Leaderboard

Popular Content

Showing content with the highest reputation on 11/02/18 in all areas

-

Picking this up in a week, essentially 1 owner; under 100km; plastic taken off door cards a year ago; fitted sheepskins have never been off; rear carpet always covered deceased owner owned a Toyota dealership, which religiously services it every 6 months with full log books. YFactory Air; steer; 7 seater. It’s a honey. Down in Melbourne so a 20 hour road trip coming up. Tried to buy a year ago but grandson selling it was a mess to deal with. This time around his uncle much more reasonable. Too mint to stuff around with too much. prefer the other style grille that i have; but a nice summer cruiser.10 points

-

Put a few centrepunches where the bearing presses into on the alloy housing7 points

-

I'm feeling left out cos I'm not spannering on a ride, I did however take the 19's off the support ute and put the 15's with a lot of sidewall back on in anticipation of the motu.7 points

-

and away it goes. i hope the new owner gets all he wants from the ownership. i learned some things while building this car. mainly that my heart wasn't in it, it had to many doors and i just wasn't in to it. I really struggled for motivation towards the end and thats SO not me. anywho, lessons learned. on to the coupe. 2018-11-02_07-48-39 by sheepers, on Flickr6 points

-

I saw my bike in the shed the other day, aint ridden it in like a month, i'm sure it will be fine/don't fail me Chinese Honda reliability!6 points

-

If you opened the motor, you'd probably find a few more bearings like that/ better not to know.5 points

-

Just ordered a new set of gloves. Planning to ride tomorrow till my tank runs out and get an idea on the distance to a tank. Pining hard. This time next week I’ll be over the other side of the Motu. Hopefully near Rere falls!4 points

-

4 points

-

so this thing has turned into a big job... went and pulled the galaxie outside and give the engine bay a full degrease and waterblast. then i wasn't happy with the finish paintwork on the firewall wheel tubs and pretty much everything. was coated was looks to be underbody sealer so looks super rough. so began sanding it off then i pulled it apart some more to help with the sanding process Then when i got sick of doing some sanding i stripped some stuff of the engine so now im at the point where ive fully stripped it and wanting the car ready for an event which is 4 weeks away. so heres to hoping not too much goes wrong right.... with plenty on the to do list4 points

-

Pulled scooter apart too check back brakes bearings spinning freely in the alloy housing whacked them out and backsides of them are open to absolutely no grease so purchased some new ones on the way home and some loctite 680, I hope that works oh and grabbed some of supercheaps finest lime green rattle can paint3 points

-

Just sing "Get ya motor running" to yourself on repeat, like I do.3 points

-

Waiting on parts and so there is a lot of things half done. Put the face back on, and swapped the big round FSO badge out for a black an old Fiat one, matty b over the pitted chromed plastic to murder it. Tidied up a lot of the wiring, all sorts of hacks and redundant add ons removed! Drivers side wiring wrapped in self amalgamating tape, much better looking than the factory packing tape stuff. Passenger side cant wrap it yet, but - moved the coil position and wiring tidied, - window washer pump relocated and old one it was cable tied to removed - fuel pump wiring and fuel plumbing still to do, but waiting on barbs and bits This was the old exhaust manifold on the secondaries side So i went and got the exhaust manifold from my old 1608 engine from the blue car that i spent a few power file belts on This is the port to the same gasket as above This is the head side gasket to ports took a few mm here and there on the inlet side of the head just to avoid any steps, but otherwise this 'big valve' head already matches up to the gaskets and inlet manifold really well. Should go much better.3 points

