Leaderboard

Popular Content

Showing content with the highest reputation on 09/13/18 in all areas

-

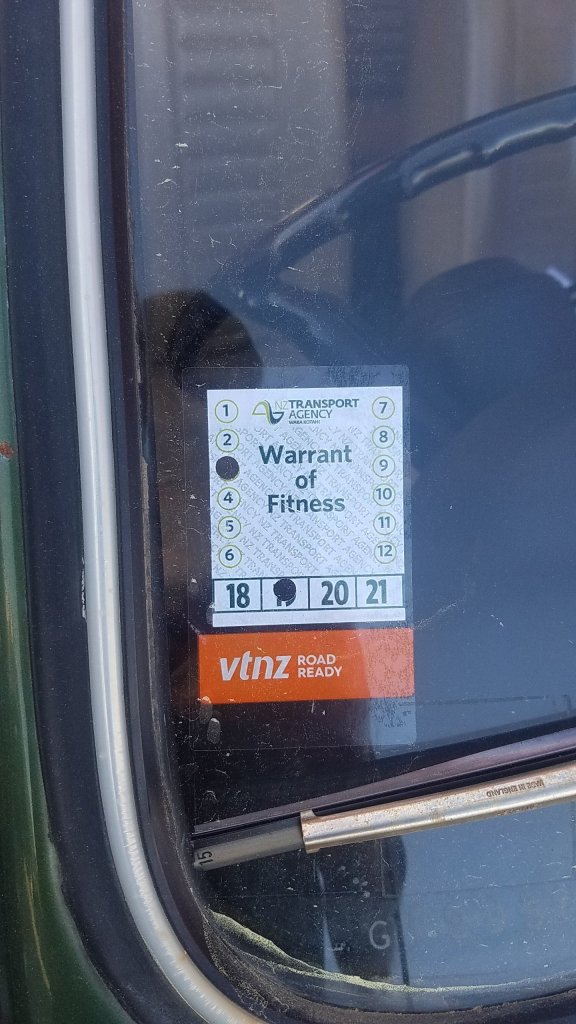

Tackled some wof issues.. :adjust steering box :headlight to operate :right rear indicator to operate :front brake imbalance 28% mrs picked up a headlight from auckland, an oem lucas fitment. Sorted. pulled the bulb of the indicator out and blew the dust out..sorted. bled the front brakes, everything else seems fine, if not then chuck in new pads. Sorted. there is no adjustment bolt of these steering boxes. So I Barry'd over the 5 different manuals I have for this and saw that the adjustment is via 2 internal Springs pushing on a thrust cap.. so I just chucked a couple of washers under the spring to take up some of the freeplay.. sorted. So this just happened, fresh as.. While at vtnz I heard of 3 different hillman hunter stories.13 points

-

Configured the turn signals and headlights on the dash Made a small sub loom that connects up to the old instrument cluster wiring. The old dash only had one turn signal indicator so that made the wiring for that easy, the high beams were also easy. I had to do a little logic in the dash to get the low beam working the way I wanted it to, for the low beam I had to use the panel illumination which meant the little low beam light would stay on when I went to high beams. The dash lets you use If.. Then.. Else statments so I set it to use "If Low Beam = 12V and High Beam = 0V then turn on the light If else turn off the light" and for the high beam I just said "If High Beam = 12V then on Else off" so that way when there is 12V to the low beams then the low beam indicator will come on, but if there is 12V to both high and low beam then it will turn off the low beam light and turn on the high beam light. The dash really powerful like that. You can use conditional statements for any of the alarms or warning lights. Got some temporary wheels so I can get it on the trailer to get it dyno'd etc. I am still waiting on the proper wheels to arrive from Aussie. Hopefully they arrive soon. These are on the front with a 30mm spacer And the back, again with a 30mm spacer And it sitting down on the ground. I am still waiting on another set of spacers for the front wheels so I still have the front sitting on the dollies we made. Finished off the radiator, popped the trumpets back on, and added the sealing strip around the top of the air cleaner. It's starting to look real cool now. Just enough room for the radiator hoses. Installed the bonnet pins. They are a little higher up than I would have liked but I didn't want to cut in to the supports anymore than I already have in the middle of the bonnet. My other Avenger had a fibreglass bonnet so it's a bit easier to place the pins where you want them. I have to mould for the bonnet so I might make a fibreglass one further down the track, or maybe paint the bonnet pins body colour.12 points

