Leaderboard

Popular Content

Showing content with the highest reputation on 04/14/19 in all areas

-

Did you ever see the engine run SOHC? A bit of info on this engine. It’s a 1930 JAP JTOR long stroke racing model of 1000cc. They were used in racing 3 wheel Morgan’s and Brough Superior motorcycles. These v twins are very rare these days and are worth a large amount of money. Lucky a place in the UK has reproduced some accurate castings for anyone mad enough to try make their own. I will be changing a few things with this one to try and get a bit more capacity and power out of it. Made a start on machining the drive side crankcase half. Bearing boss faced off to become the first reference surface Flipped over, mating surface faced and holes drilled. Now clamped down with spacer blocks to machine inner surface and bearing bore Inner features finished Next up timing side11 points

-

got the tail lights back in and the bumper on. the gaskets that go around the tail light holes were all fucked so i bought some closed cell neoprene strip from para rubber and stuck that on. it worked a treat and now the tail lights are all sealed up. 2019-04-14_03-38-29 by sheepers, on Flickr 2019-04-14_03-38-22 by sheepers, on Flickr also found this cool manufactures sticker/QC mark on the back of one of the door cards. 2019-04-14_03-38-13 by sheepers, on Flickr so yea the back end is starting to come together, got an issue with the brake lights not working properly but that will be something minor, im pretty sure they all worked before i pulled it to bits....... 2019-04-14_03-38-06 by sheepers, on Flickr11 points

-

This thing is broken also. have started to fix it. This is front suspension lower link, chassis end mount. its meant to be parallel to the chassis not bent down at the back. the force from the front link is mostly pulling straight forward. the mount has plently of strength to handle that, but it also pulls down slightly, and yeh bendy bendy this is the brace that runs up the inside of the chassis. weld held up fine but has tore a hole in the chassis, which is maybe 2-3mm thick. other side is fine as the braces run to the top of the chassis, this side was cut down as handbrake stuff was in the way. Managed to bend it back to where it needed to be, by putting the weight of the truck on the mount and using massive bit of pipe too leaver it back into place. Then plated the chassis and boxed in the mount, plus added another brace along the bottom side on both sides of the truck. wasn't much fun tig welding left handed and almost blind under there. but is stuck good. yep i changed that grease nipple so it doesn't get torn off One of the front lower links has been bent for awhile. plus had to replace the joints, with the proper johnny joints i brought ages ago ^ ^. Decided to remake all 3 links. New links are a size smaller pipe but are made from 4130. old ones are some cheese water pipe. so yeh new ones should be easily as strong and are lighter. drilled some speed holes in the retardedly overkill hand brake linkage, to make myself feel better about welding more stuff to the chassis. front uni of front driveshaft was smoked also. just looked old and corroded, rather than not being strong enough, so wacked in a new gen toyota joint. White is the old top link ^10 points

-

Have now seam sealed the front right inner wheel arch. Also got the car up on axle stands and off the trolley thing it's been on for the last 18 months and seam sealed the under side, no pics of that. Masked up the front left inner wheel arch and top coated it with Wurth 'Gravel throw and underbody protection'. I don't want to use the full fat bitumen based underseal as it's a prick to get off in the future if you ever need to - a lot of the underside of this car is still coated in it as the blaster couldn't remove it and I don't have the patience to lie on my back with a heat gun and scraper to get it off, so it can stay. This stuff seams to be favoured by those in the Porsche circles online so we will see how it goes (means I have Porsche parts on my car now right?) has the added benefit of coming in a rattle can, not sure if that means it won't last but it takes a bit of effort to scratch it once its dry.9 points

-

Proud new owner! Wanted this so much, I had it shipped up from chch. Unfortunately, previous owner ran into something, so I've been working away fixing that up. Lots and lots of other things to fix and improve. Little bits of bubbling paint really coming through, suspension is completely shot, and the 5 puck clutch makes for a pretty rough ride. Have been going over the entire engine bay hiding away many loose wires, securing power steer lines, and plugging firewall holes and the like. Here it is now, just over 2 years since the last thread update. The temporary Jolly chrome steel wheels will be for sale in the near future if anybody is interested. More to come soon! choice9 points