-

Need to do updates more often so they're smaller! Put the tray on as I needed to see where I could run the fuel and brake lines. Also borrowed a pair of wheels off one of my parent's cars, to test the tire sizing. Bought a fuel filter and made a stainless steel bracket to hold it. Made some mounts for the rear bumper to bed brackets, as they were welded on before. Got out the LED tail lights that I've had for ages and made up some stainless brackets and polished them. Started running the brake line out of copper-nickel tube. Also got some 5/16" lines for the fuel lines. Made some stainless clamps to hold them all together and to the firewall and chassis. Made some bits for the column change linkage. Top middle piece mounts on the firewall around the column and has some little stoppers that make it so the gear stick needs to be pulled out to change from certain gears. Left bit is what goes over the stoppers and pivots with the gear stick to push the rod bit down, which then pushes the right piece down and change gear. Thought at first it would have to be some super complex system with cables and stuff but this way was actually pretty simple to make work. Then I needed to make up a indicator on the column to show which gear it was in. Drew on up in Solidworks and laser cut it out. The accelerator cable needed some modifying to work, it's wasn't quite long enough to reach the pedal, so made a new bracket that moved the housing closer to the throttle, which allowed for more cable out the pedal end. Then all it needed was a plate with a lot in it that bolted to the pedal to hold the little ball on the end. Have had some big train air horns for ages. Couldn't find anyway with enough space to fit them, as they were originally mounted together in a triangle shape. So pulled them apart, made some new brackets and bolted them up under the cab to the chassis. Need to just run some lines to them. Some boxes of stuff finally arrived from America. They included some front windscreen stainless trim, door panels and the surrounding trim. Might replace the door panels one day as they weren't as good as I thought they'd be for the "deluxe" spec ones. Also arrived were some wheels. 15x8 Artillery steel wheels with baby moons and beauty rings. Spent ages trying to figure out what colour to paint them, didn't really want to go red (what everyone does) or black (spent too much money on them for them to be hidden). Decided a bronze colour would look good and hopefully not too out of place. Then spent more time trying to find a nice bronze.3 points

-

2 points

-

2 points

-

I wonder if I get AA plus then sabotage my bike at the end of the ride it'll get shipped home for free? Only kidding, I'm way too mean to buy AA plus.2 points

-

I've been doing a bit more work on my closed loop ignition computer thingy. I've got all of the code working but still fine tuning things like how long each set of tests needs to run for. I've found that it works really well at say 3000rpm and 80kph, but then higher rpm than this it gets confused, lower rpm than this it gets confused. At about the 80kph region with my ignition map set to be 10 degrees across the board. On flat road it stabilizes at 40something degrees advance. Cool! But then at lower or higher rpm, it keeps wanting to pull the timing back even from 10 degrees. I think what happens is that because I'm so far from MBT, adding 3 degrees extra timing gives it a reasonable torque bump so the vehicle speed overshoots, then goes into fuel cut which I've told it to cancel the test and restart if this happens. I need to spend a bit more time fine tuning how long each test runs for though, or allow more of a delay before collecting samples. Looking at the fuel consumption vs ignition angle you can see that theres a bit of a delay until it shows the effects of the change (If red line goes up, thats less fuel) Another problem is that I am only interpolating the results back to the 4 cells in the table that its taking the ignition timing from. But what I really need to do is "waterfall" the results so that for example if you are at mid load 3000rpm. It doesnt make sense that if you back off the throttle you should ever go down to less timing than that. And same with RPM increasing at same load, you are only ever going to be needing more timing. So I'll make it so that every time it adds a new successful result it will spread that to any lower load cells and higher rpm cells if there isnt already a higher value there. I think this will cut down a lot of my false results. None the less I'm pretty chuffed that its showing *some* amount of sensible results and there seems to be clear ways in which it can be improved from here to work better under more circumstances. This is the ignition table that it has generated after about 1/2 an hour of plodding around on the motorway. (Values in table are degrees ignition * 10 )2 points

-

Soldered trigger wire back on, now back to hooning, need another good ride under its belt before next weekend.2 points

-

reassemmbled it and got the headlight on close enough, Took it for a blat up the road and it cut out on the way back. Don't know if it flooded itself or something fucky is going on but its now tomorrows problem2 points

-

2 points

-

2 points

-

What have I done recently.... Fuck all! my mate scored a Ute so we stripped it out and as Payment for doing it and storing it at my place he gave me the diff. It’s an H165 which is a bit bigger and gruntier than the standard H145 in it now. Ill get around to swapping it in at some point. It’s not a straight bolt in affair but achievable in a day with some wee mods. its got a new 2in exhaust all the way through with 1 reasonably new muffler that was kicking around, made a decent difference to performance, has a great rasp to it and dosent hit the ground or body! It’s like, slightly too loud but acceptable. I farmed it out to a mate at pitstop cause I fucking HATE exhausts. i put new carb kits in it. I put it on the dyno and made 64hp at the wheels, I thought it would be closer to 80 but no.. power to weight is a wonderful thing! theres a track day this weekend so I whipped the discs off and got them skimmed, kitted the calipers and painted, new pads. Brakes were getting very manual. i finally got that proper wheel alignment done, booked at another local shop and they rang to say nay, and sent me to Tony’s tire service on Blenheim Rd. They have some fancy Hunter machine that can cope with low old cars with small profile tyres. It’s great now! Haven’t driven it much since, it was pissing down when I picked it up so couldn’t cane it properly.2 points

