Leaderboard

Popular Content

Showing content with the highest reputation on 09/26/20 in Posts

-

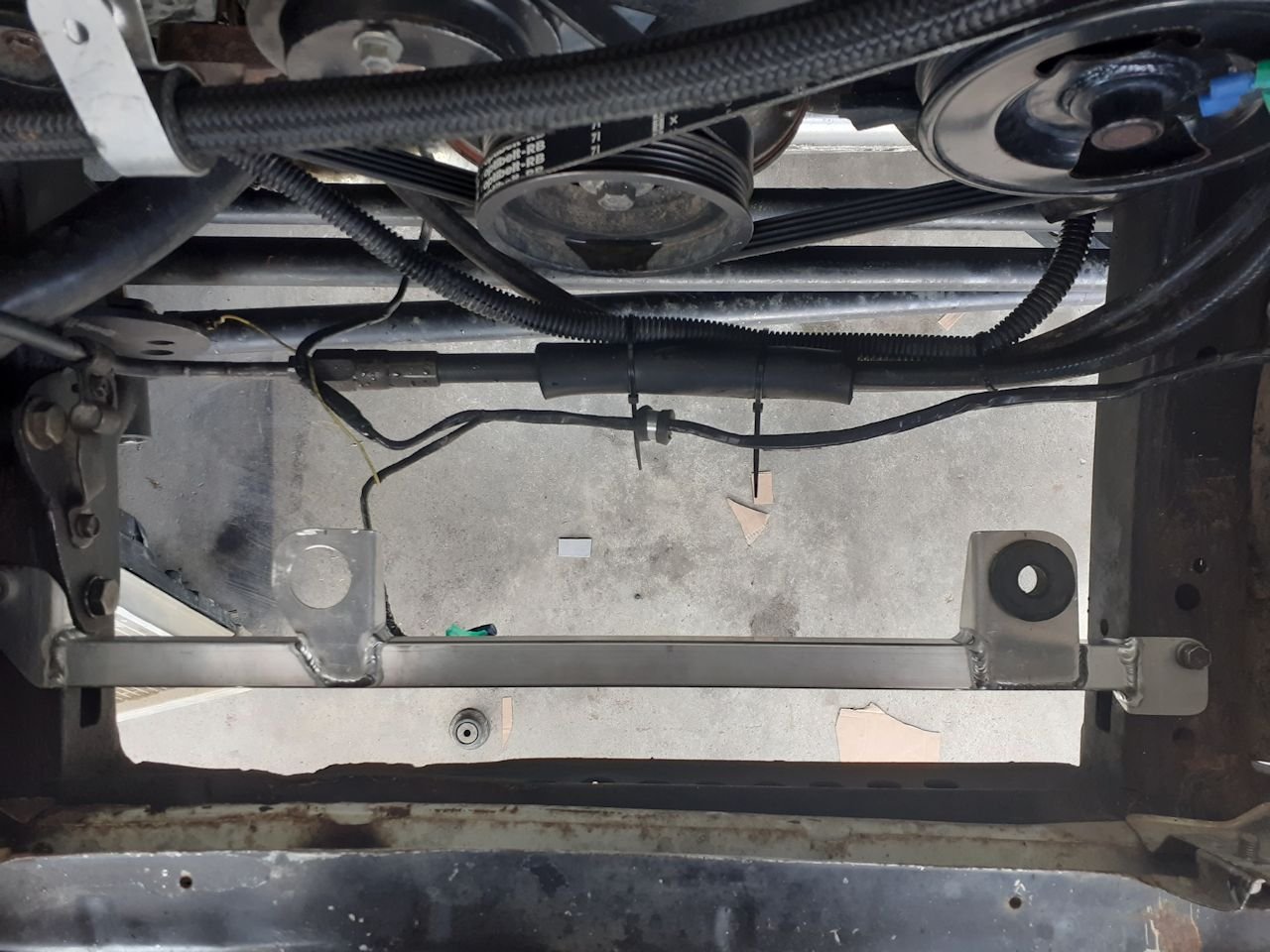

Picked up from autoblast this morning and dropped off for engine bay paint. Looks ok apart from they painted the black parts underneath then primed the engine bay so theres primer overspray on the inner guards and in the tunnel. Which is a bummer as that was the whole reason for taking it to them because I wanted it done nicely. I mentioned it and the guy came out with a rattlecan of black paint and some rubberised underseal to throw on before the towie arrived, which I didnt want on it I didn't want to leave it there for them to fix cause I'd already had to postpone the towie and the booking at the panel shop a week, because it wasn't ready last weekend as per the booking I made 6 weeks ago. So I'll get the painter to fix it, should just need a quick blow over with some more black after hes done the green parts And the hoodlining is ripped for some reason now. Bah. Anyway, I pulled the sump off to change the oil pump and pickup back to a stock one instead of a high volume pump. Its had a couple of times in the past where it lost pressure after a prolonged period of high rpm. I was concerned it was emptying the sump faster than it could drain back, and someone i talked to about it said that on a SB mopar, a stock pickup with a high volume pump can cause cavitation issues. Someone else said a high volume pump is unnecessary anyway as once it gets to x amount of pressure the relief valve bypasses so then the oil just gets whizzed around the pump doing nothing I'll try a stock pump and see how it goes, and also add some baffles, I got a new pan cause the old one has had a few bumps and an oil drain on the wrong side now I got brave and popped a couple of bearing caps off and they looked fine17 points

-

15 points

-

As some might have seen in my wanted advert I've been looking for a Nissan k11 Micra (march) for a while, mainly to have as a daily for when the Imp eventually goes under the knife to get its new flat six heart, but also just because both Hannah and I fancy k11s. There's a bit of history with them for us both and this connection along with just the cute unpretentious little car looks has us hooked. Not to mention that overseas there are some wickedly cool uprated versions doing the rounds. Quite a following for these cars in many countries except weirdly in NZ. When I was living in the UK I'd spot these everywhere. Very popular little cars, but ones that I looked past. That is until Hannah's younger sister needed to buy her first car. I helped them look for one and a Micra K10 came up for sale locally. We knew little about them except that Hannah and her two other sisters both learned to drive in K10s. Simple,easy cars to operate (685kg light too!!) So we Leila bought the little K10 and loved her first car, which became known as the Badger mobile - due to the trips Leila would take in it to Badgermans beach down in Cornwall... Sadly, because mother nature can throw out some right horrid things at us, Leila became ill with a rare disease called Crest syndrome, a type of auto immune thing. It started with her hands and she was unable to operate some items, including the windows. The little K10 became a bit run down and the road salt had done its job. Combined with the trickyness of using cars controls Leila decided to seek out a more suitable car. This is where the little K11 came to reside with Hannahs family. Hannah helped her look for a suitable car and then her brother found one. A four door 1000 facelift in dark blue. It had electric windows and central locking- two small things that made life for Leila show much easier... That little K11 did many missions about the place and the family became quite fond of it. Its also what made me start spotting K11s and becoming a fan. In a horrible turn of events Leilas life was cut short. The condition had continued to worsen to the point where it was effecting her heart. She died from a heart attack in 2017 at only 26. A huge loss to the world. Her little Micra was then taken on by Hannahs brother and he now continues to take it on adventures and the other siblings borrow it. I used last year for the 2019 Retro rides gathering - this being the first time I had ever driven a Micra any real distance