-

8 points

-

painted the boot. its not great tbh, got a couple of runs in it but its only a boot i suppose.... 2019-04-13_06-22-45 by sheepers, on Flickr 2019-04-13_06-22-53 by sheepers, on Flickr i also painted the dash. it was looking a bit shit and the sliver edging was all fucked so i had a go at masking the edges and using some chrome spray paint to bring it back to life. it came out super awesomeo! im really happy with it. the chrome isnt "chrome" as it was but its pretty close. sure looks way better than it did. im giving it a turbo win out of ten. 2019-04-13_06-22-37 by sheepers, on Flickr8 points

-

7 points

-

Did front wheel bearings, bought new front beam bearings, some other random stuff, new front calipers, greg has some new front brake hoses for me and so once i get some wheels and a new front spring pack (some of my leafs were broken) i can get it on the ground and rolling. A few things before its drive time but lists getting shorter Wheels, steering box, rear side windows, window seals, motor off @64valiant and be sweet for a drive i think i also bought a turbo legacy as a donor for a one-day engine swap dream project. Thw legacy was being sold by a mate for $750 with blown trans and 140,000km, seemed like a bargain and couldn't help it.7 points

-

Budget shelter nearly finished. We had to add 4 more ribs today to get the iron to sit better. Aesthetically its quite poor. Practicality, and budget wise it's very good.6 points

-

5 points

-

Work on the scamp has been on the back burner a little bit lately. However a chap in my Hot rod club was in need of some 318 engine parts, so I removed the factory 2 barrel intel manifold and rebuilt carb, I could’ve stopped there but I was at a loose end so I decided to pull a head. Looks like it’s had a pretty poor service history it’s fairly black and gunky inside nothing seems overly worn however Pistons have no markings to indicate being oversized It has a small ring ridge which it to be expected, but a quick vernier of the bore (albeit on the ring ridge) shows 3.89”, stock bore should be 3.91” so looks to be stock bore heads are standard open chamber heads. Factory sized valves 1.78” in 1.5” exh. Obviously until I get it on the engine stand and drop the pants off there maybe a different story but at this point it looks like a good base to start a build with.4 points

-

Have decided to use a water air intercooler this time , I'm going to mount it in the passenger side footwell/ up against the firewall where the heater was This means the intercooler pipes can be somewhat hidden. I'll run a pipe from the turbo under the rh guard thru the firewall . Out of the intercooler there will be a pipe thru the hole where the wiper motor was, straight into the carb hat This meant I had to shift the wiper motor to inside the car under the dash which is also a bonus cause it's very ugly. So I mucked around for ages getting the position right and made this thing. Shit update but it's progress at least...2 points

-

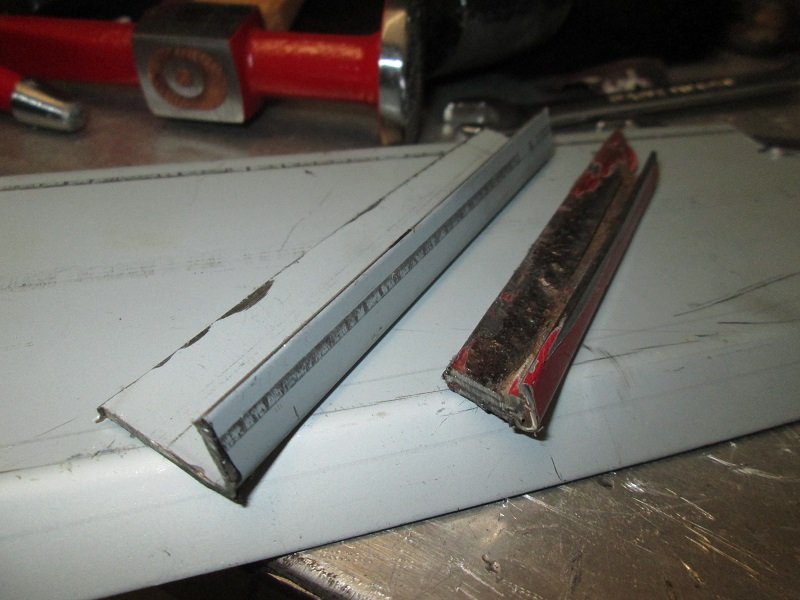

I think I brought one of those folders, then thew it into the steel skip at work. A nice 1.2m one would be awesome to own.2 points

