Leaderboard

Popular Content

Showing content with the highest reputation on 11/12/19 in all areas

-

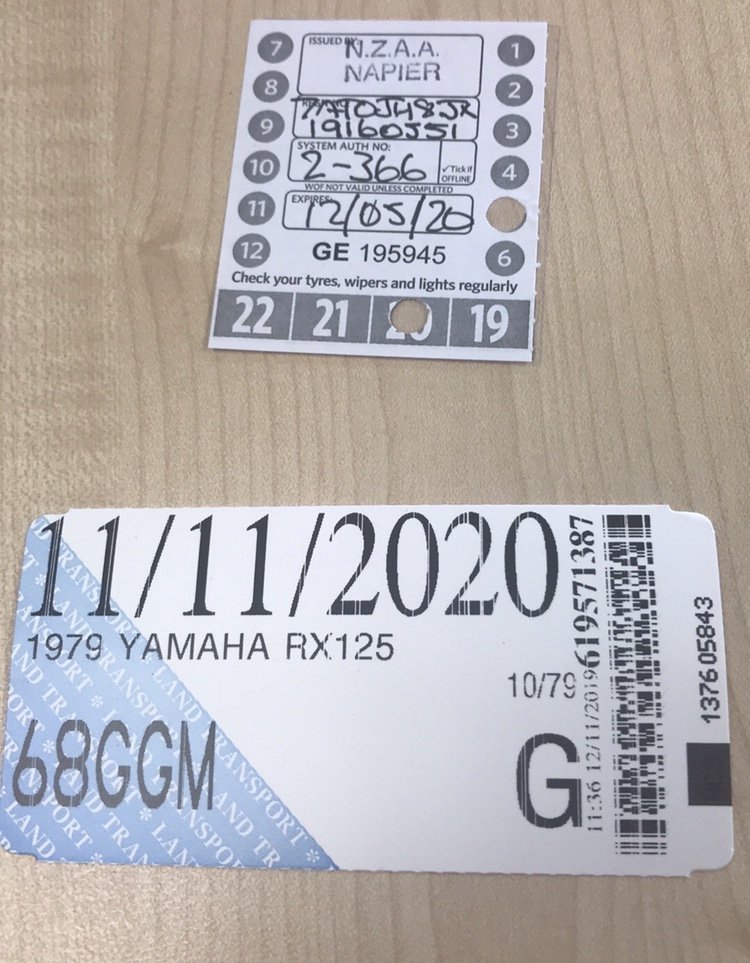

Hello all. I now have some first hand experience in re-registering a motorcycle that has previously been registered in New Zealand. so I thought I would re-cap the process for those interested. Note: may vary for cars. the motorcycle in question is a 1979 Yamaha RX125. This particular bike had not been registered since 1986 and was not recorded in the NZTA data. The only proof of previous registration was it’s original plate and attached wof tag. a few months back I walked into the AA testing station in Napier and asked for everything I needed before taking it in. The helpful gentleman told me I required two things; proof of ownership and proof of previous registration in New Zealand. He stated as the bike was pre 1990 I did not require a brake declaration. for proof of ownership, AA provided me with a standard statutory declaration form which I filled out and had declared and signed by a notary public at the Napier District Court. This took all of two minutes to obtain. for proof of previous registration all I had was the wof tag and number plate which the inspector accepted. i rung them up yesterday morning and booked the bike in for the following day (today). Dropped bike off at 8am and by 11:30 they text to say it was finished. When I got there the inspector asked me to show all the lights and indicators etc worked. Then they ran it through what I assumed to be a standard wof check which it passed with no issues. the cost was $180 then registration for 12 months on top of that. they even re-used my original plate, even without having to get the authority myself from that lady at NZTA which was great. all in all a very easy process and the guys at AA Napier were extremely helpful and efficient. hope this helps for anyone who wanted up to date knowledge on how the process works.14 points

