Leaderboard

Popular Content

Showing content with the highest reputation on 07/15/19 in all areas

-

I also got a new friend for the wagon! just need a coupe now right? Its the best starting L series i have ever seen, low kays, been in a shed 15 years, immaculate interior. Undecided if i will keep it. might start a build thread9 points

-

6 points

-

Gave it a wash and drove up to auckland a few weeks back. Came up pretty shiny. Fitted some new shocks to go with the reduced suspension travel and its lush again. Had a few funny issues at first and stopped and gave all the spade terminals on the coil/ballast resistor and away she went. Sat on 70mph the whole way, even passed a car up the mahoenui hill at more than 70 Also, gotta catch em all!6 points

-

Use their own shipping. No need for third parties. Try and keep all your items from the one warehouse and you'll save money too. You can't always of course but it does help.5 points

-

Proof that I am now an auto sparky and fuck anyone who says otherwise; Should have cleaned the smeg off my lens for that last one. Then on to the engine cover, but first I had to build a bit of the intake to make sure I could get it all to clear. There is a sweet spot just behind the cab that will fit a 600x 300 intercooler, I am hoping I can get to that area without modifying my gear linkage too much. Made a rim for the cut sheet metal so the floor was stiffer and the cover had something to bolt to. The intake had to be low otherwise the folding rear seats would hit it. Welded and cleaned up. Looks kinda cool. Then some time honoured 'frame it up in solid round then smash sheet metal onto it' fabrication. It's tight. There was a wee bracket thing that hit the cover when the seat was down so I whipped it off with the grinder only to immediately realise it was the hook to keep the seats up. So now I need to replicate it. Like a cunt. I initially used some real thin galv sheet I had but it was clear I was never going to be able to fully weld it without chasing holes all over the place, plus it already sounded clangy and tinny, so I found some 1.5mm mild steel in the rack and used the thin shit as a template. This meant I could get a nice fold where I needed it using the finger bender. Still yet to do the other side and fill in those gaps, but good progress. Front driveshaft assembly is in getting shortened and balanced at considerable expense. Still yet to hear from engine man. I might have to spend that money on coating the chassis etc and hope I can find some more later on. Or find some more shit to sell. As you were.5 points

-

4 points

-

4 points

-

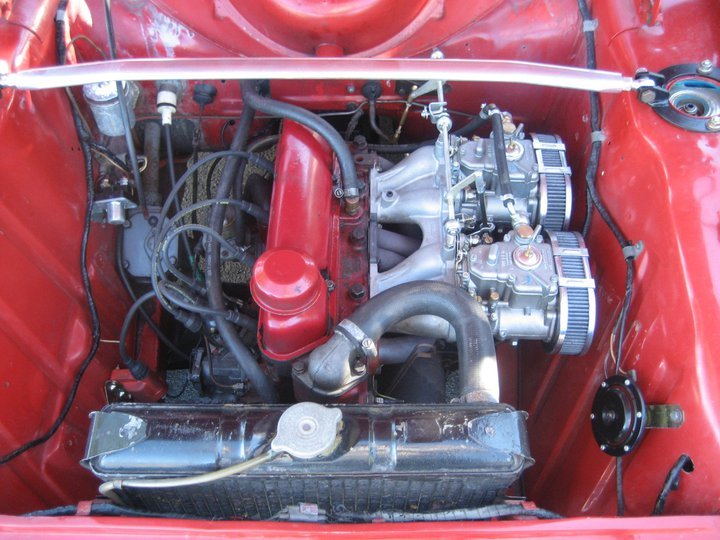

next step is the head. i have been gathering up parts for a while. some manifolds and carbs etc here chose a manifold to run and started matching up the ports and chambers Got a couple sets of carbs and rebuild kits, but decided that efi was the way to go, so gutted a pair of them, pressed in some aluminum and bored the centre out. Have fitted some injectors but havent taken pics yet. hope to finish the head in the next week, and get it to the shop for a skim. I got to get my act together, the family is coming with me to chch for nzdatsun nats in october!4 points

