits the fan and they ship the motors anyway... For anyone buying a fresh crate motor, you should pull down and inspect prior to installation. Separately, they aren't balanced all that well from factory. So if you're upping the boost or revs, best to get the rotating assembly balanced.1 point

-

1 point

-

1 point

-

Yea I am not sure it was an intelligent thing to do, but fuck I enjoyed the process, and it is a pleasure to actually get to use it. Seeing people's reactions to it so far has been great too.1 point

-

I like the fact that you could not find the right vehicle to suit your needs so you just made one. Good work!1 point

-

So both Jon and I are rotary guys from way back - we met back in the 90s while both driving FCs, and hung out in Paraparaumu. People from the region will know of the reputation it had for breeding some rowdy, rough, rugged and the occasional pretty quick rotary. Legend has it the very first rotor DX came from there! Naturally because of this, Jon wanted to build a bridgeport motor for this car. I wasn't super into the idea, as to do a bridgeport justice, it'd need way more serious gear than the car came with. Plus they aren't the most user friendly things for low speed, around town, general cruising, and I really just wanted something pretty quick but still usable. The stuff the car came with would easily support 220kw, which is heaps for a road car in reality. So I put the kaibosh on the idea. Stock ports are fine for what I want!. I get a message from Jon a few days later "Hey, it looks like they must test run these crate motors" Ahhh, why do you say that??? 'There's a bit of rust in the cooling jacket..." Oh FFS, I guess this is happening then. I got many pic updates over the following days as he quite gleefully hacked into my BRAND FUCKING NEW irons Now the first issue that I'd need to tackle anyway, was a decent clutch, because even a mild tune REW would torch a standard clutch without much hassle. No worries says Jon, I've got the old clutch from my Skyline, it'll be perfect for this. An OS Giken TS2B twin plate, with the necessary pull/push converter. Had done sub 1500km before he did a big upgrade, so ideal, albeit overkill for what I wanted. While it was in bits, I figured that I might as well get it all balanced, just for peace of mind. So the whole rotating assembly was sent off, returned all matchy matchy, and duly assembled.1 point

-

So obviously the motor was pretty much junk - the eccentric shaft was about the only usable part. This wasn't too much of a problem, as the car was comparatively cheap, and I'd bought it expecting to rebuild the motor anyway. We priced up all the parts, and it was going to be about 6k to do it correctly. I mulled on it for a while, and decided for not much more money, a crate motor would be a far better option. All new plates, all new housings, as well as all the little fiddly bits and pieces that come with the crate motor just made it a much much better option for longevity. After all, I just wanted a nice fun weekend toy that I could cruise around in! Also while the motor was out, I decided to fly up to Auckland and give the engine bay a quick respray, as it was in fairly awful condition. Rotaries and their under bonnet temps tend to melt paint off, and obviously this thing had seen some time at race tracks! So for a real quick and dirty spray job, it actually came up really nice. And this is where things started to spiral out of control...1 point

-

Had a pretty bit scare and save with the Datsun a few months back, went for an extended cruise up to Arthur's Pass and had some weird handling issues, incredibly unpredictable bump steer which felt like a gust of wind picking the car up. even getting out multiple times didn't show anything wrong. The following weekend with the car on stands it was obvious, the inner control arm nut had fallen off, the only thing holding the bush/arm in place was the steering knuckle (which obscured it from view on the roadside) all time holy fuck, bullet dodged kinda moment! Searching through my collection of odds and ends I found a new nyloc but the washer has a tab to prevent spinning, quick CAD and sent to the waterjet This has left me wondering if the mystery wobble i've been chasing is related, I can confirm the handling has been far better since. With the car on form, we loaded up the convoy and headed to Datsun Nats in Cromwell, not many pics cos driving, but a bloody good weekend! Tomorrow's rust, today! Did get a few laps around Highlands, quality teaser to wish I had the money to do it in anger.1 point

-

I pulled the lower arms out of this today and what a crumbly mess I found. Luckily last time I had it in bits I cleaned all the threads and greased the torsion bar hexes so it came to bits nicely today. after a little grinding and a nudge in the press, good as new, Thanks to Valiant Precision Driving Team captain @cletus for supplying some new rubber bushes. The old bus should regain its razor sharp handling characteristics.1 point