-

Dishwasher packed up again yesterday. Same fault, different drawer. Home sick so had a look. Yep, same heater element relay had burnt off same pin. Must be a common fault given both mine have done it... De-soldered and pulled relay, couldn't be arsed getting another relay from eBay so thought I'd try repairing it... Drilled out board where the short pin was to make room for my bodge fix... And soldered copper wire to very short stub on relay, fed thru hole and re-soldered other pins to board... Laid wire along track and soldered at couple of points... Seems to have worked, just done a cycle ok. Might buy me a few more months...7 points

-

5 points

-

I did have a thread for this, but it didn't get worked on for several years, and I think it has gone. So, start again. (Picture here of Datsun when I first got it if I can find one) I have/had (depending how you look at it) a 1985 Datsun 720 4wd. It was gutless, it had rust, so it was a Datsun (not a Nissan haha). I thought I would pull it apart for some rust repairs and paint, that was (too) many years ago, it snowballed, I ended up disassembling the suspension, driveline, painting a lot of things, modifying the gearbox to accept an RB, bla bla bla. Then this year, I had been chipping away at it, I had finished study and finally had a decent job. And one day as I was doing something I looked at it and decided I wasn't going to be happy with it when it was done if I continued down the path I was on. I couldn't add too much power or things would explode. I couldn't get aftermarket parts to improve things like ride height and driveability (not easily or cheaply anyway). So I thought, "stuff it", and decided to just do what I wanted in the first place, and had always said I wouldn't do because of cost essentially, but yeah, now I'm just going to be irresponsible for a bit and throw money at this thing until it runs and drives and I am happy with it.. So the basic equation is: GQ/Y60 Patrol chassis and suspension, diffs etc. 4" suspension lift and all the goodies that go with that. + RD28 gearbox from RD28 factory patrol. + RB25DET from your friendly neighbourhood Ceffydrift/Skidline. + Datsun 720 King Cab body, with factory body mount points, adapt the chassis to suit. + 33x12.5 R15 tyres on -22 offset 15x8 steel wheels. + Flat deck because practicality (I do want to use this thing once it is done)/ease of adaptation to Patrol chassis, and adaptation to toolboxes etc. = Profit??? /more likely major losses. But profit in happiness. Have done some work so far, but a lot of time/money has gone into setting up my shed to make this project as easy/efficient as possible. I modified the roof in the shed: (Ignore thee strange writing on the walls, it's an old farm shed that has slowly been modified to be my garage, there are lots of .22 sized holes in the walls, and there were gas lines in the ground when we dug it out to put in the floor) So I could install a hoist, which has multiple uses: Lift it up to put it on a dolly, damn these things weigh a whole lot. On a dolly next to the gearbox from the Datsun with an RB25 front housing swapped onto it. Slight size difference. Patrol chassis in place. RD28 gearbox. Unfortunately this chassis originally had a TD42 (which it didn't come with, but there was no way I could use anyway as it was waaaaaaaaay too big), so the driveshafts don't work, but will have a look to see if Beattys Drivelines have any listings or if I can source replacement entire driveshafts to suit. Nissan Lego! With the body in about the only place it will go, i.e. engine will fit behind radiator support with radiator under the panel, gearstick in a useable position, etc. Will likely need to cut and box the firewall/tunnel. Had to cut out this bit as well as some of the seat support to let the transfer case shifter come through. With that cut out the shifter comes through the factory shifter hole, bit further back than normal, but still very useable, and with a slight tweak to the actual shifter the transfer case shifter will work fine and not rub on the passenger seat. The picture above is with the shifter in 4th so that is as close as it gets/have checked it in all gears. Currently tidying the rear diff: Painted in POR15, will get new rotors and rebuilt calipers shortly. Then will go back in once I buy the last pieces of the rear suspension lift, which will give me enough time to tidy/paint the rear of the chassis. Has an LSD which seems to be in good condition, which will do until it is on the road and then I can think about an air locker. Went to Auckland the other day, got some tyres from @Stu, bloody nice guy, nice to meet you in real life after all these years of seeing you on forums. Sharp price too. Pictured here with my parents flash new couch and a whole bunch of new free diving gear, was an expensive day all up haha. (Please excuse the twist in the tie down, I know, I'm embarrassed for me too) If you are thinking: "Gee, that looks like a fairly low offset wheel, and you are already putting them on a chassis that was designed for a significantly wider than the body than what is going back on it, are they going to fit?" Then the answer is "Yes?" Gonna have to make/buy (I don't know of any 200mm ish wide you can buy?) some fairrrrrrlllllllyyyy hectic flares, but I really don't want to reduce the offset, so that is what I am sticking with until such a time that I may be forced to do otherwise. They should be fine this way, will just be a case of trimming the sheet metal to suit. Look, honestly, if this were an exercise completely in practicality, then I would have failed. But mostly it's an exercise in "I do what I want", then deal with the fallout. So I call that a win! I get my new welder this week (HF TIG, MIG, Arc w/ spool gun) so looking forward to having a play with that, and potentially making a start on the design for the chassis to body mounts/posts, will make up something up then get them ok'ed by my local certifier and welded up fully by a mate I hope, my welds aren't up to crucial parts like this and I feel like there are better places to practice on. At the moment it is sitting on the hoist with the chassis on axle stands. I will make a discussion thread shortly and link to it at the top of this post, let me know your thoughts, constructive criticisms etc. I will try to keep this updated, I am good at taking photos of stuff usually as I do it, just terrible at actually putting those pictures up. Cheers, Hayden.4 points