-

- made up an exhaust support from the gear box to the bit before the flexis, similar to how the 125 is set up - put a blob of weld on one holey weld (one! ) - took it for a hoon. Sounds great from inside, very quiet on cruise but a bark on the throttle and right at 2000 rpm and 4000rpm - rear pipe was touching the tow bar so adjusted the donut joint. - You can see the Y joiner at the rear seat, thought i may have needed a muffler in this section but it will hopefully be fine Only one sunny day this weekend, so did a few other little jobs, - after coil and resistance chat earlier in the week i checked the voltage at mine, it was about 10v. Based on googling its number to find out its specs, i think its a Ferrari or 6 cylinder Alfa ? came in a job lot so iunno) its quite a big larger diameter than usual anyway. Didnt even get warm on full 14V checked it after a exhaust sound test run . Si used the power from the fuel pump relay (already triggered by the factory coil feed) to power the coil and it seems a bit less missy when cold. Which reminds me I need to get a new Magnetti Marelli dizzy cap - there are cheaper versions out there but they are not very good. - also adjusted the idle mix on the carb a smidge richer, and i could slowed the idle speed a little more too. Engine now ticks away lovely, with a nice burble that you can only hear from the end of the exhaust, i think that the old one had quite a few more holes i didnt spot. - gave the headlining a scrub, and pulled out carpets, removed rubbish etc. - Put in a pretty subtle magnetic phone holder. - Gave it another wash, and then a wipe with an old polishy towel. Needs some more protection. I reckon its ready for a run to the WoF man one day soon.4 points

-

Made a start on the plenum I tested the trumpets on the starlet. red line is straight pipe the same length as the bellmouths (blue). Pretty much no difference till airflow demand is high. after that the bellmouths win. Down on power about 10kw to what starlet makes due to runner length. Some goose put a massive suspension tower in the way, so stuck with this length on the hilux3 points

-

3 points

-

Video of first start. Is a credit to Al Marsh. 8 year old build, he never had a worry, I was stressing, but oil, water, fuel, and spark, and he was just like "go for it" he never doubted his build. https://www.youtube.com/watch?v=Kxpfsu5Z9ns3 points

-

Seems im overdue for another update. Best remedy that I guess and spew forth more pics.To keep all the electricals ticking im using a Powermaster 150amp 1 or 3 wire alternator. As i stated above I wanted all the brackets as low as possible. unfortunitly cooling hoses got in the way in the middle positions and the powerstearing rack when it was really low. So its had to go up higher but is still low as we could get it. Still its not to bad I guess.Also mounted up the radiators overflow seen above.On the other side of the rad we mounted up the PS/hydroboost reservoir. Three port jobbie.Under the car a fly wheel cover was fabbed up. Stock would not work due to the trans adapter. Bit of split pipe was used for the notches to clear the torque converters covers ridges.Car is off the jack stands and front panels are bolted on. not all the bots etc are in but enough to keep it together until I get new bolts for it all and get it done right. Old Nailhead sits in there nicely.Steering wheel thrown on just so we can roll it about easier. GT Performance 9 bolt hub, 15.5" wheel and horn. Really wanted a wheel with a horn ring cus I love those things but ones that suit smaller wheels are bleeping expensive so it can wait.Car is sitting pretty darn low. Like the lowest part is the brace that joins/strengthens the front sub side to side much like the original Hudson setup. I haven't measured it but I guess we have 30-40mm clearance to the road. As you can see with the good old beer bottle next to the car... it low.keep in mind we still have to add side pipes - its that big ol hole you may of spotted in the above pic. You will see also that we will have a heap of room for them under the rockers. They also have a bit of a curve whats a bonus as it will (with luck) keep them out of ankle range whilst keeping them nicely tucked up so we dont rip em off.and moving right along... side shot just cus I like it. yes I know the car is dirty but so is my mind and I like it that way.Now talking about burning ankles on side pipes a subject by gal has mentioned most times I bring up lake pipes. My answer generally goes along the lines of "wear heels" below pic proves it. Ankle out of burn range.. toes on the other hand she has never mentioned.But seriously - like the back tire viewed air out side on.Enough farting around talking about air out this and that. Throw a battery in and test that shiz. Yip yours truly testing it out. We left it air up for a few days and I was pleasantly surprised to find it stayed there with only a few psi drop from what I left it at uniformly across each wheel. I will mark that to atmosphere and not any slow leak due to it being across all four wheels not just one.yeah i know the front could be bolted on a bit better but ahh stuff it it will be off again anyway.And just cus im feeling all gangsta...i know it aint hydraulics but it will do me. When air up we must be around 150mm at that one low point in the middle just behind the wheels. Ass end that has larger bags naturally goes much higher.3 points