-

10 points

-

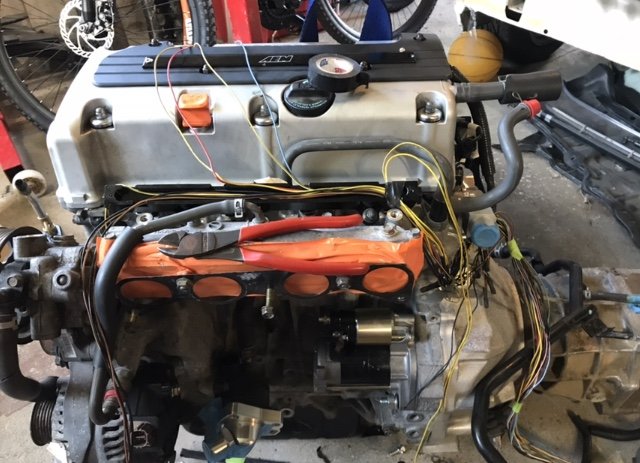

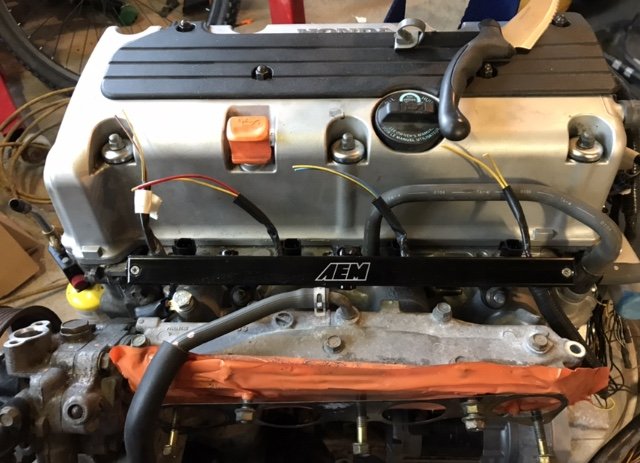

Been a while since and update, headers turned up, pretty happy with them considering how cheap they were to buy and ship to NZ, started and finished de-burring the valley (what a crap job to do) next up was to clean it all down to get rid of and filings from the de-burr and to get rid of any solvents/etc from the machine shop, picked up a bottle brush for getting into all the little holes etc and grabbed a tube of engine assembly lube, Found a perfect use for the shower in the garage then started to assemble the bottom end, fitted new Clevite crank bearings fitted the new rear main seal and crank, put new Sealed power big end bearings in the old ones had seen better days, then fitted new Mahle piston rings and dropped the pistons back in, All in all a productive night after training on Wednesday I should get the cam in and timed up. Then I can slap the rest of it together, also I still have under seal to scrape, but I’m being a slacker and have left it for a while8 points

-

Aaaaand she’s legal as a drug sniffing beagle! i described my revin process in the revin thread, but today I got this thing back on the road. Stoked as fuck. even get to keep the original plate! 68 Gag em since last update I decided I thought I’d bang some off road-ish tyres on it considering my main premise for this bike is light off road duties. I managed to track down a PPSC control tyre Shinko SR241 in 2.75 x 18 for the front and a Shinko SR244 in 3.00 x 18 for the rear. The front needed a bit of a massage and some self clearancing to fit, but the rear fits comfortably. well what now!?!! I need to get the seat recovered and paint those side covers in original silver. Decided I’m gonna keep the OG silver tank and it’s patina, and get some decals done. then perhaps make some tasteful scrambler mods.... Bring on the Te Urewera Undertaking!!!7 points