-

I was just looking at your transmission cross member dilemma. Leave the crossmember where it is and work in reverse back to the body making a new body mount out of 3mm with a nice big reinforcing plate welded to the floor before you start. When it's done cut the forward and back bits of the mount off. Presto, crossmember stays in the right place and doesn't look so industrial. My 2 cents. *Edit* New sheet metal tool pics please especially folder.2 points

-

i bought a few things after xmas mate as up until then i was still bending steel over the edge of my bench and i wanted to see what i can do with half way decent tools...so bought a cheap bead roller ,folder and a 1"dimple die (didnt think i would use much else and not cheap).and a 12ton press.2 points

-

2 points

-

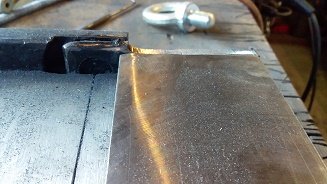

Well Xmas break was a bust, ended up finding more and more rust to fix. Not that I care, I knew it was an 80's Toyota from day one. Just means the goal posts are shifted as to when it will be legal. Hoping to have it sorted for Nats. Have been slowly chipping away at it, slowly filling a container will rusty bits of car. My shrinker / stretcher has been pretty useful, makes creating curved sections much easier. Anyway, some pics of some of the repairs. No point posting the photos of all repairs, as ain't no one got time for that. Still have a many repairs to do, just need to pull finger as paint drying outside is going to be a pain come winter. This update is basically just showing my rust repairs, which is all i've done on the car since last update. Making a new rain gutter section for bottom of A-pillar. Decent surface rust that got 2-3 layers deep in some areas. Replaced with single piece. Boot latch, seal traps water above the latch. Rusted out of my other car too, so out it came. Finished section, with boot frame pieces also cut. Doesn't look pretty, but it's all welded up now, and solid as fuck, so whatever works. Drivers side boot above tail light area, other side had similar repairs. Not much was left original, I just had to replace it a section at a time, to keep the original shape as best I could. Passenger side boot hinge area Drivers side boot hinge area, or at least what was left after removing the "structural" rubber seal. This took a bit of planning, as I had to make a section that didn't exist. Just imagine someone getting frustrated and spending hours on the stretcher/shrinker having not much luck. A lot of this area is 2-3 layers thick and attaches to supports underneath. I'll have to tidy the underside up later. Not many progress pics of this bit, no time for pics when frustrated. Transfer the curve on to paper, then put folded sections into stretcher/shrinker to curve to shape to form half the gutter. And just like that it was done, so simple.... Random repair found above tail light, viewed from boot floor.. Mayte, just tack some sheet on and fold it under, no one will ever see it. There is perhaps 5% of the original boot seal area left, it has all been cut out in sections and replaced. Was just going to replace the worst bits, but the further I got into it, the further I realised the whole lot was beyond a wire wheel and paint job. So that is some of the repairs, but certainly not all of them. Need to tidy up a lot of the welds ready for epoxy primer. So will be doing that over the next month, with the intention of having it all sealed up ready for filler and paint. In between repairs i'm doing my homework on what parts i'll need to get it back on the road. Bit of a boring update, but rust gonna rust.2 points