-

4 points

-

I need recommendations for tyres. The current ones are OLD Ching Beys or something. I'd like a sportier option, like what's on @Horse25's RD50. It's got 2.50 -17's at the mo and I'm wondering whether a 3" / 90 would fit. Also removed the wheels to check the brake shoes. They're pretty glossy and old! I've ordered a new set from @Raizer. Something tells me the rear brake lever isn't in the right place... It sits really high and quite far out to the right: Might need a gas torch to get it into the right place. Current state of affairs: It's pretty amazing how much you can do on a bike with minimal effort. Last night I removed the engine to check a couple of things. This required removing ONE BOLT (foot pegs were already off) and undoing 5 wires. I'd been trying to avoid removing the engine because it seemed like a hard job .4 points

-

That ad is soooo unrealistic A female wof inspector at vtnz!4 points

-

got motivated (wifes friends were over) went to the shed and started welding my exhaust ran out of gas.....3 points

-

Entry form is in the works and will be incoming shortly thanks to @johnnyfive and the wicked help of @- i5oogt -. EVERY PERSON that is coming needs to fill it out. Regardless of rider or support crew. Last year John took details on the day, but it took a bit of time and this is a surefire way of crossing the i's and dotting the t's incase the unlikely happens. Chur bruddas. Better go put my bike together aye.3 points

-

very cool The trick with dirty aluminium is to clean it as well as possible then do your welds twice (seriously!) Do the weld as best you can- it will be spotted with impurities and shit bubbling out of the material. Grind all of that dirty material off and then do the weld again over the top. Worked for me with a used LS sump3 points