-

2 points

-

I dropped a bunch of coin there last night and didn't know about that. I used to get rotors skimmed for $20 a pair. So that was my go to. But now that ship has sailed, and a mechanic at work said yeah, thinner discs have less thermal mass and will tend to want to go wobbley again. And new rotors are so cost effective I just say fuck it now and go new. I got stung $90 to skim two last time. So that's a big game over cobber for the skimming guy from me.2 points

-

You throw stuff in your cart and then it'll have little truck icons with letters or numbers on them to indicate whether they are from the same source warehouse when you're browsing for more stuff. Pretty neat little feature.2 points

-

I had a yarn with a @GuyWithAviators, @Geophy @EURON8 @Chickity @bathcollector And @73crownwagon spent $20 and aqquired a great/yuck Batwing billet style steering wheel -inner chip foose pine, some old yellow lensed fog lights and a rx125 manual for Nick Ritchie. Chips with speedway sauce and an average coffee topped the event off. Would trade again. Had a monkey bike in the boot of my car, so was v.limited with space. Saw some lush Harley bits, couple of old bikes, lots of rusty bits and many ol barrys there for ‘a damn good look around mate’2 points

-

Thanks guys, appreciate your advice. Crazy how cheap some places are selling new replacement parts. Found an aussie website selling 2x new front rotors for $85 including new brake pads, or $60 excluding pads. And they ship to nz! So I think that's what I'll do, as I can wait a few weeks.2 points

-

2 points

-

2 points

-

and ended up with me getting to do this. https://www.youtube.com/watch?v=ddwY1EinaO82 points

-

fuel tank boot floor time.... i wanted to change the tank as the cortina one was stuffed so i looked around and decide on a 68 mustang brand new was $210 landed..and that meant losing the boot floor wheel well (didn't like that anyway) it was in good condition and got blasted with the shell so i advertised it and donated it to another build. so i started with a massive hole in the boot and decided to use some box section and the main brace after i welded it up i measured again and found out i stuffed it up hahaha.....measure 6 million times kids and cut once..so after i cut 100mm out of it i welded it back up again so after getting it right i tried it in the hole...apart from having to cut a 45* off the back corners for the chassis rail it fitted. and i welded as much of it in as i could. then it was time to make new floor parts....starting with the rear part. then the passenger side then the drivers side. then made the 2 caps for the back corners from where i had to trim it for the chassis rails. then a quick clean up throw the tank in to see if it fits2 points