-

so i decided that i would keep up with the normal oldschool tradition and pull my car apart once shes all legal. so the other issue this car had was the carb setup it had some unknown brand cheap carb that you couldn't get it to run mint on. so the plan was to put a four barrel manifold on to help it breathe as it only had a two barrel one currently. but the plan was to do that after the cooling system was done. but when i removed the waterpump it had a pipe that joints the waterpump and manifold well that pipe broke due to being rusty and old so that would've needed to be fixed but figured it would be better just to put a 4 barrel manifold while i was at it seen as it isn't much more work right plus it would've ended up pulling the same stuff off twice. plus it had a oil leak from the sump which required motor out anyway and other areas which made the nice clean rebuilt trans not so clean. oh and how the engine bay and motor didn't look so great so now oh while im there i may as well do that as its not much more work has involved itself into this car haha.2 points

-

It would be fair to say that I'm a tad ocd when it comes to start up and idling. I was forever trying to get it better. Enough that I notice when factory setups seem rough. So if I had set that up wrong, which or seems I might have, then I'm not only a bit embarrassed but also annoyed with myself for the amount of time id spent chasing the perfect idle. Oh well.. Worse things in life.. First World tuning problems.....1 point

-

Ammo tins are for pansies, mortar tins are where its at. It does need a c notch to clear the exhaust. Or I'll be a pansy and use a ammo tin1 point

-

Woo, I've got one of them USB things, might look at installing it too. Can run my USB fan .....1 point

-

Just need to wire in usb plug and fit a relay to run it then we in business1 point

-

I got a bit carried away yesterday and bought these. A set of 5 in 16x8. They're made in Japan, but the only maker's mark I can see is "4wd Engineering Service". They need a tidy up, but once I sell the tyres they should be free. Also, free plug for Youi insurance. 1 hour after submitting a claim form the car was booked to be assessed. My excess was also waived without needing to confirm fault with the other party or anything else. Bloody impressed for what's meant to be cut price insurance. Edit: this is the tidiest one.1 point

-

Wheels take a beating so if you want it to last a long time you would use 2k urethane. Then it’s easy to keep them in tip top shape, you can wax, clay bar, polish etc real easy. Clear or single stage 2 part is up to you, single stage 2 part urethane looks kinda weird in some colours/applications,base and clear would be the go IMO. Its basically choose the paint technology that suits the durability you want. Solvent cured paint if you want it to last fuck all, modern 2 part paint for everything else.1 point

-

1 point

-

1 point

-

Loud Pipes Look Rad Fuck yeah im fizzing over the thought that this time next week ill be enjoying cold ones over a bbq in Papamoa after a afternoon of riding around Tauranga checking out the sights and scenes1 point

