Leaderboard

Popular Content

Showing content with the highest reputation on 02/21/20 in all areas

-

14 points

-

8 points

-

3 points

-

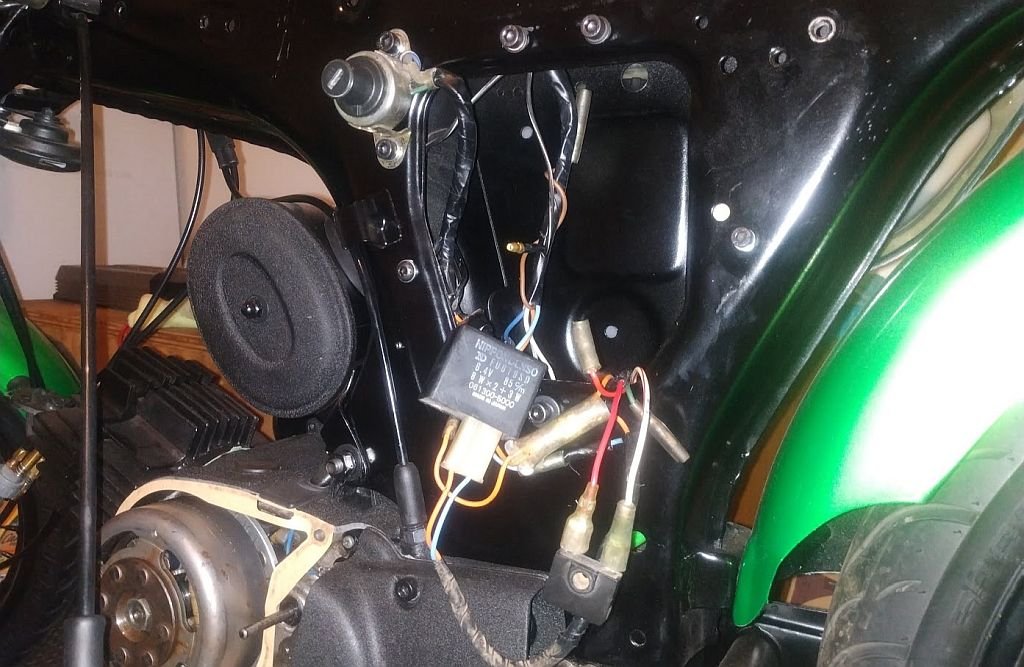

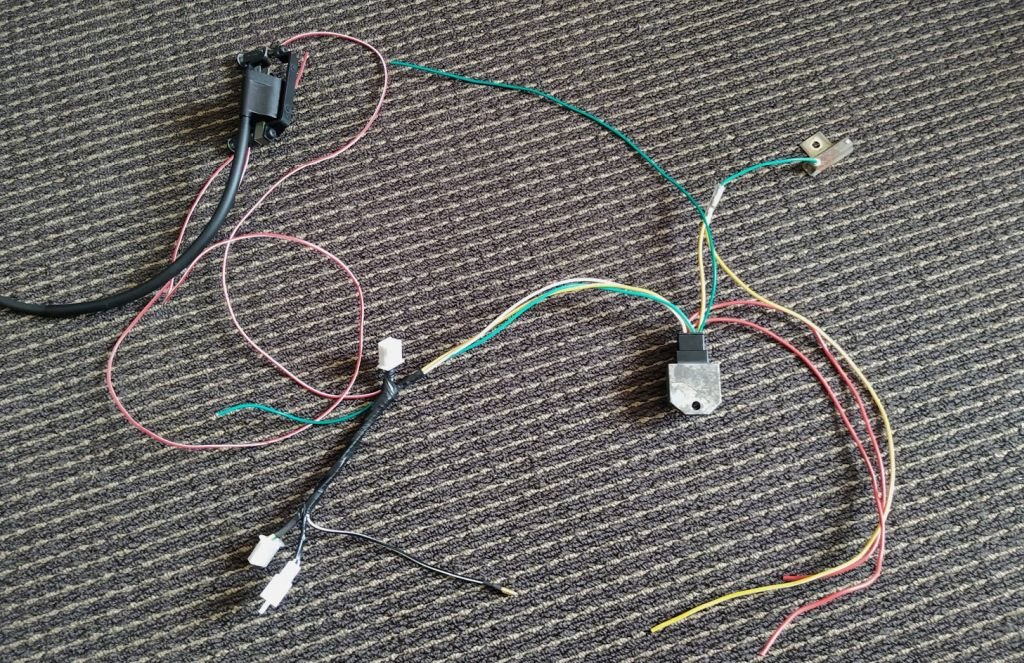

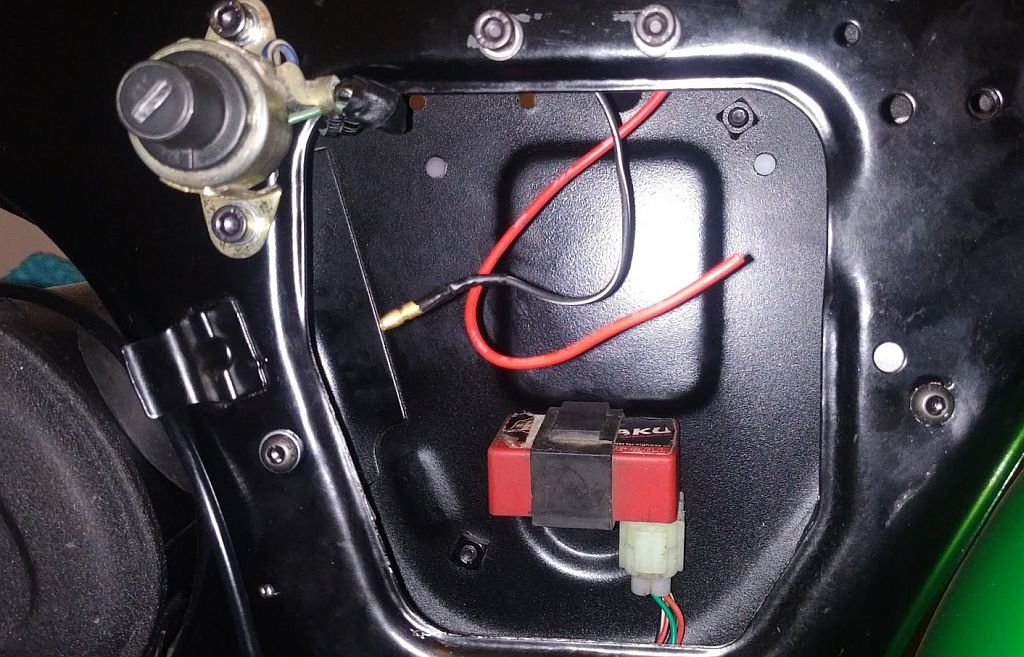

Factory wiring while functional was never too pretty So made up a small loom to patch the CDI, reg/rect, ballast resistor etc into the stock loom after a bit of thinning out Since the coil is hidden deep inside the frame I had zero fucks to give about looks when it came to the adapter for the new coil lol After a bit of mucking about making brackets, stripping out any wires I don't need anymore and rerouting things this is what I'm left with Planning on chucking a LiFoPo4 battery in the factory mount (not pictured) once @MopedNZ is back at work/I've got $$ to drop on a fancy battery. Then it was out with the old And in with the new Airbox is purely decorative now, need to turn it into a storage space I think So now it's "just" a case of getting the exhaust nut from Jonny, making an exhaust, painting a few bits, making a slightly longer choke cable and putting it back together!2 points

-

Well sadly at my last Akl OS meet my battery died (RIP mr NS60LMF, you gave all you had to give.... August 2011-Jan 2020...) thanks to @Thousand Dollar Supercar for the jump!2 points

-

2 points

-

Sorting out the wring from the alternator to the the original fuse box in the Holden and the second loom that controls the power train. I thought it was probably a good idea to put some sort of fusible link in reasonably close to the alternator, I'm worried about wiring getting cooked should it get too close to something very hot or a sharp edge. Would using an inline 80 or 100 Amp link for a high power stereo be OK. Some of these come in holders that would be really easy to mount and keep things tidy or is there a better way?1 point

-

1 point

-

See the first post in this thread for the location. The next meet will be the 18th of March, but I'll be in Wellington that week. It's probably for the best that the XJS has fallen out of favour.. Definitely don't watch the bidding on this auction to see how cheaply you could put yourself into a V12 coupe.1 point