-

Yup, much the same as last year, we racing for slips this time?6 points

-

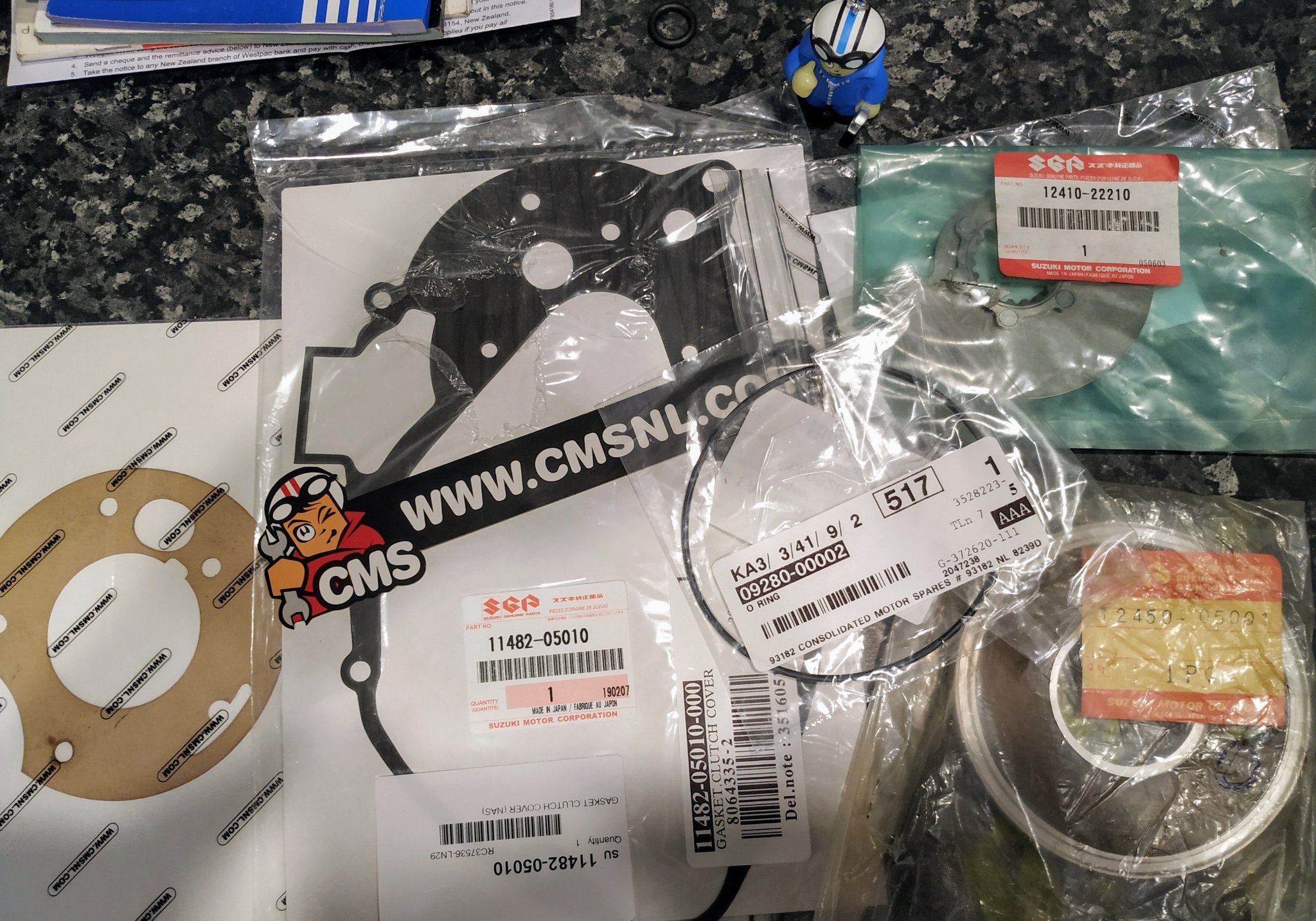

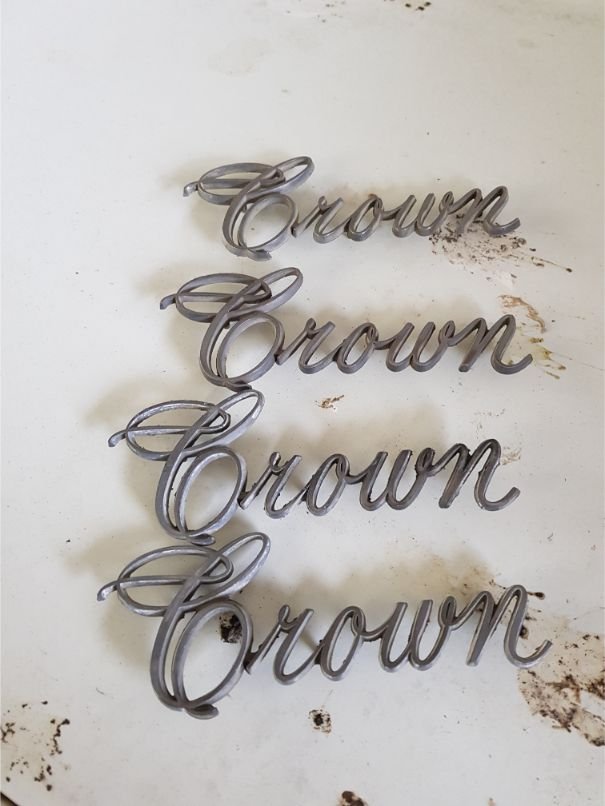

Probably have more from the build I can post, but not tonight. Have had issues with a nasty scraping clicking sound from the engine, at first I put it down to top end noise and tried to ignore it, but last time I had the cylinder off I got the Mrs to kick it over and the sound was still there, following my ear I'm 95% sure it's coming from inside the disc valve assembly. I'd noticed that at some point someone had munched up the heads of the 5 screws holding the inner valve plate in and the cross's were all jagged and rubbing on the plate, I replaced them when I put it together but the disc has a few decent gouges in it. I'm hoping the solution arrived today. Looking at the SGP stickers, there's NOS from the 70's, 90's and fresh new parts. Going to attempt cutting the disc for more nangs while I'm at it, have found a few timing specs to go off, so fingers crossed it works out!6 points

-

5 points

-

12-11-19 @johnnyfive @Vintage Grumble @MopedNZ @GuyWithAviators @Shakotom @cletus @tortron @datlow @keltik @Truenotch @TimShadboltfan27 @WankBankA100 @BLIZZO @MaxPower @Dolan @Mitch.W @Tumeke @Tumeke's brother Brett @UTERUS @Ned @RUNAMUCK @Zeubin @Atex Lee Dan Shannon @Deano Mike @mark105 @Geophy @Duke Blackwood @Geophy's Dad @peteretep @Beaver @Archetype Lance/Julio Ryk Chris/Tofa @anglia4 @anglia4's Dad Paul ThatSlowGuyOnTheRuckus/Dan @slacker.cam @sentra5 points

-

Wife gone out so back in the shed. Cleaned the engine block up but the paint pretty much fell off and was quite rusty under the grime... So 5 mins with a wire brush gave me this... and bombed it with some primer... Will paint it black if I find some suitable engine paint tomorrow...5 points

-

Yeah exactly. Theres always a stupid overhang detail like this that makes it harder than it should be!3 points

-

So I had a conundrum with the shifter where I could run it back to front and it would work easy but the shift direction would be reversed (race shift) and I HATE race shift, so I opted to engineer a new shifter linkage, sources tie rod ends etc and then Dad Blackwood was like “why don’t you just pinch one from one of the spare bike frames lying around?” So we did, and with little modification, it fit like a glove. Thankyou FXR150 frame haha. Also repaired kick starter and locked in a lot of the wiring, just have to repair fairings and install an Oiler really and we’ll be rolling for Rego! Pics to come3 points