-

1 point

-

1 point

-

As the budget also wouldn't allow for new housings and rotors, I picked up a secondhand matching rotor, and a secondhand housing. Haynes Rotary were doing housing resurfacing at the time, and I figured for a couple of hundred, it was worth investing in the process. Both housings came back looking absolutely stunning Then I went to Custom Works (I'd left there by this stage, divorce etc took its toll on me) and got Hayden to help me assemble the block after hours Reassembling all the ancilliaries was fun, snapped the OMP lines so had to spend more money I didn't have to put it all back together. With all the shit bolted on, you couldn't even see the damn things!1 point

-

Oh hai. Figured after the better part of a decade I'd update this. In the end, I chose to rebuild the existing engine. Even though I knew I'd probably have to sell the car anyway, my ego wouldn't let me halfass the car like every typical rotor dickhead back then. Especially as it was so goddamn tidy. I dropped a bunch of money at my local friendly Mazda dealership (Jim @ Capital City is the man) and bought all new seals, springs and a full ($$) engine gasket set. The only components I didn't replace were the oil control rings as they were in OK condition, and at a couple of hundred each (x4) it was beyond the budget. Spent a fun couple of evenings cleaning and clearancing each rotor1 point

-

Toshihiko at TKRJ pistons got back to me informing me that they don't have stock of the 1.75 or 2.00 over options, but they have the 1.50 I've already got available. Ended up asking him for exact measurements of the piston, they are between 48.450 to 48.470. My current 1.50 measured up at 48.305 and the cylinder at 48.495. Worst case fitment is 48.495 - 48.450 = 0.045 clearance in the cylinder! So it would actually need a slight hone to fit!! Also if I ever order another Chinese/Taiwanese kit I'm granting permission for everyone to give me an ass kicking!1 point

-

1 point

-

Soooo, I kinda fucked my knee, as in big time fucked it. No, I wasn't riding a dirt bike, a harley, scooter, motorized mobility scooter, tall bike, drift trike, gokart...nope, not even a goped. I simply went to step up onto a deck and some shit broke inside my knee. Totally unspectacular, no cool "war stories" to tell... Now my biggest problem i was about to face is that I drink coffee like water. In fact some days I don't drink water other than what comes in my coffee or beer. So I was getting kind of desperate to solve this first world problem...but never fear, a solution was in hand, introducing the copyright pending "crup holder":1 point

-

These are 'feet' for the sump. So the engine can stand upright. Good chance ill break them off at some point so I printed a hole up them and bonded in some steel dowels. Started bogging.1 point

-

Fitting up well. Inserts and removable pieces are looking good. Its going to take a bit of bog before paint and a lot of sanding afterwards.1 point

-

1 point

-

1 point

-

Did bit of a time laps video of the camtree casting. Not great but its a start.1 point