-

Is it a discovery or defender? Manual or auto? Fit an egt and boost gauge and increase the fueling and boost and it will be a lot nicer to drive, the 300tdi is a great engine, good economy easy to work on and very reliable.1 point

-

1 point

-

Close. But the bigend journal size is too small. Also are they bearing type not split? The problem im finding is that generally the longer the rod is the bigger the journal size. So 7in rods have about 2in journal Theres a lot of American stuff thats close but would like to find something metric.1 point

-

The injector pump can draw from the tank but you will find it down on power a bit, mine was. New lift pump is cheap as and easy to fit1 point

-

If I use a piece of string and straight line it from the engine cog to the rear sprocket it’s off. Got a new swing arm on the way so I’ll fit that and see how it looks. If it’s all good I’ll strip the paint off it and hit it with the left over black 2k I painted the rest of the frame in.1 point

-

@d.p.n.s yeah im way too lazy when it comes to updating my threads! Just need to work out rod lengths and piston compression heights for the crank. Looking like VQ30DE pistons and RB30 or 8v FE SOHC rods for it to sit at zero deck with about 10:1 compression. Other hand is use 4.1 X-flow pistons and 4.0 EL rods for about 8:1. If i can get a combo to get 9.5:1 or 9:1 then ill be happy as that leaves it open for boost....1 point

-

1 point

-

I have a challenge for you guys. Im look for OEM parts to design around. Starting with Shell bearings and Con Rods. Bearings: Big End. 45mm Diameter. 35mm wide Mains. 60mm diameter 28mm wide Con Rod: 180mm long 45mm bearing (49mm? bearing dependent) 35mm wide Ive found Subi main bearings in the EG33 are 60mm diameter but they dont look wide enough. Old 911 looks close too. Same problem with the big end. Lots of 45mm diameter but not wide enough. The conrod length is super long. Ford Model T or Flathead are 7in which would be fine. But journal diameter is too big. Hoping you guys can help figure out a combo.1 point

-

1 point

-

1 point

-

I have finally managed to get most of the shaping/repairs done, a few wavy bits and a couple of dings here and there, sorted now. I was also having some problems with leftovers from the old respray reacting with the primer and wrinkling on the roof. I solved the problem by bare metalling the whole roof and starting again, to be sure there was nothing underneath. All good now. So now it's all painted up in filler primer, ready for blocking. It's looking quite good already, pretty crisp and straight. Bonnet and guards not attached properly here, which is why the alignment of the front end is all off. Not bad for a noob effort, I think. There's a tiny bit of fine tuning needed, shapewise, a couple of things which weren't easily visible until it was all light grey. But in general looking pretty good, will block it back and get it as straight as poss, then time for colour, at long last.1 point