-

Been having tons of adventures in the wagon. Won a few more awards. Best 8 Cylinder at 4 and rotary jamboree And my favourite, the "What the ?" award from the Automania festival. Pretty much sums up the wagon You put a V8 in what??? So, back to my adventures and what not. I decided on the spark plug cover look I liked the most so I went with just the plain black covers. It worked quite well because I had heaps more people asking what the engine is, so I guess it fools them just enough without the V8 FOUR CAM 32 badge on it Before my trips I figured I would find a new brake pedal pad, I found it a hoot that it is a dodge truck part! Looking sweet, I will have to get another for the clutch at some stage, they are both the same pad So with the engine sorted and the brake pedal sussed I went for a cruise down to feilding for the 4 and rotary jamboree. I stayed at a sweet little B&B just outside of town. Got to Manfeild on Saturday for the track day, super excited because it is the only track in NZ that I haven't done a track day on, so I can tick every track in NZ off my bucket list now. Got out on track then on the first lap disaster stuck!!! The track had been used for field days the weekend before so it was super dirty, and the car in front of my chucked up a rock, smashing my windscreen!!! I drove the rest of the lap with my hazards on and my head out the window. When I got back to the pits I gave my friend Jared (A.K.A @JoKer) a ring and got him to bring me a spare windscreen over from Dannevirke. While he was making his way over I drove down to the local glass place and got them to swap the windscreen over. I got some funny looks cruising down the main road of feilding with a busted windscreen in a V8 Avenger, it was only about 1km from the track so I just drove with my head out the windows. Made it back to the track with the new windscreen just in time for the afternoon session. As a thank you, I took Jared for a cruise around the track. It was quite a blast My favourite picture of the wagon out on the track Out on the track I had a bit of a lean backfire off throttle so I pulled the car off the track early and set it up in the show and shine, After the show and shine I found the problem was the idle adjustment screws on the back right pair of throttle bodies had vibrated up so those throttle bodies weren't closing fully, fixed it in the car park. On the way back home I stopped in at Horopito, AKA Smash Palace to get me some wagon parts. They have a few Avengers there, 2 wagons and 4 or 5 saloons. Got me a good haul of parts, got some rear bumper brackets to replace the ones I had to borrow from the 75 Avenger when I swapped to the NOS Hillman bumper on the wagon. Got me a tow bar because there is nothing cooler than a V8 Avenger wagon towing stuff, am I right?? And also a pedal box for a friend, and a new door card. Got back home and gave the bumper brackets a good sand blast Then painted them with black zinc paint The next weekend I went off to @Ned house warming down in Taupo, So I figured I would camp out in the wagon on his front lawn. I am really digging the wagon for camping. The bed mode is really comfy, so I think I might do that more often rather than staying at hotels. On the way back up I meet up with the Hillman Humber club and we did a run out to a truck museum. Pretty good turn out. We had 3 Avengers there!! Then the weekend after that I had the Automania festival!! I entered my wagon in the indoor show. I figured I should actually get a photo with the bonnet down as 99% of the time it will have it's bonnet up, because V8! I went with a nice little in car display of some of my old Avenger sales brochures. I especially like the one on the back of the drivers seat because it has all the original prices hand written and a dealers stamp on the front, it must have been kept all these years by someone who was thinking of buying one, it's either 1979 or 1980 so it's from the exact era of my wagon, and even has the van pricing on it, and that you only needed 30% deposit, rather than the 60% deposit you needed for a normal car or wagon. I also entered my 1975 Avenger in the outdoor show. It was raining all day so my poor little Avenger Panther felt very unloved while it's younger brother sat warm and dry inside (Can you tell I have a favourite child at the moment?)2 points

-

So last Saturday i headed out to the v-dub shoppe to make a start on my engine. Paul was kind enough to work late and help me out. This is my engine and everything that is ment to go with it. inc the two boxes on the floor. I get all the bitch type jobs, clean this, clean that, and yeah clean that as well. so start with cleaning the crank. a little scotch in the cleaning tub and then we rinse it off with hot water. want to know why we use hot water? well hot water evaporates and doesn't leave any residue and wont rust. unlike cold water. now that that's done onto the casing. his has been machined out to fit the larger barrels and pistons to make it a 1776 so yeah lets crack it open see how many peaces of raw material i can find. oh hello. this stuff has gone everywhere. see if you can spot the peace tucked away here. that little peace of silver on the oil pick up is what you are looking for, well now that they are all cleaned up out side to wash these down with cold water. cause these are not steel and they wont rust away. hey presto we looking good now. 1st things 1st. dizzy gear in. i didn't snap a photo of this but here is one off the net. with that lubed up and in place the dizzy goes in over top. while i was putting that in Paul was putting the bearings in and making sure they lined up and marking them to make our life easier for when the crank slides in. i have also slid on 6 little rubber gaskets over the main bolts. bearing 1st. cam gear next, with some heat slid on over and sitting in place with its key way in next is distributor drive gear. my key way was a little lose, luckily we were in the right place and a few steps to the left was a container with a bunch of them in, found one that fitted better. some heat on this and on it went. bearings for the rods and on they go now. no photo of this stage my hands fill and doing other things but lets drop that on in in she goes and lined up Pauls pink dots and dropped the cam in as well.so far the only things out of the old engine are the gear peaces on the crank and the dizzy, even the dizzy drive was in a pile of other parts to the left of me that Paul just pulled out of old stuff. The rods and cam are from another purchase of parts i ended up with including the bearings and all the gaskets.Next Paul swears at his employees for leaving his gasket goo with out a lid and we put some goo on the casing and he drops the other side of the block on. finds some nuts that should come with the casing and he torques them up. its bloody handy having a store room the size he has, off i went find myself some lock nuts, re stock the draw in the engine build section. they get thrown at the engine and torqued up but to a smaller amount. sump on and well bake to the store room to find some dome nuts for the sump plug and the mesh for in side that, and a stud kit for the fuel pump, oil pump and a few other things. actually here is a photo of the kit, thanks google ahh while this was up side down we also dropped these in. which i learnt the other day is a duel pressure relief, vw casings come out duel and single, only early ones come out single. ended up watching a YouTube video of how it works and where they are. if you want to learn here is the video i watched it was a pretty good Saturday learning and building the new engine. last night i headed in and done some more work. removed all the head studs while Paul was on the phone and cleaned them up, he then came down and gave me some shit about how i didn't get the fly wheel and shims ready for him, few seconds later he had them, he worked out the end float and put some shims in allowing some small amount of thou. he was also trying to calculate out loud and man that shit was confusing as fuck to me. with that all sorted i now have the fly wheel and we are off to get skimmed and it has a really nasty lip where the rear main seal would usually sit so ill take that to geophfey and get him to take the lip off that. all in all shes been a great few days so far.2 points