and I really enjoyed it. While at the gathering I also spotted and fell in love with this little hillclimb beasty... I was amazed at how peppy it was for a 1000cc car. Its handling was 'floaty' but fun. I could instantly see how they would make a sweet little pocket rocket for twisty roads- in very much the same way as the Imp is. Hannah was also smitten and of course there is the family connection to add. So we would own a K11 one day- that was that! Fast forward to last month. I old my Viva wagon during lockdown and had some cash. I know that the Imp is to come off the road for the transplant. Lets start looking for a K11. There were requirements to be met though. It has to be a manual, two door, pre-facelift (PFL) and ideally would have the CG13 engine- not the smaller 1.0. But we soon found that these combined features are a very rare thing indeed in NZ. Kiwis never got Micras here new. They are all imports from Japan. Most are auto (CVT) with the 1.0 and most are 4 doors. All the earlier pre-facelift models, made up to the change over point of around 97, seem to have disappeared. Weirdly - Australia had them new - imported from the UK! They apparently are all PFLs too! Lucky. We found a very tidy 2 door manual face lift locally- but it stunk of ciggy smoke, was a 1.0 and a couple of other alarm bells rang about the owners and their honesty. They were also asking moon beams for it and wouldn't accept my lower offer. Plus- it was a not so pretty facelift version... Then this 4 door PFL turned up locally, going cheap. After a quick look up on carjam we found out that it was a 1.3! Also spotted in the photos were a rev counter. That rev counter dash is certainly a rare thing here- quite a bonus. With some more research Hannah deduced that it might be a March S. These have a few extras like the rev counter and a split rear seat. I messaged the seller and he confirmed it had the split rear seat. Oooooh we thought! Now a March S is not the same as a Micra Super S- as sold in the UK and Oz. I believe that the Super S has a few other blingy things like rear disc brakes, sportier seats, quicker steering rack and a deep front spoiler with added fog lights. ^Dreams. We went for a look. First thing I checked was the engine number- just making sure it was indeed a 1.3 with all those extra 20 ponies. Took it for a hoon (wow- the 1.3 is way faster ! ) checked some things and made a cheeky low offer. 2 days later there was a counter offer and we bagged it for a nice cheap enough price of $825 Picked it up yesterday afternoon. Bought some engine flush, oil, filter and new plugs. Will giive it a bit of Tlc. Its a bit dented and rough but will still clean up ok. Plans : 1 - look for a tidy 2 door PFL car to swap all the good bits into. Probably will be an auto 1.0. Wont be a quick job this so it can wait till later in summer because there are way more urgent jobs about the place. Plus this car is meant to be a runner to use while the Imp is off the road- not another project..... but hey. How can we not have a play! 2 - Lower it. Most likely using some garden variety 'Makita modified' springs... Apparently one can remove 2 coils and they will remain safely contained. We shall see. 3 - Find some nice alloy wheels. 13" x 6 would be nice. The pcd is 100mm so not too odd. 4 - Hannah wants a yellow Micra. So eventually it will be re-painted the official Nissan custard yellow.. 5 - add a turbo. Maybe. Could be fun. That's a way off in jobs to do here though! So here are some pics I took... The seller had the most amazing jumper on! I'd have been stoked if that came with the car... Before handing over the monies I thought it best to quickly check that the spark plugs were not seized in the head. Not coomon but worth checking to save a lot of aggro... All good! So we paid the man and hooned off into the sunset- me in the Imp and Hannah getting used to 'her' new toy Filled the tank.. Played cat and mouse over our hill to home... I took some quick pics in the evening light... JDM factory crystal for added healing power and bling. Some Marches came with these factory fitted... One key element to a good Micra... Another great thing to have when you're ragging all those little ponies to the point of exhaustion... \ Some service items... More to come soon. Lets see how much money we find under the seats etc14 points