-

Hi all. I thought it was about time I started a thread on my Hako. Please go here to tell me your thoughts..... //oldschool.co.nz/index.php?/topic/51341-karol-shusbands-72-skyline-betty-the-hakopotamus-discussion/ There's not many cars that you can remember the exact first moment you clapped eyes on them. In this case it was June 2004 and I reckon it was likely to be a Saturday. I was probably avoiding doing something important and playing 'Gran Turismo 4 Prologue'. I had unlocked the bonus 'making of' movie and was watching all the JDM goodness when all of a sudden a car jumped out of the screen at me. I had no idea what it was but I knew that I had to have one. It looked a bit like my mates 69 Dodge Coronet and was obviously Japanese. At this point in time I hadn't ever owned an internet so it was off to my parents house and I started googling '1970 Datsun/ Toyota/ Mitsubishi', etc and eventually found this picture on a site called jbskyline.net. I then started reading up about Nissan Skyline GTR's and soon realised that I couldn't afford one. About the same time I discovered Japanese Nostalgic Car and kev's car. No linky to post coz JNC is broken but this is the car. Kev's thread was an education and I got my head round the K's, G's, C's and P's and the number 10. I also realised that a 2 door GTR look-a-likey was was I wanted in my life and at a stretch I could get one. Watanabe's were a definite and the car would be silver or even better, white. So that was that. I knew what I wanted and all I needed to do was order one from one of the many Importers and It would be here in a jiffy. Sorted ? Nope. More next time1 point

-

Hi All, Have been a member of the forums for a while but haven't contributed a lot. Went along to the monthly meet in Ellerslie last week for the first time and met the Escort brigade in the pub. Someone suggested I should post to introduce myself and my car so here goes. I bought a 1064 Mk1 Cortina GT in 2011 which looked like this at the time. Turned out the engine needed a bit of work so I decided to go for a YB engine. It has taken a lot longer than I had hoped but the car is now not far from being complete. Fingers crossed it may be on the road by the October monthly meet. Will post some more pics when I work out how to resize them... Cheers Nick Discussion- //oldschool.co.nz/index.php?/topic/50272-sods-64-cortina-cosworth/1 point

-

Owning this thing has been very fun! On my first day of ownership i thought i'd go for a ride with some tractor and saddlebag enthusiasts down Central Hawkes Bay to the Patangata Tavern for a shandy and sharn. After fueling up, the battery died on me which i thought was odd. at least i had plenty of big hefty harley riders to give the only japanese bike in the group a push start. I quickly learned that these bikes do not like running with a dead flat battery. After a while it wouldnt even push start, which left me stranded somewhere on highway 50. thank god for AA plus! The previous owner had told me the bikes battery would go flat after a while if not riding it often, these old bikes tend to have pretty tired charging systems so didnt think much of it. Didn't realise it would shit the bed within a day of owning it... Started with the regulator/rectifier. a quick diode test showed it was chooched. A second hand article was had from a wrecker in chch. The bike now held charge, but every time it started up it would blow the main fuse. I found some helpful info on the GS resource forum, which helped me diagnose a faulty stator. A common issue with these bikes, as they are tiny, dont get a lot of cooling from oil in the cases and are just generally shit. tracked down a local replacement. Its a Ricks Motorsport Electrics aftermarket jobby. the thing is super beefy and has like double the copper windings on it than the factory article. Now just waiting for a gasket for the stator cover and can finally start getting some more miles on it! yay for old shit1 point

-

Cheers to absolute legend @crustywhip for sorting me a whole box of interior trim, door rubbers, windows, regulators, and most importantly two mint front guards, one of which has already found it's way on the car. Cheers to @The Bronze for hauling the bits up the country for me. Now that the front is together, only minor things left for a warrant. Need to stop annoying exhaust rattle, put my new front calipers on, and get the headlights working again. Front guard will be painted at some stage but for now it's not too much bother. goes so hard. I get many "when is it getting a turbo" comments, but for what it is it definitely doesn't need one. till next time1 point

-

1 point

-

No, you just take off the high spots. Fix the grinder to wood jig or something, not by hand.1 point

-

Years ago I had some machined while still on the car, they had a fancy machine to do it. Recently I asked the wof guy to check the brakes on my wifes car because I could feel a wobble under braking. They were a bit warped, he reckoned better off going new because warped ones are likely to warp again quickly after machining. I guess it makes sense if they are unevenly heated when warped?1 point