-

3 points

-

My little ol town was covered in the sweet smell of Bogan(red neck?) perfume recently (tire smoke). The Waimate 50 NZs longest running street race was on for three days. Got to hand it to the drift boys – put on a wicked show. Primed up the old Nailhead. was so easy. With in 30 seconds oil started dripping and after a min or two of constant oil pressure we left it at that. Dropped the front seats back in – good old mexican blanket covers a world of horrors. Front fenders on, fluids added and it was time to push the old gal out the door to get a few pics and then finally turn the key. Oh My Golly it was an exciting time I tells ya. Sitting nice in low. Below is not even the lowest part of the car With the chief garage cat supervising on. We turned the key… engine turns.. oh so exciting ! the starter at least works and we have oil pressure!!! Then after VRROOOMMM it starts! no messing about it just roars right up. no feking about with anything at all. Happy grins as the un-capped exhaust loudly roars. …. hmm whats that I hear… Clunk! clunk! clunk! engine off. Kinds sounded like down below. hmm guess the crank weight was pointing up and wasn’t noticed when this was fabed up. bugger. Cat was about as impressed as I was. With that culprit removed and confidence high we start again. tick tick tick…. phuze nut! turn it off, shove some wet rags in the side pipe openings so we can hear better. https://drive.google.com/open?id=1KNN_1E4qhxXvlvvJkmMiKFL15qixBPxu Yip its ticking. cant seem to track it down and didnt want to leave engine running till we talked to engine builder. Drove it into the garage. Draining the oil. Builder says it could be the lifters. Doubts bottom end. But recommends we carry on with the Run In procedure. And see how it goes after. Will pull the pan and have a look. Will pull the rocker covers as well and run my eye it all as well. on the bright side… if it is lifters I can use it as an excuse to get a new cam ^.3 points

-

2 points

-

Is it because the corners need to come out before the rest can be removed from the sand?2 points

-

My britool tool chest from the 50s is like that. It's a period correct coating. Just clear over it2 points

-

Don't lie. We all you know you've got their complete works stashed in your phone at all times.2 points

-

2 points

-

2 points

-

2 points

-

2 points

-

This is running again. with some some mixed results. Makes the same power as the old setup, with almost identical power curve. This is good, wasn't expecting it to make anymore power. runs nice. Swapped in the big inlet cam. As on old setup made another 15kw on same boost, but ran junk. (see top of this page) Ran better on this setup but still rough idle. Now where it gets weird; Had to add a decent amount more fuel, but only had very small power gains over stock cams. Tried all sorts, no dice. Still unsure whats going on. Ended up swapping back to stock cams. One major benefit of the itb setup is how well it runs down at idle. before with the big plenum and single throttle it would stall out real easy. much below 1000rpm and would just die. now it will go right down to 500rpm and keep chugging along. Have also added a simple on/off air bypass solenoid. programmed for idle up on cold start and when fans come on. Also doesn't vibrate it self to bits like the old setup. Still need to fix and tidy some stuff up. plus finish the tune. then im a gonna go destroy the paddock Next up steering servo for full scale rc hilux:2 points

-

2 points

-

Had me puzzled about the point of the corners.... Thought about it for a bit.... Wow thats fancy! Love your work1 point

-

I've got both factory seats and will probably roll those for the wof. Pump up lumbar support is lush!1 point

-

Sorry my use of terms may have been off. Just passing on information I recently accuired I'm August I had several conversations with a repair certifier. He was very specific that all structural repairs need to be performed by a qualified welder and proof had to be provided of the qualifications and of them performing the work. A d he pretty much told me that most of my car was structural work. I asked if I could do it my self if I provided evedence of being a competant welder and was in no way possible. I questions if this was a recent thing as I thought that I was able to do it my self. He said things changed acouple of years ago. He even said he could point me in the direction of courses that would provide the minimum stranded required. I did not ask any more questions after this as to the exact details of the qualifications needed. I started doing maths in my head and quickly worked out my she'll was not going to worth fixing for a road car. There must be unit standards or something simple that must be held1 point

-

Yo Johnny I think us ppsc dicks are Ken to stay st your pad Thursday night xox prob can tent camp on ya deck/dick/sleep inside the landy in ya shed if that’s ok. Kisses purple goanna walrus made my teeth hurt heck1 point

-

1 point

-

Yeah something like that would be good, try get here early enough to give yourself time to unload, fuel up, pack your bag, chase that fault, top end rebuild. You know1 point

-

1 point

-

So entered this ol thing at the Smash Palace Bike show this yesterday. Seen a bike show near Gold coast earlier in the year and all the bikes had thier own displays so took some inspiration from it and I created a display that was fitting to and a Monty Python skit Im a LumberJack and im ok. I work all night and sleep all day. Quite fitting for me as ive worked night shift the whole time ive been building this bike. So I scored some wood chip from work and a few rounds and put a Axe and Saw into them and had this as my displaye. I won MVP of the show for my display which I was quite surprised about.1 point

-

1 point

-

1 point

-

Is anyone going to have WOF & Rego? Surely noone actually rego's a motorbike...? React trophy for Yes. Laughing for No. Edit: can't react to my own post but1 point

-

1 point

-

Very nice. The Americans might have invented the drive-through, but the Brits invented the cupholder to make it civilised.1 point

-

The Bluebird was used for gymkhana hence the note. Anyway the MGB next to it (same owners) was in work last week and it was mildly amusing informing the Police officer owner that the internet thought he was a salty old munter.1 point

-

Hmmm, that'll make changing the tyre a pain... Perfect! But then the K50 cylinder came with this: And just to make tyre changes easy Dropped it 25mm, ended up with the swingarm level, which for some reason is pleasing to my eye on any bike1 point