-

2 points

-

2 points

-

wow having a mare. just some more paddock hacking. looks so tame in the vids. ask someone whos been in it.. and they will tell you how they wish they hadn't. @Stu@Snoozin2 points

-

@64valiant was selling a beetle and somehow i convinced the wife that we needed a joint project. @64valiant is chief adviser to ensure nothing too shit is done to it. Because he's a VW expert and truly entrenched in the VW scene and I'm a closet bogan this probably wont end well (EG, while i think this car is perfection, he's busy swallowing his own vomit.) (not mine, but i wish it was) Pretty keen to get this going ASAP, budget is essentially $500 a month until its going I'll put up some pics of our piece when i get home but happy to hear every bodies thoughts/advice/do you have a floor pan with live rego sitting around?1 point

-

Kia Ora A couple of people have asked where the build thread for my car is because they want to watch, there hasn't been much building - mainly de-building up to this stage but here goes. As part of my daily quest to be more like UJ about 6, 8 or 10 months back I was trawling trademe as I regularly do, seeing what's new.There was a fresh ad up for a Fintail Mercedes Sedan with the usual 3 shitty photos.This was right around the time I brought the v12 Jag motor discussed elsewhere, I mean one hobby is good but twos better right? This thing is also the reason progress on the V12 has stopped because I've been spending spare time swimming and getting the ball rolling on this. Anyway the ad as mentioned had 3 shitty photos on it, one of which was of a grainy pic of a not-so-Mercedes Falcon motor that it was fitted with. As a result of the Falcon motor the guy who owned it was getting all sorts of grief about it not having a Merc motor. Bugger that I thought, I'll go have a look. Long story short the guy wanted rid of it as it was a project he and his Son who's since left home had that never got anywhere and he just wanted the shed space, he didn't care what he got for it and couldn't be bothered dealing with the whinging people on trademe. So I bought it then and there. This is what it looked like when I got it, forever known as the OTP mobile. It's a 1965 Mercedes Benz 220Seb (W111 Chassis for those that care) in black, just like UJ, sort of. From what I understand 220 is the engine size (pretty obvious 2.2 litre), S is the bling model, b means its a fintail (the predecessor to this shape was also called a 220), and E, I believe, means it was a factory injected car but I'm probably wrong on that. It doesn't matter as it has the aforementioned Falcon 6 weighing the front down now. It appears to be complete, everything that is missing in the above photos is in the boot. When it was listed it was listed the guy said it was deregistered, a quick carjam report said that it wasn't deregistered, that it had simply lapsed and was due to deregister 2 weeks after I brought it, so I quickly put it back on hold after I picked it up. Live reg = Whoop. Props go to Sentra for tow car supply and Archetype for Storage.1 point

-

1 point

-

didnt even try it Pete. just fucked with it as soon as i seen it out of the box.1 point

-

for the cross member mate....pretty much the plan. as for the tools....eastwood 8" bead roller .. the folder was the cheapest i could find on trademe (and it was shit..had to modify it to make it bend a decent edge.) think i have some pics and the dimple die was made by one of our members as a side line1 point