-

Silicon spray from mitre 10 Bunnings has it $0.06 cheaper so they will knock off 10% https://www.mitre10.co.nz/shop/selleys-watershield-water-repellent-200g-clear-colourless/p/3248131 point

-

with places like https://www.rockauto.com/ and a bit of waiting your gonna come out on top with new disks just about every time. As a apprentice we would take hand full's of vt-vz commo disks down the road to the the shop with the brake lathe and exchange them out for ones hanging on the wall that were all done. It was kind of ok as the economies of scale worked... but new disks in this corner.1 point

-

rust..... you'v clearly never encountered datsun ownership. but datsun and thousand dollar supercar were never men't to be used in the same sentence anyhow.1 point

-

Well she's back up and running again. Head went back to engine builders to get some shims installed al align the adjusters more to the center of the valves, added more of a radius on the adjuster, changed the type of oil I am running. Found the new valves have more of a contact patch on the valve also as the original set had a large chamfer but the new set is much much smaller. Hoping with the above modifications it will not happen again. Engine builder seems to think the oil I was running could have contributed to the issue.1 point

-

1 point

-

These new wheels have a tyre diameter 3% smaller than stock, so my speedo is even further out than before. It now seems to under-read by around 10%, officer. I went looking for more reasons for the vibration at 80kph, and found the diff seems to leak oil from the input seal. Probably explains its woooo noises on deceleration. So many things to fix! This car will keep me entertained for many years. I found a bit of play in the front wheels when rocking them at 12 and 6 o'clock, but not at 9 and 3 o'clock. I ordered some lower ball joints (an unscientific guess) and installed them this weekend... While doing this, I found the shock absorber top mounts were loose, one by a reasonable amount. After replacing the ball joints there was still some play in the wheels, so I think I guessed wrong. The vibration situation seemed to have improved for some reason though. Maybe I need to do the upper ball joints too / I don't know what I'm doing.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

So I turned a Accumulator groove into my pistons. Its a groove machined into the ring land between the top and second ring. This groove accumulates residual gasses from combustion to stop ring flutter improving ring seal. I also added some Contact Reduction Grooves in the top land these limit piston to cylinder contact during high rpm and high temperature. They also disrupt detonation waves. Now I've pretty much got most of the bottom end machined except for the valve reliefs. But to machine these I need to figure out what size I want to make my valves. Here's a picture of standard valves vs some oversize valves. I won't be useing these particular valves. I will make some valves out of Mazda/Ford FE 8v valves. While the head was lying around my work mate Al decided he would do a little porting to open up the intake runner where it pinches down at the intake manifold face. You can see he has opened it up enough to be able to run the calipers down the runner to the bowl area without it pinching the calipers this tells him he's got it pretty evenly round. This should give good even area volume. So the intake flow stays at a even speed. Before hand you would expect the intake flow was speeding up through this area then slowing down before getting to the back of the valve. Hopefully I explained this ok. I'm no guru on porting. This is just rough cut off the burr. We will probably leave it that way as it can help in atomization.1 point

-

1 point

-

just using short silicone hose on my na setup, works fine. will do the same on this missing the hose clamps in this pic1 point

-

1 point

-

finally adjusted the clutch pedal properly relative to the master cylinder, the various adjusting nuts are very high under the dash and not made for human hands. Yay. However in doing so i broke the light switch out of the column, with my head. This is the third? time ive done this, the car cam with no end of hacks to get around the broken one it had, i got this off another 2300 nut as his spare, and it broke in the box on the way home, you can see the lump of JB weld on the front indicator To be fair they are pretty weak design relative to the spring and ball bearing they act against, and with the plastic being so old they just bust out. ITs also a special snowflake* because it spaces the column change ball and the outer steering column, so we must make do. (* for Eg found this NoS one http://www.epocacar.com/shop/en/internal/8933-devio-luci-fiat-2300-s-13-fili-nos.html for 213EUROs and its not even the one in my ca, its the one in the book ) Good ol JB Weld, (other epoxies are available), tricky to get them 'moulded' without slopping it down into the guts as well, but the old tape dams and several thin layers did the trick The 'ear' had also fallen off the indicator switch end, my boy donated one of his 20 sided dice to the fix Took the opportunity to clean and grease all the mechanisms including the gear lever control centre operational1 point