-

Made a small thermette for my sister's birthday.12 points

-

Awesome day! Thanks to everyone involved with organising it. Glad I wore all the gear today and survived my first lowside.... in the middle of nowhere, but directly in front of a a marae where 3 people happened to be working on the grounds! Pretty funny to fall off and hear “YOU ALL GOOD BRO?” from up the hill.10 points

-

10 points

-

Fluids and filters changed, tank of gas, air in the tyres and off it went for a warrant. I was expecting there to be at least a few minor bugs. But nope. I'm all legal and good to go.9 points

-

I think the standard heads and even the stock manifold can flow quite well. Plus they apparently handle a bit of boost on the stock bottom end ok (if sensible) So this morning I swapped the plugs out. The old ones are certainly old with eroded rounded electrodes but clean- no signs of an oil burner and a nice light brown colour... We took it out for hard trash around 'the loop'.. a good drive if its quiet and no freedom campers sitting on 30kph. Up and down, narrow windy road with a decent hillclimb to finish on before home. Perfect for little cars with big hearts. It pretty fun. Almost forget its just a little 1300 until you hit 6500 and then select third and it falls on its face. Luckily it seems fine with staying in 2nd all the time for the really tight bits. I think the few cars we saw heading the other way must have thought 'wtf! Well look at that Karen- I think those kids are on meth and have just stolen some grannies car for a joy ride' We got some dirty looks Got home and poured some engine flush into the engine and ran it for ten minutes at idle. Never used this stuff before but thought why not- oil on dip stick looked/smelt fairly dirty. Hannah then did an oil and filter change. We'd have used the hoist but someone has thoughtfully filled the floor up with loads of timber for some glorified shelf build. Poo. Sump plug and draining easy to do on the ground. Oil filter not so easy - not when the last monkey had overtightened it. But all good and sorted. Old oil yuck. New oil yum. Engine even sounds a bit quieter. Thought I would check the air filter. Hmmmm. There is no air filter installed! FFS. Luckily there is a fine stainless mesh covering the TB mouth. So a filter is on the list before we next drive it. No wonder the engine sounds so neat. Also- both cv boots are torn so that's another job- especially before we start Colin Mcraeing it on the gravel roads.8 points