-

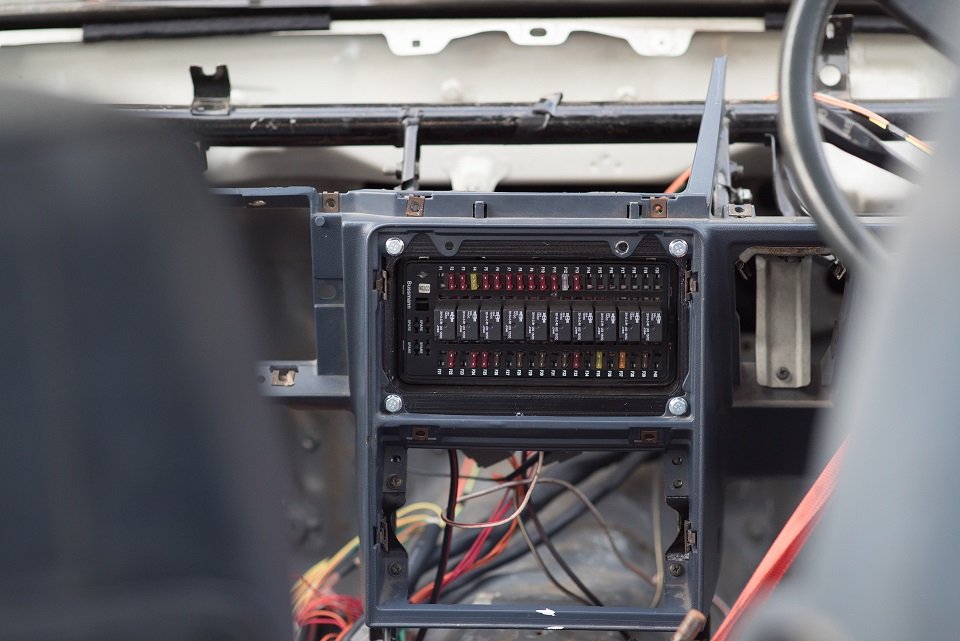

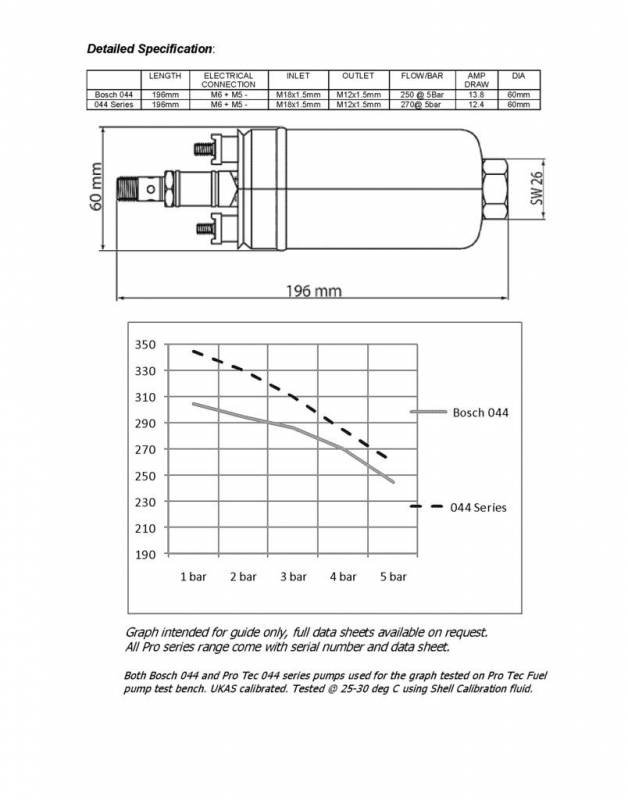

Fusebox all working. But not before I realized I'd wired 9 out of 10 relays backwards. Woops. Lucky was easy to fix. Also, I've always hated the idea of an external FPR, its just so big and shit looking compared to the OEM ones direct on the rail. Since I'm making an effort to keep things tidier though, and this will sneak in behind the cam cover and look discrete. Pinched from the Redtop engine's factory setup. Think I'll give it a hoon. Has the secondary benefit of that I can just run a smaller EFI spec rubber return line hose back to the firewall tucked under the inlet. Rather than a full sized AN-6 line from the rail to the FPR. These FPRs all only regulate to 300kpa (43psi) down from the 60psi I've been using. I havent managed to find a 60psi factory FPR, funnily enough because the only cars that run 60psi or higher are returnless systems. So let me tell you a punishing story about why that is. Traditionally, EFI systems have run at around 43psi. If you're wondering why the weird number, 43.5 psi is 300kpa, and no one in their right mind uses imperial units to design things. Anyway, this pressure range is a good trade off between how hard the pump has to work/reliability, how much fuel it can deliver, and good atomization. As you raise the fuel pressure the l/min rating of the pump decreases. So keeping the base pressure lower effectively gives you a higher flowing pump for same hardware = cheap. Look how much flow rate a Bosch 044 loses when pressure goes up. It also means that as you add boost, and the fuel pressure needs to go up to suit. Spec sheets for electric fuel pumps show that most start to creak and lose heaps of flow after 65psi or so, and with reduced lifespan. With 43psi base pressure and 20 pounds boost only means 63psi required at the pump. Which is considerably better than trying to achieve 80psi. So, why do modern cars run 60psi base fuel pressure instead? When emissions rules are really tight, Fuel vapour emissions are a big problem. When you heat up fuel at the fuel rail and send it back to the tank, it creates heaps of vapour. As well as that when you open the gas cap, this pressurized hot fuel vapour rushes out which is also an issue they need to minimize. A secondary problem here is that fuel isnt just made of 1 thing, it's made of lots of different chemicals which have different boiling points. My understanding is that the additives that turn 95 octane into 98 octane, are the first to flash off into vapour. So minimizing the fuel heating reduces your octane level loss over time. The fix for these problems is to make sure fuel that goes to the rail, never gets back to the tank. Hence returnless. But now the problem is that at 43psi, if it sits long enough in a hot fuel rail it reaches its boiling point. So 60+ psi raises the boiling point above where this is an issue. Which is also why they dont vacuum reference the FPR in the gask tank on returnless, because you never want to drop the fuel pressure below 60psi absolute. And a modern ECU can just deal with a varying differential fuel pressure a lot better than old shitters can. So in my case, going back to 43psi will be fine but with lower pressure the injector duty cycle will need to creep up a bit. As at 60psi Altezza injectors are 450cc/min Injector, at 43psi it's only 370cc. So I'll need 21% more injector opening time. Currently I only get to around 63% duty cycle at lots of RPM so that'll end up around 76% duty cycle instead. No drama. I will just need to be mindful