-

So this thing is still in a million bits, I'm still in the process of painting. All the bolt on bits are done, just have to finish and paint the frame. I wasn't happy with the battery tray thing, so going to redo that with a box of some kind. Story time: So a long time ago I got plans for one of these, I started collecting parts, but when I realised the cost and time involved in building one, I canned the idea. I had already purchased a second hand set of front callipers/discs/stubs from one, but the guy kept the hubs. Recently Edge products in OZ had a sale on, so I ordered the missing hubs, so I now have the compete set up. So sometime in the future I will make new front arms and put these bad boys on. I'd like to put flasher shocks on all round too, but they are spendy. Ages ago I also got a nice set of alloy rims and tyres from a racing ATV off trademe, they were listed retardedly so got them super cheap. And in a stroke of luck, the front rims are the correct PCD for the new braked hubs, neat. The back rims don't fit on the current hubs, but I've started collecting parts to make an independent suspension set up for the rear, so will make new hubs to suit when the time comes. Other than that, I've drilled some big ass holes in the 12mm plate at the back, to try shed some weight, and make it look racey. I also got offered an absolute abomination of a go kart for a box of beers, so got it against my better judgement. Its based on a kawasaki quad with a weird name that I can't remember, has front discs even. I'll probably just keep the front suspension and steering, rear axle and all the wheels, and bin the rest as its super grot. Plan is to make a simple two seater for the wife n kid to blast round in. Probably 13hp lifan with cvt set up or something. It has a 2 or 300cc honda atv engine on it, chain drive with low range, if anyone's interested? Regards, VG.1 point