-

6 points

-

6 points

-

6 points

-

6 points

-

5 points

-

4 points

-

Top marks on getting a CG13 one....did a bit of looking ages ago, they go quite easily into a mini.3 points

-

3 points

-

3 points

-

2 points

-

Have been chipping away slowly. Torqued all the the bolts on the front strut's up to cert specs. Then had to pull both struts apart as a ~0.5mm spacer wasn't needed. I had previously found it was needed as one pad didn't fit. This time I found it wasn't needed... so hopefully a drive around the block will sort the slight rub of one pad. Without the spacer plate, the pads have a gap sub 1mm, with one slightly touching, still easy enough to spin so I think that will sort itself after a drive. Installed the diff back into the car, nightmare one man job. Took a lot of pissing around as some of the arms are super tight. Got there in the end. I stripped the surface rust off all the arms and gave them a couple of coats of paint. No pics of this as I spent too long cursing and losing the will to live. Bolted an adjustable MRP panhard rod in for the first time, shocks bolted up. Still need to work out what i'll do for bump stops, not being able to chop some down is a bit of a ball ache. Have left handbrake cables flapping in the wind for now as I need to bleed the brakes first. Drums were completely rebuilt, so that side of things is done. Hoping to get the brakes up and working this week, then I can get it off the axle stands it's been on for months and get it outside. Boring update, but just trying to keep the momentum going. I've also installed the dash back into the car and hopefully plugged everything back in correctly. Brakes together for hopefully final time Heater ducting, couldn't find a duct in the parts pile for this section so made one up with some 75mm flexipipe stuff. Had to flatten it below the emissions ECU as it's a tight fit between that and the glovebox. Hub installed with bolts for brake upgrade kit. Ticked and torque written down so I know it's done. And wheel arch repair. Was the only part that needed replacing, due to a prang which caused it to rust out. The rest of the arch has some surface rust so I gave it a really good clean up and sanded off what I could. Then put some Brunox over it. Will epoxy prime the inside too so that any moisture can't get to the area. It was either that or replace the whole rear arch for the sake of some very light rust between the skins. A: that's above my paygrade B: seems a bit extreme as it won't get any worse. The repair I did took an hour to weld as it's so thin I could only do a couple of spot welds at a time, while letting it cool again. Relatively boring update done, if you made it this far, you've done well.2 points

-

2 points

-

2 points

-

1 point

-

Any airbag related wiring should have a yellow plug. If that black plug is the only wiring going into the seat, unplug it and see if the airbag light comes on. If not, rip that shit out, no problem.1 point

-

1 point

-

Sumps all gooed up and torqued back on fuck I hope it doesnt leak. Did a bolt check of the motor and decided to paint the front bits of the alternator I've marked a reference point in the electric choke housing and rotated it 2 clicks clockwise and see how it goes once I fire it up. Before I put the motor back I'm going to check and make sure all the lights/indicators are still working/replace bulbs, general bolt check all round and put motor back in tomorrow/Sunday Gasket goo says wait 24 hours so I'd better wait that Atleast. I dont want to pull it back out again.1 point

-

1 point

-

More wire stuff. So to make an omelette first you must break some eggs. So trials first, glad I did. I have just about completed the first section of the engine wiring. Feeling pumped. Also picked up some weld on AN fittings and top radiator return block from Taarks for the cooling system. More on this later.1 point

-

This is about as flat as we got it. Got all the flakey bits off however the height difference between the metal and the paint surface was still quite uneven, quite a few microns. There's no typical auto paint that could look good on that surface - However, the coating system I had in mind was thicker than the micron difference and stuck like high school nick name. I just hope it would work as I hadn't seen it applied to such a rugged surface. Here's a pic of it prepped and waterproofed. We took it camping like this looking all ratty, was crack up watching all the people looking at it in disgust when it arrived at the campground but a few came by to say they thought the opening back end was pretty cool. I was tempted to leave it like this but also wanted to ensure it was waterproof so ended up painting it.1 point