-

Ok, so i've been trying to sell this car for a bit now (offered the chance to buy something else rare and awesome), but have had more time wasters with this car than any car i have sold previously. A couple of people that were "super keen" have even test driven the car, only to suddenly not be keen based on the KM (i've made the KM pretty clear), or because it's not "A real M" (also obvious from the start). I've been offered as low as 7K, and even a couple of offers in my ballpark that I have accepted, only to never hear from them again. So i'm seriously considering keeping the car for a longer period. That would mean finishing the list of things I want to do to the car (mostly cosmetic stuff), sorting the suspension (upgrading, either BC Golds or maybe Koni, and poly bushes) and a cert. On a whim i popped to Pick A Part today and got a good haul. Turns out they have a coupe there, so grabbed a few things I needed, including the boot carpet and plastic trim.... which means I can finally fuck off the boot install. I still forgot the ambient temp sensor, which was the whole reason i went >_< Next time.1 point

-

It was time to show some love and fit the mono shock. Could have made a better bracket Thinking of fitting this. any pro's and con's? Dont quite line up1 point

-

1 point

-

A bit more progress. I bought some Vitara seats from the wreckers, these are the same frame as the ones I put into my bus so I know they can sit pretty low once you start cutting and shutting. They are a bit more supportive than the Dyna seat, and they have the added benefit of being a pair, not a single. Banana for scale; I removed the bar that runs along the back of the seats, this allows the seats to recline into a far more comfortable position. It will go back in when the seats are installed and I know how much clearance it will need. I will need to split that engine cover lengthways and add another hinge and latch. This means I can still get into the rad space without removing the passenger seat. This shouldn't be a drama. I also checked the bump steer situation last weekend, first with the factory setup, then with the new arrangement. The new setup turned out pretty shit as my positioning of the new steering box did not put the tierod exactly in line with the factory setup. This was due to some geometry that I had to guess at a few weeks ago, but when I moved the box up 25mm this made a huge difference, it is now slightly better than the factory setup which is a big relief. The brakes look pretty new with minimal disc wear so that is good. About there is where things have stalled as my back went out pretty badly and I spent a couple of nights in hospital. I'm home now and itching to do stuff but I should probably take it easy for a while. I am going to have to get serious about losing my belly as I am sure that would make a huge difference to the situation. Fat old fuck that I am.1 point

-

Preaching to the choir here mate. It's transitioning back to the rust that's the killer.1 point

-

1 point

-

Is there a thread Barry can’t infect with his high spring attitude?1 point

-

Looks like i-force has pooped itself and all my images are gone. Bummer. Anyway, drove out of the garage for the first time in who knows how long to give it a bit of a rinse and rearrange the garage. Got a real ratrod vibe going on here. Out and about 1 by Thomas Addison, on Flickr Out and about 2 by Thomas Addison, on Flickr Pretty much done with stripping now, just finishing up the underside of the bonnet. This is the first thing I will paint, get some practice in with the paint gun on a big area that doesn't matter much. I've also been buying things. Found a single NOS fender mirror. These are usually astronomically priced for a pair, on the rare occasion they turn up at all. This one was surprisingly cheap and is super mint. There's one slight scuff on the side which I think will probably polish off completely. Nice. NOS mirror by Thomas Addison, on Flickr Got a cool gear knob to match my kitty cat headlights. Gear stick by Thomas Addison, on Flickr And lastly some 70s galant hubcaps. Really tidy and shiney. One has some curb scuffage, but no big deal. They came up on TM pretty cheap and I thought they make for another nice nanna spec wheel option. My current thinking is to have these, widen some steel wheels with the little centre caps and trim rings I have now and get a set of 14 inch japanese, period appropriate mags, as wide as poss without flaring the guards hubcaps by Thomas Addison, on Flickr1 point

-

1 point

-

1 point

-

1 point

-

i gave the center console a tidy up and a coat of paint. 2019-04-07_11-14-14 by sheepers, on Flickr then i climbed into the boot and started prepping it for paint. managed to get it ready without to much back pain so i decided to try and paint it. 2019-04-07_11-14-36 by sheepers, on Flickr came out really good so now i can put some seam sealer in the gaps and sand it all up ready for some colour.1 point

-

Pretty sure I flipped one throttle shaft so the two short ends where facing each other to make mine fit and had to custom fabricate the linkage. But what I really don't understand, how can you balance the carbs and not test drive?1 point