-

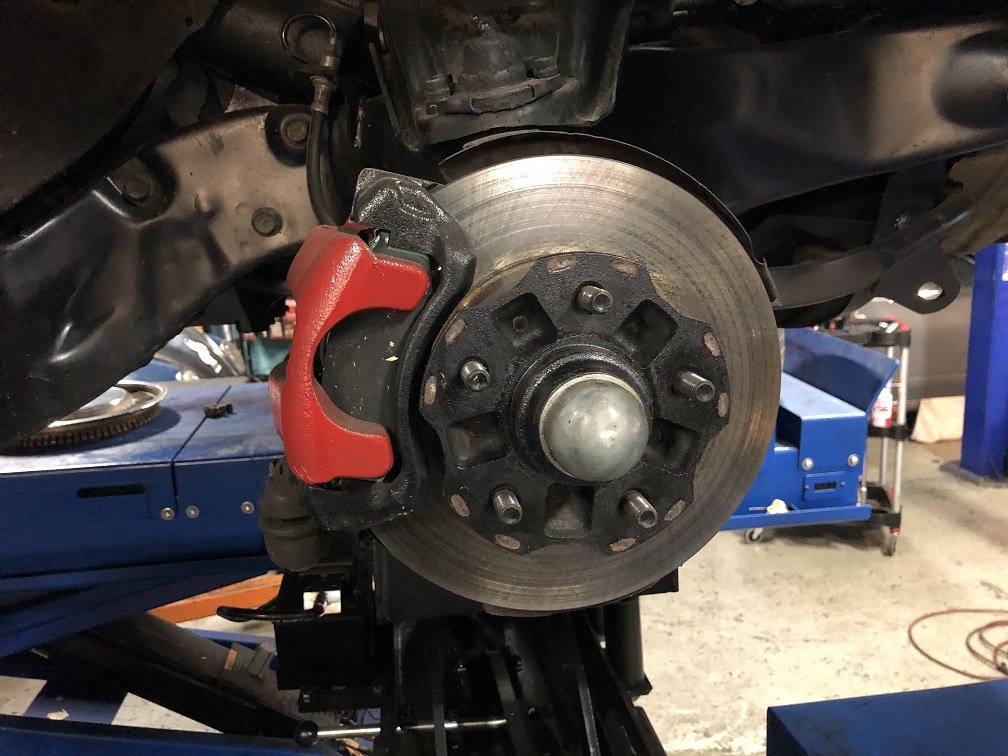

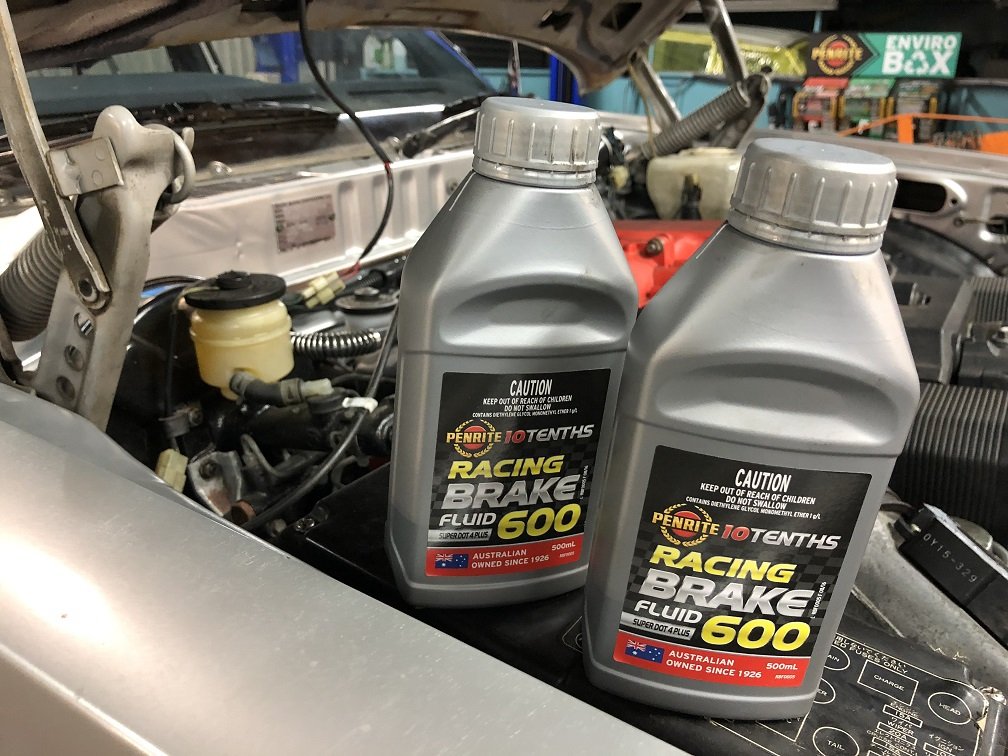

So I swapped out the ancient genuine Toyota pads that obviously weren't up to the job with some Ferodo's and also changed the brake fluid to something a bit overkill. The brakes were completely different after that, so much better. They were able to bring the old boat to a stand still from 100kph in under 4 seconds consistently, and cert man was happy. I've been filling time waiting for the plate by making up new brackets to fit my old Cressida visor and throwing on some clip on white walls for the complete sleeper look! Hopefully the cert plate will arrive any day now and then I'll be hitting the road for some quality road trips!1 point

-

Wagon is on its way home today. Really happy to have it all done and dusted and then it will head off to the Cert guy in a few weeks. Towers are a bit bigger then i had expected given the suspension isnt too big1 point

-

Went down and checked out the progress last week and was happy with how everything is going. Have spoken to Andy Smith the cert guy and he is happy with the current progress. Car will head up to Levin in the coming weeks to get his approval. Top of the strut towers were to be made out of 5mm steel and the rest was made of 3mm thick steel as per the request of the Certifier. a tad over kill possibly but better to be safe. The adjustables come really close to top suspension arm but i will replace them with aftermarket adjustable arms Back of the strut towers were made flat and clear the rear seat which is good1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpg.a5b052eadcb502338fa7a85b8de95cda.jpg)

.thumb.jpg.b947e8574e71878b2baeea5b08d17e4f.jpg)