-

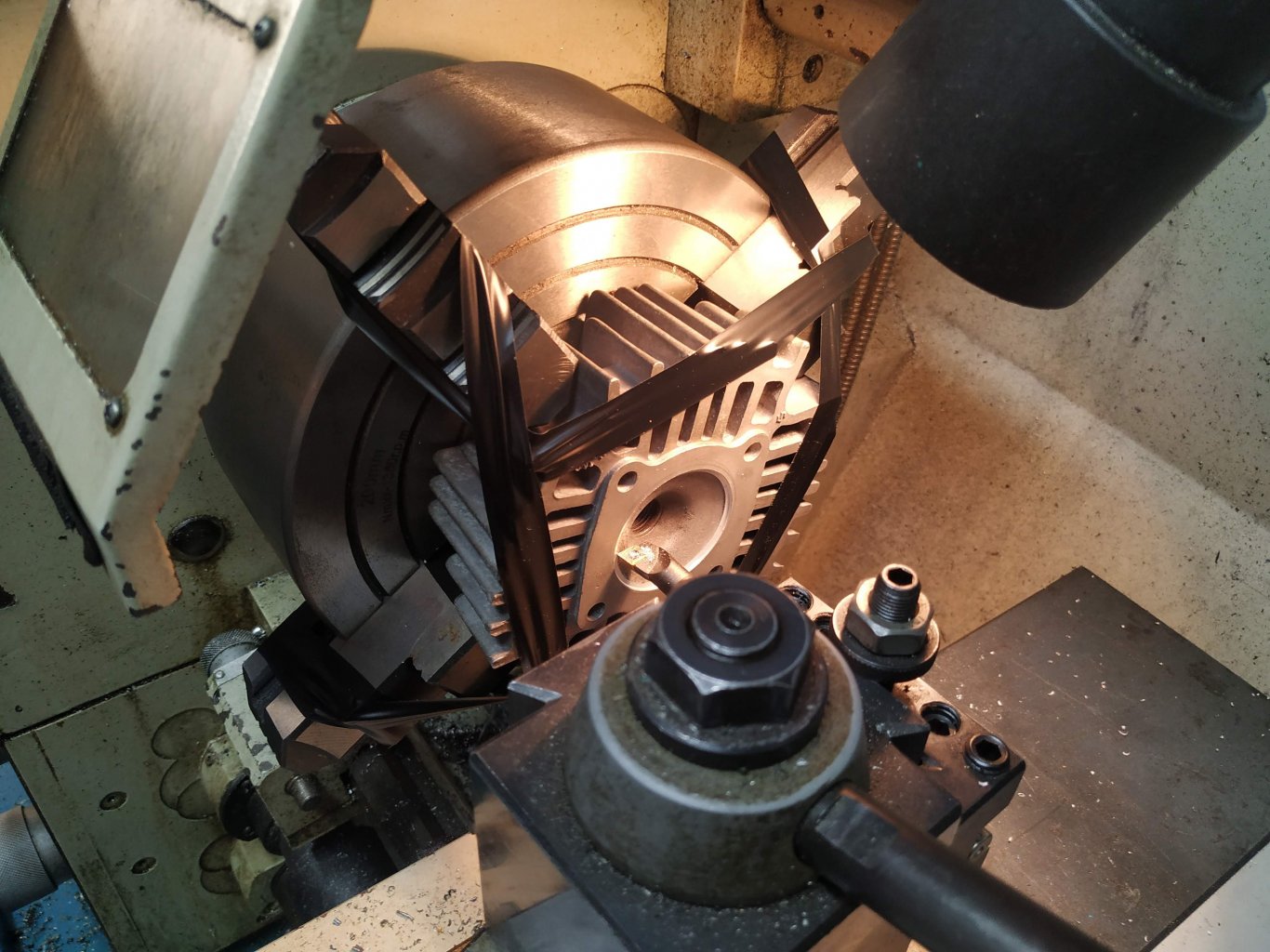

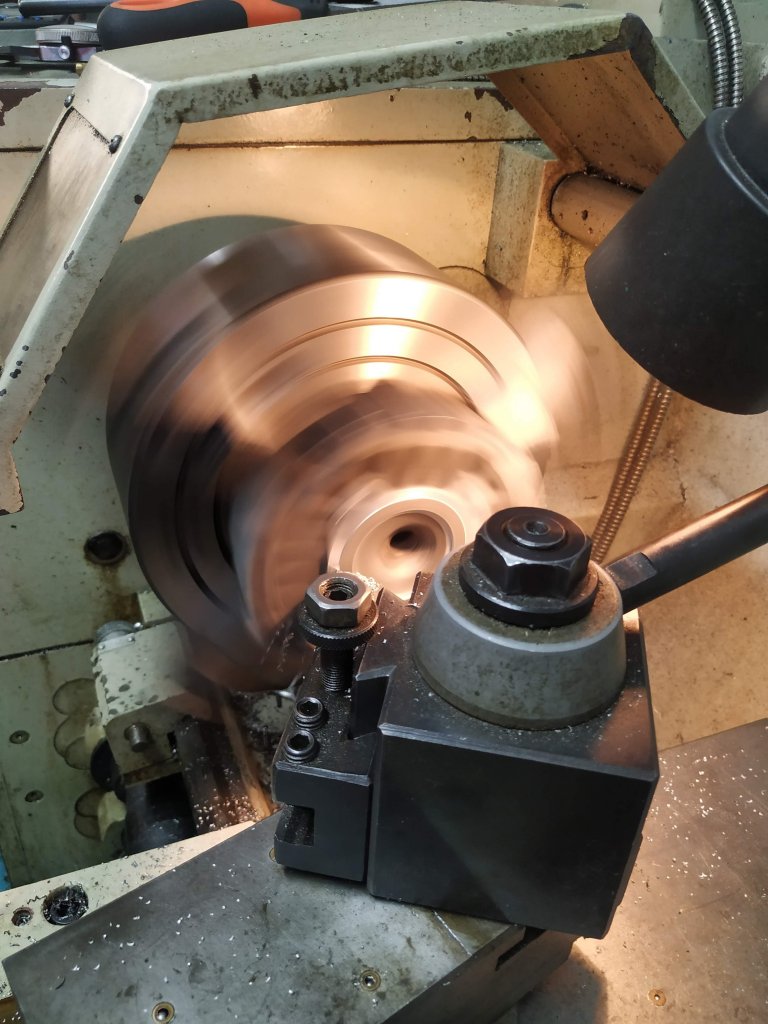

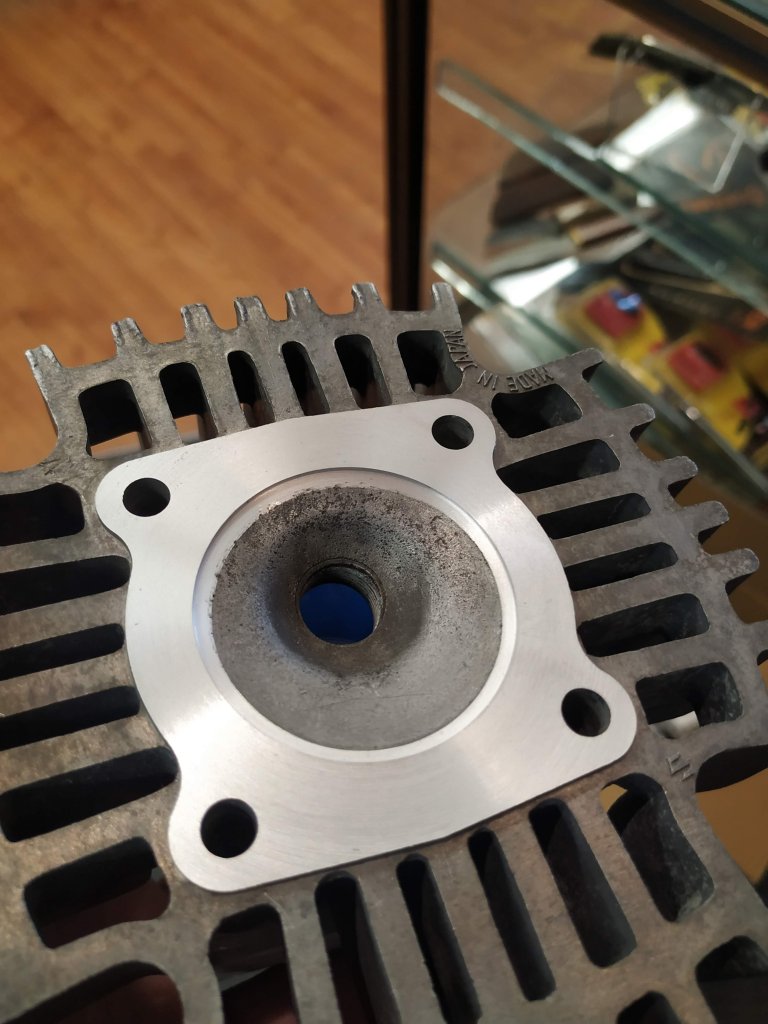

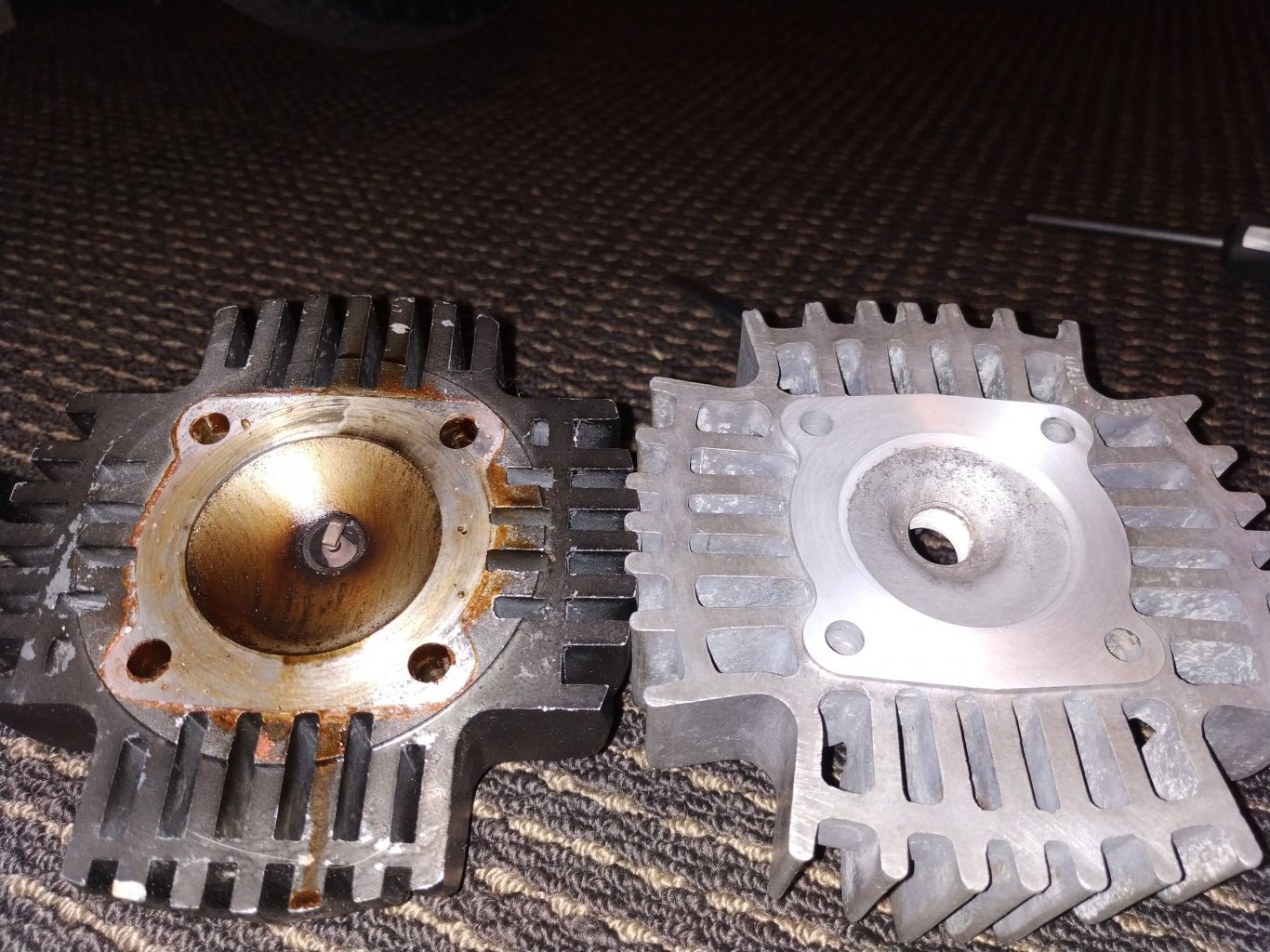

Back to the engine, 120psi-ish and zero acceleration in fifth or on any incline wasn't going to cut it!! Soo back to the lathe!! That's the factory 41mm bore head, added a 2mm squish band to take it out to the 45mm it needed to be to suit the cylinder and also took .5mm off the face for luck! Can see just how much deeper the aftermarket finned soup bowel is! And the plug after pesting about in Auckland, looking a touch rich if anything. So added another .45mm base gasket, .4mm head gasket and ended up at .86mm squish with the refreshed factory head fitted, looking for some .2 copper sheet to make another head gasket out of to gain just a little bit more nang. Much better! And I think it would have come up a bit higher if I could have got the rubber push in fitting to seal better in the plug hole. Drastic improvement to power, shift at the right time to keep it on pipe and it will pull to the top of fifth now! BUT now that it has compression it wants a lot more fuel!! Have to order some pilot jets from MikuniOZ for it as once warmed up it is running HOT and has the worst lean hang I've ever come across Suzuki used a non adjustable version of the Mikuni VM16 so there's no screw to fiddle with to try and make it happier in the mean time, so a little A50 waits again as I've put too much into this thing just to melt it down in the quest to pest! Oh and as it turns out, having more than 6 and 8 or so psi in the tyres really improves acceleration... Who'd of figured... Think this post has the engine work pretty much up to date, until the bits I ordered yesterday arrive in NZ at least So here's a pic of @Archetype hard at work transforming the whole look of the bike1 point