-

1 point

-

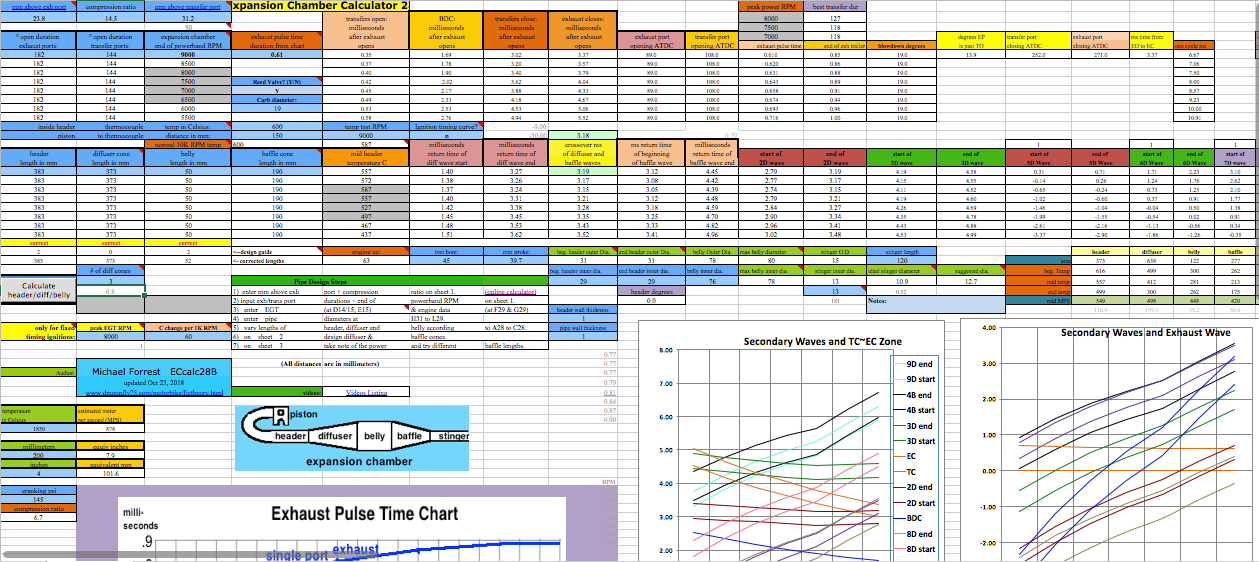

My brand new kickstart lever turned up from the Netherlands. It was a very reasonable price (16 euro) but the shipping was not! (I don't want to mention the shipping cost). Nevertheless, it's super nice to be able to start this without going for a run.... I got itchy toes and wanted to experiment with the pipe some more, so I spent waaaay to long mucking around with this expensive spreadsheet. The calculations gave me quite a long chamber length and kept the standard header length... But man it was long. I had to pull the muffler up on a 45° angle to avoid a tripping hazard for pedestrians. Took it for a few hoons like that, found no real benefit to performance and decided I didn't like it, so I chopped the whole thing up again and put it back to the old setup: Good way to waste a couple of days . Hopefully my sprockets turn up from Yambits this week. I'm keen to see how far I can gear it up!1 point

-

1 point

-

I got this diff from Dan for less than labeled after deciding the hilux diff was too heavy, the caliper conversion situation, handbrake creation and it wasn’t lsd. this is! easily available, inboard handbrake and disc brake already. The GT2871r I had was pronounced dead due to cost of repair. Then a mate popped up with this, got it for a song and will be a nice wee upgrade whizzer. Heres another escort with CA. The angled engine bugs me, it’s factory but I can’t handle it so I’m going to upright mine. I’ll have to change mounts anyway, tweak the shifter to suit. I have a brand new genuine oil pump as well. If she blows up we’ll try again. its well documented these days how to do this head drain mod so will do that. Today I sorted out lots of nuts/bolts/screws and put them into an organiser case for the first time in my life, reorganised the boxes, tore the front and rear ends out, front off, bumper off ready for the spit this week. Had a scotch with the dog while sitting in the back seat. She was more interested in the reflections1 point

-

for those wondering what became of the old Tranny.............. My brother bought it, and took it to Tauranga. He has fixed the brakes, and a few other bits and pieces, given it a good clean etc. and got it running and driving well. As I type it is now on its way to Avalon TV Studios in Wellington for its first job, starring in a NZ film about gang life in the 60's and 70's, as a Police van!1 point

-

The ecu has an injector test mode so you can find the dead time without too much hassle anyway1 point

-

after waiting for the steel to be cut on the laser (so much nicer than old mate with a cutting disk on the grinder) they were finally done and i could start forming them and welding them up to the chassis. now im no fancy engineer but all i am trying to achive is alittle more stiffness and to try keep the chance of cracking to minimum, so at every mounting point or where the rails change direction i fishplated. im also trying to follow the hobby car manual to keep inline with the lvvta reqs.1 point