-

I’ve now made the move to Palmy and have spent this week sorting out the wee workshop I’m renting. I’ve set up a bunch of shelves, built a bench and added a tyre rack along the back. It’s about 40m2 (10m deep, 4m wide) and has a decent high stud so I can hang junk from the ceiling if needed. The unit number will make @kpr jealous: #unit4A Unwrapped my fresh bottom end for the first time... really keen to get the head built now... Then I finished the rear suspension guff from the previous post, removed the springs and dropped it on the ground to see what rubs. The front LCA angles are pretty bad at this height. This is on bumps and I don’t have roll centre adjusters yet. At full compression the front lower arms just touch the chassis and the tyres rub on part of the inner guard (I’ll remedy this before finishing the engine bay tidy up). The lowest point of the chassis rails are are at 35mm or so. That’s with 225/45/15 tyres... probably safe enough to not scrape ripple strips at full compression? It will never run this low, but it’s good to see what the suspension will do over big bumps.1 point

-

The new m/cyl looks great. Do me a favor and pull the mastervac check valve out, poke the longest finger (or didget!) you posses in there and let me know if there's any residual brake fluid there. if there is PM me and I'll talk you through a booster rebuild or you can bring it (and a bottle) to the world famous sr2 mancave in Milford and we'll do it in person.1 point

-

So, I've been busy with lots of little jobs during the reassembly. Refurbing badges and fitting them, along with a fair few NOS ones too Lots of NOS lenses and lights Had to make up seals for some of them I found a really good plastic restoration product for pieces like the louvers And fitted them up While de-orange peeling I managed to sand through the clearcoat on the passenger door, was fuming. So I had to repaint that. Then it was time to get everything running nicely again so I can get back to driving it! I've been starting the engine up pretty regularly, so it's still running quite well. However I was having a problem with the throttle sticking, which seemed to be caused by one of the carb mechanisms being quite gunked up. When I tried to clean it all up the bloody things fell off. Luckily I had these things lying around the garage and wouldn't you know it, they fit pretty well. So I got them on with the help of a mechanic friend and managed to learn enough about carbs to roughly tune them myself via YouTube tutorials. They sound awesome. Far from optimal but smooth enough to drive around the neighbourhood for the first time in a couple of years. Was feeling pretty fucking chuffed with myself, I don't mind telling you. So, WOF tomorrow, fix any issues that come up there, then a proper dyno tune. I'm interested to see how much difference there is compared to the factory set up. Then drive the shit out of it. Also need to clean it properly before I take some decent photos of the new paintjob in the sun…1 point

-

Well with being back in lockdown has provided some time (when I’m on my off shift) so I got the engine almost repainted and assembled new gaskets, frost plugs etc Hoist earning its keep again Messed around with a couple of ideas on the rocker covers settled on engine coloured with black fins Ended up with this, still have to do the other rocker cover to match, just waiting on some more paint, I ended up getting VHT early Chrysler blue, it’s a bit greener than I what I was planning on using, but I’m actually happy as with how it has come out! not a bad use of a day off1 point

-

1 point

-

1 point

-

1 point

-

So, this car needs a lot of wood. Henry Ford bought ~300,000 acres of timber land in the Upper Peninsula of Michigan and built a town, sawmill and hydro plant. The wood was used in Model T's and later Ford cars right up to the end of real Woodie production in 1951. Here's a history snippet: After WWII station wagon building resumed at Iron Mountain and all of the Ford and Mercury staAfter ttion wagons and Sportsmen convertibles were built here. The station wagons were four-door and lasted until the new 1949 model which was only available as a two-door. With the introduction of the "New Generation" Ford, the amount of timber used in the station wagons was cut around 85 percent. No structural wood was required as the wagon bodies were steel structured with mahogany-skinned panel work and maple framing. Mercury also used the same body for their wagon but the doors were cleverly restyled to flow into the wider front sheet metal of the Mercury. The new design was the work of E.T. "Bob" Gregorie and his team at Ford. The steel body structures were built in Detroit and then shipped by rail to Iron Mountain. Here the wood panels were installed and the bodies were painted. The work required a lot of hand assembly to make the doors and side panels fit cleanly. The panels for these New-Generation wagons were assembled using advanced fabrication methods with one of the first microwave curing processes. Some section framings were created out of six loose layers of ash with a two layer overlay of maple. The door and side panels were then formed in a press using loose wood-plys topped with a thin layer of Honduran mahogany. This jig-formed panel was then put into a micro-wave bonding oven under pressure. At the time, this process was referred to as "radio frequency bonding." The new process cured the panel in five minutes rather than the 48 hours it normally took! Once the bodies were completed they were shipped out by rail to assembly plants around the country. The final run of Ford's "wood" Station Wagons looked somewhat similar from 1949 to 1951; however, there were many small differences in the wagons. These were the years of the "single and twin-spinner" Fords and in 1950 there was an attempt to lower the production costs when Ford dropped the wood graining on the tailgate and replaced it with a painted tailgate. The rear quarter windows were eliminated, the interior trimming was changed, with wood-grained Masonite door panels and a painted dash board replacing the wood graining. Other running changes were made with some items re-introduced and then dropped again on the 1951 model. As so many minor changes were made to this series of station wagons, restorers have a hard time determining exactly what a correct year model should or should not have. Around October 1950, the mahogany paneling on the station wagons was replaced with Di-Noc plastic vinyl sheeting bonded to steel panels. Chrysler had been using this trimming idea on their Town and Countrys since 1948. Chrysler dropped Di-Noc and converted over to body color panels and wood framing in mid-1949. Ford continued building the Ford and Mercury station wagons at the Iron Mountain plant until December 1951, when the plant was closed and 3,500 workers were laid off. To take up the loss of production of Ford and Mercury station wagons, production was moved to Mitchell-Bentley in Ionia, Michigan. While in the USA for work last year (we won't be back there for a while I suppose) we visited Rick Mack. He's probably the best supplier of this type of wood. As noted above, the frames were laminated in the original ford design. This because there is a lot of curve in the pieces as the come up over the upper parts of the door 'skin'. If they were bandsawed out from a timber blank then the grain would weaken the structure. Rick doesn't use a microwave bonding but laminates the wood strips into forms using a press. Pic below is Rick's personal woodie. End result of the visit was an order for a full wood set. :1 point