of when controlling the fuel pump with PWM, that I'm not setting the flow rate too low that it'll have time to boil the fuel. Although these engines have a fairly well insulated fuel rail compared to some other engines where they are stuck in a valley or whatever. The other problem is that my fuel pressure sensor now has nowhere to go, as previously went into the FPR. I managed to find an AN fitting that has a pressure port on the side, so I'll mount this with the sensor whacked in somewhere after the fuel filter on the inlet hose when it turns up. I got the Bosch E-throttle all working nicely, it's very snappy testing via ECU. It looks like I'll need to ramp down the PID settings a bit compared to Altezza one. Will take some 100hz logs and try fine tune it. Speaking of which, this PID tuning explanation is bloody amazing So now I've gotta sort an E-throttle pedal. I've got two options so far to try, but isnt looking as easy as I'd hoped. First is RX-8 pedal, on the left. Convenient option but it doesnt really fit nicely in the available space. The other issue is that the APS sensors are built into the entire pedal assembly. So if it shits itself, you have to rebuy the whole thing which seems stupid. The other option I've been looking at is a 350Z APS sensor, which looks like a normal TPS but has a little bar on it to be moved by a pedal somehow. This doesnt particularly look like it wants to cooperate with the factory pedal, so need to figure out something else there as well. However it does make it a lot easier to keep a spare and replace if it packs up. But I like the idea of keeping the factory pedal, so if I end up using a cable again to test something I've still got the option. Although I guess I could just refit the factory pedal anyway in that case haha.1 point

-

Improvements made to bracket. Looked "a little heavy" for my liking...so off to Jenny Craig's she goes! Nice hole, with a cheeky peek up her skirt. Rounded all the corners with a generous radius. Ready for paint now. Much happier with its appearance. If something is ugly, it's best to not draw attention towards it, so by doing these extra steps hopefully it'll become less visible and go unnoticed.1 point

-

so yea, it goes. had to push the throttle by hand because i haven't got the e throttle working yet. pretty stoked tbh, it goes fucking mint. if i can figure out the e throttle setup i might be able to drive it tomorrow. sorry the video is a bit shit, i was trying to doort and film at the same time.1 point

-

I put this outrigger on. I think for certification I need to guard the belt drive? Then, I rolled it outside and it stood for the first time in its life on it's own. As a father of 3, I can say that this emotional experience far eclipsed watching my own kids takes their first steps. So close, yet so far away for starting it up.1 point

-

1 point

-

1 point

-

1 point

-

Took radiator to be flow checked and it's fine. Looks good inside where you can see, no corrosion or whatever. Cut the tanks and made it a triple pass. Still temp climbs. Not as fast as before but it's still climbing. Tested both thermostats to make sure they open about where they say they will and also to make sure the bypass blocking plate on the back of the thermostat reaches the hole it's supposed to block. One was better then the other so I put that in. It's still getting hot, just does it a bit slower now.0 points

This leaderboard is set to Auckland/GMT+12:00

_sedan_(23230030334)(1).thumb.jpg.34d765361d66c78db614bae6ea2c156a.jpg)

.jpeg.7dbde483b963e88ca5bb2c4549d1ecec.jpeg)