-

Why are the starlet itb's in this thread? Because the the inlet manifold on the hilux sucks. Not power wise, it seems to work good. but it vibrates, cracks and the big plenum doesn't work with what im trying to do. stalls out easy and any kind of cam setup other than factory, even cam timing changes on stock cams makes it a whole lot worse. wont idle on all cylinders and stalls real easy. not ideal for 4wding itb's will solve the big plenum issue, also will be able to isolate the plenum from the engine with some short silicone joiners. to solve any vibration issues. So had those bellmouths in above picture from another project, recycling; extended them by welding some thick wall tube onto the bottom machined a taper into them to suit the 52mm throttles and slightly adjusted the bellmouth so has bit more of an elliptical shape. machined some of the excess off them. could have taken whole lot more off but was over it by this stage. will probably test them on the starlet before welding them into plenum1 point

-

Time for a smol update on the fiat. Have been chipping away with making patches and buying parts/paint stripping etc. Gave the mrs a wind up about getting motivated to finish it and she pushed me in to actually buying parts. Parts are in the country but the a holes at customs forgot to process the gst invoice so I'm back to bodywork.1 point

-

So i fitted the torque plate for the honing process. We only have torque plates for certain engine's. But lucky Ford xflow's are in formula Ford's so the boss saw the need to get one made. The torque plate allows you to simulate the tension of the cylinder being fitted to the block while honing. Some blocks move considerably from the head bolts being torqued up. This can distort the bore, sometimes up to 2 thou on various blocks. So it's like honing them in there assembled running state. I have heard stories of shops honing with hot coolant running through the water jackets to simulate total running conditions. All in the name of perfect ring seal you need a perfectly round and straight cylinder. We leave 4 thou of material to hone out as this gives us a good base to start achieving good rk rvk and there's another value aswell but I can't think of it right now. But we start off honing with a course stone which gives us a deep groves and removes material quickly. Once we've removed 3 thou we change stones to a smoother grit this removes the tops from the course stones while taking more material out. I'm also happy say I have removed all the bore wear marks after removing 2 thou of material. Now we move to a finer stone again same thing applies. Each different grade of stone removes material in different ways. Some stones will take more out of the bottom middle or top of the bore, so you have to measure the bore to make sure you're keeping it straight. The stones also react to load. Theres a round handle onto of the machine that applies load to the stones in the bore. If you wind to much load up it normally takes more material from the middle of the bore as there's no real strength there. Extra load can also create heat which will give you a false reading of size from the material expanding. Once we are at finish size we have what we call plateau stones. These are 800grit they don't really take much material out but smooth the tops off from the previous set of stones. Then we move to our cork stones. Which look nothing like cork. These are really good a removing left over honing material out of the cross hatch. We only give the bore a couple of strokes with these. Once a year we clean the machine out. It normally has about two 20 liter buckets fill of cast iron sludge sitting in the bottom of it. This machine runs 200 liters of honing fluid. Which is great as one of the jobs of the fluid is to keep the block cool as well as wash the honed material away from the honing head while honing. A drum of honing fluid isn't cheap at $2500 Then there's all the stones we burn through. So the honing process has one the highest consumables cost in the workshop per year. From start to finish it can take a hour to two hours to hone a block after a rebore. A deglaze or what we call a rering hone is normally about three quaters to a hour.1 point

-

1 point

-

1 point

-

1 point

This leaderboard is set to Auckland/GMT+12:00