-

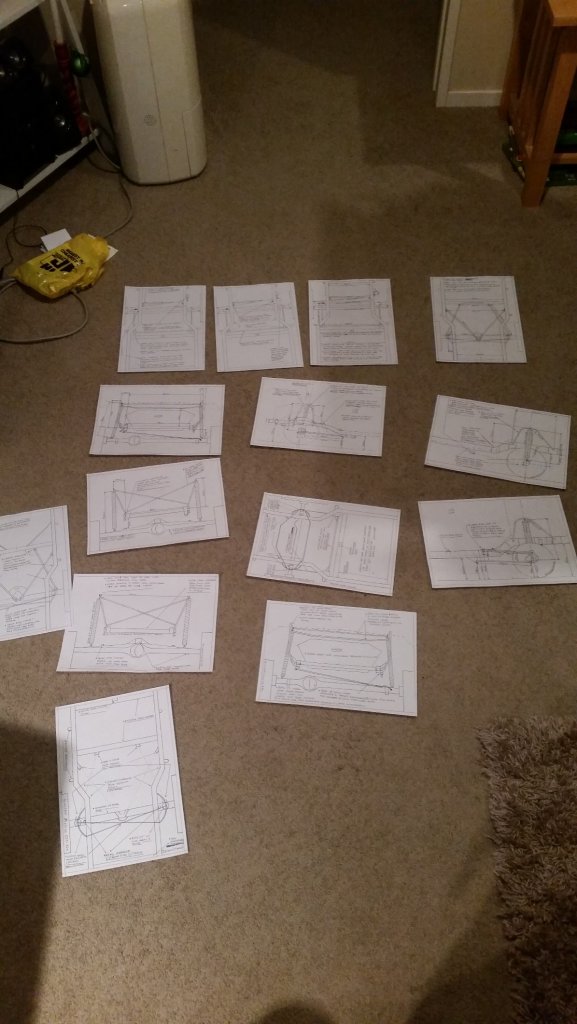

so after making it run well i got used to the power and was super unhappy with the factory leaf set up, twitchy steering, axle tramp, no flex, ride harshness and general truck trying to kill driver. decided it needs coil overs... then the baja videos came.. i spent about 2 months measuring, drawing, reading and thinking about how i was going to undertake this, alot of info regarding building anything to do with speed and offroad is kept under wraps so it takes alot of time to get through whats on forums etc..1 point

-

My parents came back from America and brought back a bunch of parts for me. Nothing really too exciting, just some headlight parts, steering column rebuild bits and various rubbers that I needed. The slightly exciting parts here were door arm rests and exterior door handles. There is some cool bits coming in a container soon though! They also picked up some NOS optional fog lights for a Chevy truck which are cool. The ignition switch that I got didn't work in the original bracket that fits into the dash, so tried to come up with ideas on where to put it. Came up with this, has the ignition switch and light, rpm gauge, wiper switch and oil pressure light or something. Would probably cover it in black leather to match the door cards, don't know how I feel about it though, sorta looks a bit bulky. Might revisit it later again once the inside is painted. Also needed somewhere to mount the airbag controller. Made it hinge down under the panel and pivot up when it's needed, which worked alright. Other option is to modify the original ash tray and put it in there, which I would prefer but requires more work and cutting up the dash panel. Dropped the engine back in and regretfully put the old rusty jag wheels back on to roll it off the hoist. Bought some Durapox clearcoat with flattener in it awhile ago and have tried it on quite a few different parts with varying outcomes. Unsure what's going wrong but it doesn't seem to flatten off if it's put on more than just a light dusting coat, just stays glossy if too much is put on, but it's sorta patchy/rough if it's too light. Have gotten these bits good enough, but seems like it's going to be a real pain to try and get the whole truck consistent. Had an attempt at patina-ing the grill guard. Doesn't look too bad I think, will have to see once the grill and guards are back on though. As I was having problems with the clearcoat, I did some research and turns out the suction feed gun I was using had a 1.8mm tip which is a bit big for painting/clearing, more used for primer. So we went out and purchased a new decent gravity feed spray gun. Took the rattle can primer off the firewall to put some epoxy primer on. Epoxied. High build primered, and then filled all the spot welds, little dents and welded holes that needed doing. Then spent ages sanding! Once it was smooth enough I remasked it and applied some paint with the new gun, which is quite a bit better. Isn't perfect, but good enough for a firewall. Made up some plates that bolted to the upper door hinge mount on the cab and then welded a long piece of RHS between them. Then used some tie-downs wrapped around the hoist and flipped the cab on it's back, which sits on some inner tyre tubes.1 point