-

So as it turns out there is NOTHING in the way of a big bore kit for an A50 available, I can find listings for them from no later than 2005 so a bolt on A50 kit quickly became not an option. But I did discover that until recently Suzuki made another model, the K50 that was essentially a 3 or 4 speed low power version that was popular in Europe, main difference seemed to be that the K50 used a reed valve set up instead of the rotary disc valve found in the A series. Pics looked good so figured the 45mm kit would be good to go, so I ordered a kit from Denmark along with a new head, center stand, kick starter and other bits, also learnt that Danish KR is worth almost twice the NZ$ of Swedish KR Looks good right? Wrong Close to throwing a cover over it and walking away for a while a mate took my factory cylinder, welded on a new fin and said he'd hone it out after I ported it to try and get rid of at least the worst of the chamfering gouging. WIN! Or at least a win until I started trying to port it... The cylinder wall was paper thin and crumbly between the bore and the port, even a light touch with the die grinder just ripped chunks off So back to the K50 option... Black K50, Green A50 CNC plasma cut adaptor Cylinder skirt hit the crank webs and the cooling fins fouled the engine cases, so a bit of high precision engineering took place Cut a couple 1.6mm base gaskets to get the port timing right Not great! But we can fix that, we have the technology The kit head seemed to have come from a soup bowl factory Close to 3mm came off that! Fitted the clutch cover etc and gave it a couple kicks to check compression Not great, but better than the factory 95psi rating at least. Fired it up at 10:30pm one night, in the house, using air freshener as engine start so I didn't break my Mrs no petrol or engine start in the house rule... 2nd kick and it burst into life!!! And since it was so late, the exhaust port was all the exhaust it had and I didn't warn her, my Mrs just about had kittens hahahaha Spare room smelt like a warm summer breeze and I'm now banned from the air freshener, but I was so happy to hear it run!! Next day I fitted the pipe and pushed it outside, tipped a few liters of premix in and ran it for a couple heat cycles, once the rings bedded in a bit compression came up to closer to 120psi too. Fuel tap leaked like a sieve though. Sorted! Still a bit more to cover on the engine, it's actually still an ongoing thing, but you've read enough of my drivel for now lol1 point

-

Just took the photo of one car this year. Wasn’t even that tidy. Missing hubcaps, coupla scuffs and primer patches. The note on the windscreen just made it for me though, can imagine the salty old munter whinging at club brass going “it’s a historically significant 50th anniversary edition m8os, ya just don’t see them anymore.” Was tempted to leave a note under the windscreen offering him a straight swap for a mustang convertible.1 point

-

Sorted the loom out for all the sensors, coils and injections. really liking the fuel rail cable support! starting on power harness witch is a bit more tricky without it being in the hole. going to move the battery to the intake side. Witch should also free up room on the turbo side. Try find a large OEM filter box that fits in there nicely. maybe something off a later model 4wd with snorkel and large panel filter1 point

-

1 point

-

1 point

-

I dont know wire cutters but can give file to anyone here who wants it. Ill put in cad library tonight.1 point

-

I have an account with laser cutters so could even get it done for ya1 point

-

could get a few of them laser cut from 5mm plate and stick/weld them together? The teeth don't need to be super accurate?1 point

-

pretty sure its a power to weight/general weight classification, give me a week and ill know alllllllllll about that stuff. but no more gas turbines i really want to put a helicopter engine in an old car, hooked up to the gearbox1 point

-

The 360 need a tuneup, 'cause my buttometer was telling me it was 5-10hp in arrears. I happened to have access to a portable oscilloscope, so here's the results from last weekend Here's the -ve terminal of the ignition coil. It's a 4 lobe cam, so 4.5 divisions x 5ms x 4 lobes = 90ms per rev. 1/ 0.090 = 11.1 rev / s * 60s/min = 666rpm at idle. Problem is that the points are closed for ~12.5 ms / 22.5ms, thus ~55%, thus 55/100 * 90 degrees = 49.5 degrees. Dwell angle is supposed to be 47 degrees (Working from memory, will check later). This is the same adjustment, but revving faster. The timebase of the scope has been set to 2ms, and you can see the 'ringing' AC as the energy sloshes from the inductance in the coil to the capacitor on the points when the points open. I got in there with a feeler gauge, and the gap was around 0.25mm. You can't see the top of the waveform in these pics, but the peak voltage is 150 - 200V (yep, on the Low Tension side) and gets multiplied by the coil / transformer ratio for the HT side, thus 150V x100 = ~15kV. Usual insulation gaps are around 1kV / mm, so thats getting a bit iffy. The manual for the engine says 0.3mm - 0.5mm gap. I polished the faces of the points to get them square (they form points and dips because of ion material transfer), and set to a shade over 0.3mm. This gave the waveforms below. Basically, you can see they're low (closed, i.e. dwell angle) a shade over 1/2 the time, and now meet the spec. A little grease on the dizzy cam lobes for good luck (it was dry), and then on to timing. Because I can turn over the engine by hand, I put a rod on the piston, and checked that the timing mark on the crank pulley was correct. Then I turned on the ignition, and rocked the engine to see where the points opened. This was easy, a nice satisfying snap from the HT as they do (don't run your HT open, kids, the V's can get too high. I had plugs fitted.) The ignition had been about 8mm too advanced (I'll work out that timing sometime later) and when set to factory spec, the machine was transformed. It now starts easier, a bad hesitation in mid-range is gone, and it revs out in the 50-60mph range much cleaner. Detail. It's all in attention to detail.1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpeg.384ff72c8d2b0ee0d34a7bdedb55bdcf.jpeg)