-

1 point

-

Some handy hints from doing exhaust pipes 1. I always use cotton reel style mounts, and I mount them the wrong way so they are in tension. I've done a few this way and never had one fail, the ones in the VG have been there for 9 years now. I use 50mm diameter mounts with a 10mm thread. This makes it easy to remove the exhaust, and gives you some adjustability via packers if you need to 2. Cutting u bends can be a bit of a prick, my cut off saw cant do a nice cut on this size pipe, I use a big hose clamp around the pipe to mark a cut line 3. I use pot belly paint from bunnings to paint exhausts and it lasts better than hi temp stuff from a can1 point

-

I was going to keep this rear section for a 'one day' (/never) couch build but after advertising the seats on FB, @Cbomb came down and took most of the 4-door parts away. The rest of the shell went to scrap, although I heard later that some local whanau cherry picked some bits to be used in an art project of some sort. Also, the owner of the chassis needed some cash after buying too many motorcycles, so I ended up buying it so it's still sitting in the driveway. It's RHD, but might be useful for some parts or to use as a temporary body support (although I suspect the woodie chassis may be different in some way)1 point

-

I have had a VIN assigned for the woodie so it's properly recorded in LANDATA for the future. I also had the local Repair Certifier come down and take a look before I did anything. He confirmed that it's OK to go ahead and start work replacing the rot myself. He's since passed this project on to the new owner of the shop. so I'll have to get him down for a look sometime soon too. After that I felt it was OK to do a little dismantling. Removed the hood (floppy) and some of the grille bits and the drivers side guard for access to the A-pillar. Also had a go at replicating the front under-floor support. It was hard going in 16g, I made the sides separately using the nibble to fold the bend over as a flange then welding sections into the base. Turned out 'OK' but might end up making it again now I've had a practice run.1 point

-

1 point

-

1 point

-

1 point

-

After much mucking around looking at how and where to mount the power steer pump and then reading they aren't much good and then looking into fitting an electric ps pump instead but reading about how many ergs they need then I'd need an expensive alternator bla bla bla I decided fuck it and ordered a manual box instead. Rock auto is awesome. I ordered it on Saturday and it was here when I got home today. They are available in two different ratios so I got the quicker one Header flanges are cut so I can pick those up tomorrow And drop the trans off for rebuild on saturday . Progress1 point

-

Went to hamilton today to pick up this fine specimen. It's a 8.8 ford diff out of a 91-99 explorer. There are a few reasons for using this. They are cheap ish, have discs and a decent handbrake setup , lsd, 31 spline axles, same diff as a mustang so plenty of aftermarket parts available, and if you narrow one axle tube 3" and use 2 short axles it makes it just the right width and pinion offset for a valiant. I do have a 9" that I was going to use, but it has already been narrowed but not enough. New housing and axles was going to be 2k, plus rebuild the diff and get a lsd center, plus brake conversion, was probably the best part of 3.5- 4k. And yay, wheels fit over the brakes.1 point

-

1 point

This leaderboard is set to Auckland/GMT+12:00