-

Gave the exhaust a paint with some high temp paint and then tried to assemble it all with out getting too many scratches, wasn't too bad. Bought some new braided rear brake hoses from Australia. The steering rack rebuild kit I got from England was the wrong one so just left the current seals as is and hope they are alright. Sanded it all back and gave it a coat of paint and assembled it back together. Made a new filler tube for the fuel tank and added a drain plug. Since it then needed painting again I sent it off to get powder coated instead. Cut some rubber up for the mounting straps. Just had enough rubber left over for the fuel pump seal. Pulled the engine out and gave it a good clean up. Still isn't the best as some of the aluminium parts are a bit oxidized. Whilst I cleaning the engine I got sick of looking at the hideous standard headers, and ages ago I drew up some exhaust flanges and cut them from 10mm mild steel. So I'm going to try and make some headers with the very little space available. There's heaps of room upwards so maybe try and do some high-rise ones. Started by making some ob-round to round transitions by bumping them on a pressbrake from two pieces. Worked really well, they were quite accurate to size. Need to put the engine back in, cab back on and fit the inner guards so I can build some jigs.1 point

-

Painted the diff, came up pretty good considering how rusty it was around the hubs. First time changing brake shoes, thought it would be harder than it was. Hardest part was just trying to pull the springs into the slots, but got there in the end. Bolted almost everything back into the rear end. Finally cut down the 4-link bolts that have been annoying me for ages as they had about an inch of extra thread. My Dad (www.acecustoms.co.nz) makes these diff head covers to suit Holden/Falcon diffs as well as others. So I grabbed one, trimmed some material off the fins (so it didn't hit the fuel tank crossmember), rumbled it all day at work and then polished the fins. Also made another brake hose bracket, as the previous one didn't work with this cover.1 point

-

Made some mounts for the gauges. Also made a mount to add some strength between the pedal box and dash. The wiper motor was just dangling around with the single mount so made another that connects it down to the bottom of the dash. Once they were made there wasn't much else that needs access from behind the dash so I welded the dash in. This is the second heater mount I made, the other one didn't look right as it didn't go up as high and wasn't the correct angle. Attached it with some rivnuts on the original firewall stiffeners or whatever they are. Found a high stop light in my pile of parts so decided to make up a bracket to sit on the seat frame. Gave all the dash parts, cowl vent and handbrake a sandblast and rustkill ready to paint. Painted with 2k gloss black. Made up a new brake line mount on the diff because the other one was fairly close to the exhaust. Have ordered a new line and fitting for it. Finished all the lines for the airbags. Here's a video of them working, the back still goes up very quick but that should hopefully slow down once there's more parts/fuel.1 point

-

Went and bought a bunch of things to finish of the air bag system. Got a couple of water traps between the compressor and tank now. There's already a decent amount of moisture in them from a few fills as you can see. Bought a pressure gauge as well, just to check on what it's doing occasionally. Trying to get all the correct fittings for everything to work was a mission haha. The 3/8" line coming off the tee is for the huge air horns that I have, it's sooooo loud! Waiting on the laser cutter at work to be fixed so I can cut out some brackets to hold all the lines in place. Undersealed the running boards and the radiator panel. Split apart the grill bars that were all the riveted together so I could sandblast and paint the backside of them. No progress pics but here's some of them done. Painted the back ones cream underneath because they were originally that colour on top but they have some blue overspray on them. It should mostly clean off with a scotchbrite, as that needs doing all over the body panels before it gets clearcoated anyway. Started to assemble the front grill/radiator panels. All went together well apart from the fastener sets I got from America not having the correct amount or just missing things all together. As you can see in the above pics I also assembled the park lights, I had new lenses, bulb sockets, gaskets and chrome surrounds but no new housings. The original ones looked pretty bad before I pulled them all apart and gave them a sandblast, but cleaned up like new with some silver zinc paint. The new bulb sockets I bought were double contact ones to run park lights and indicators on a dual filament bulb, but I had some orange/amber LED's laying around that fitted, so may use them and just have parklights in the headlight housing and have these just as indicators.1 point

-

1 point

-

1 point

-

I got this golf lip for it, the valence I used had already had one on so I left the holes in when I painted it for this reason. it sits high, not hideous but I will lower it and see. That will change the angle too. i scrubbed clean and painted the sump yesterday1 point

-

I took some quick shots this morning before work just in case anyone crashed into it1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpeg.384ff72c8d2b0ee0d34a7bdedb55bdcf.jpeg)

.thumb.jpg.c4d243a5c47b1f788a0e4136cd079a06.jpg)