-

1 point

-

So I made the 24-1 distributor trigger, it works fine. I just cut all 29 teeth off the wheel using my barry lathe and then used a mill at uni to drill 23 holes and welded in 2.4 mm diameter tig rod as teeth. Instead of welding it onto the shaft I made the shaft slightly larger with some weld, turned it down so that it was a little bigger than the wheel and then blasted the wheel with heat and placed it over the shaft. Perfect interference shrink fit. I was having issues with the car cranking slow some times, not cranking at all other times, cranking moderately fast some times and starter motor smoking, and ignition interference while cranking. I pulled out the new starter motor and put in my original starter that I rebuilt the solenoid on and it cranks twice as fast, with no interference and uses half the power and doesn't smoke. Car starts nicely now - just need to play with the cranking advance and cranking fuel values to get them right again. Hopefully they will take the new starter back. It was interfering with my ignition from day one, and was what made me make the ecu controlled ignition system.1 point

-

have had people in the same situation who have added another mount in line with the gearbox mount to strengthen the offset crossmember, and others who have moved/ made new mounts in the tunnel so the crossmember can be straight the test I use is pretty basic, I grab the driveshaft or gearbox, if i can flex it up and down much, it needs sorting.1 point

-

1 point

-

Need to do updates more often so they're smaller! Put the tray on as I needed to see where I could run the fuel and brake lines. Also borrowed a pair of wheels off one of my parent's cars, to test the tire sizing. Bought a fuel filter and made a stainless steel bracket to hold it. Made some mounts for the rear bumper to bed brackets, as they were welded on before. Got out the LED tail lights that I've had for ages and made up some stainless brackets and polished them. Started running the brake line out of copper-nickel tube. Also got some 5/16" lines for the fuel lines. Made some stainless clamps to hold them all together and to the firewall and chassis. Made some bits for the column change linkage. Top middle piece mounts on the firewall around the column and has some little stoppers that make it so the gear stick needs to be pulled out to change from certain gears. Left bit is what goes over the stoppers and pivots with the gear stick to push the rod bit down, which then pushes the right piece down and change gear. Thought at first it would have to be some super complex system with cables and stuff but this way was actually pretty simple to make work. Then I needed to make up a indicator on the column to show which gear it was in. Drew on up in Solidworks and laser cut it out. The accelerator cable needed some modifying to work, it's wasn't quite long enough to reach the pedal, so made a new bracket that moved the housing closer to the throttle, which allowed for more cable out the pedal end. Then all it needed was a plate with a lot in it that bolted to the pedal to hold the little ball on the end. Have had some big train air horns for ages. Couldn't find anyway with enough space to fit them, as they were originally mounted together in a triangle shape. So pulled them apart, made some new brackets and bolted them up under the cab to the chassis. Need to just run some lines to them. Some boxes of stuff finally arrived from America. They included some front windscreen stainless trim, door panels and the surrounding trim. Might replace the door panels one day as they weren't as good as I thought they'd be for the "deluxe" spec ones. Also arrived were some wheels. 15x8 Artillery steel wheels with baby moons and beauty rings. Spent ages trying to figure out what colour to paint them, didn't really want to go red (what everyone does) or black (spent too much money on them for them to be hidden). Decided a bronze colour would look good and hopefully not too out of place. Then spent more time trying to find a nice bronze.1 point

-

1 point

-

1 point

-

Hello, Have skipped forward 756 steps and made a start on tarting up the wood interior pieces (wood interior, daaaaaaaamn). The original varnish has faded/cracked/gone yuck after 50+ years so I thought we can't have that. These photos are a bit out of whack but give a comparison: Before, as you can see - yuck. After 3 applications of paint stripper/scrapping parts came out like so: I took a trip to Bunnings to find some new varnish/stain. After 10 minutes staring at the shelf wondering 'do you get interior stain because it's for inside the car, or exterior stain because the car is outside in the sun...????' I walked out with a pot of Cabots interior stain and proceeded to throw 3 coats on things New vs OG: Ta da, photos are a bit weird, they make the pieces look like they're rough textured or has a bit of grit in the stain, but they don't they're smooth and look choice in person. Have a couple more pieces to do then that's done.1 point

This leaderboard is set to Auckland/GMT+12:00