-

3 points

-

I moved the operation inside tonight and started to put the dash back together. I’ve got a spare for parts but will be using the sweet chrome rimmed dials. It’s got a v8 calibrated rev counter. I stated polishing the varnish which I originally applied more than 3 years ago now and it is looking sweet. I love the dash one these cars - kind of super marine spitfire mixed with your grandmas burr walnut hall table.3 points

-

Welded in brace with all the middle cut out of it. Worth the effort.3 points

-

Hey just wondering if my chev would pass a warrant? Vtnz said yes but im not sure. Here's a pic for reference3 points

-

These were taken many years ago in the tunnel at the bottom of Ngauranga gorge Shits changed there abit but havn't been there a while. can only assume all the graffiti is long gone.2 points

-

2 points

-

Now I'm having a panic attack! I need my overnight parts from Gizzy!2 points

-

It's on my to do list. I want to make it as sleeper as possible. I might have to wait until I get the rest of the outside repainted though. Thanks. I am rushing to get it ready for a mopar show that I am driving to in the South Island in October. I still have about a month to finish it, so I'm looking pretty good. The wheel are the only thing that I am waiting on now.2 points

-

2 points

-

Rear screen is out and it’s good news, no significant rust, just a bunch of scale, it’s being cleaned up now (and any Pinholes being sorted) and then the roof can be painted and the screen refitted. Hanging out to have this home again so I can work on it. In other news The car sounds like it has a collapsed lifter, so today I ordered a comp cam/lifter/double row timing chain/valve spring kit from Summit racing. I hadn’t planned on it but if I was going to go to the effort of replacing lifters I may as well upgrade stuff.2 points

-

2 points

-

Big milestone. Fired the engine up for the first time. A few issues. The biggest problem is that the TPS doesn't work, The shaft on the throttle bodies spins the opposite way to the standard 1UZ TPS. Need to do some research to figure out what TPS I can run. In other news. Got the gearbox boot and gear knob. Tried this one but it was a little high for my liking. Swapped it out for a smaller knob which feels much better (Ladies!! See, a bigger knob doesn't always feel better) It also has the correct H pattern on the top which is cool because it is different to the 5 speed sierra gearbox in my 75 Avenger and the old standard Hillman 4 speeds, they both have reverse next to first instead of below 5th, so I'm sure I will forget where reverse is on this one if I didn't have the H pattern there. Also got the dash up and going. It still has the protective screen protector on it so it looks a bit fuzzy. I will take that off once it is all mounted in the car.2 points

-

2 points

-

I wanted something to put on the wall in a blank spot, paintings are pretty pricey so thought a spitfire skeleton might look cool. I bought a wee balsa wood kit and did this... Cheap and fills the hole2 points

-

So a while ago( back in April) @M Night Shamalayan chucked up a for sale post for this delightful 72 Hunter.. turns out its a Super, with high back reclining seats and lots of chrome trim. I had a 69 Hunter as my first car, which I promptly rolled into a ditch 3 months later.. Ive wanted another pretty much ever since.. dont ask why cos I have no idea So as soon as I saw this post I jumped at it, with the car being in Wellington, Me living in Auckland, and potentially moving to Invercargill, I asked Luke if he could "hold on to it for a few weeks".. "sure" he said... well shit, I bought a house down south and we had a move in date... It just happened to happen the week before Hanmeet.. so the plan was made to do a mega mission of driving my ute and trailer down, fly back, drive my falcon and trailer down, then flying to Wellington, catch a bus, a train then walk up to his place to pick up a car ive never seen in person and then drive it to the ferry within 1hour... made it without breaking down, must be a record for me in a Hunter.. Got into picton and drove to Blenheim to take it for a wof... I was parked up at some park adjusting the front wheel bearings at 4am, as you do. go through the VTNZ check with a few things... headlight low beam was blown.. balls... cant find anything off the shelf... so I carried on to Hanmer... car drove bloody well.. EVERY time I stopped there was some Barry coming up to me with a story about a Hunter, was getting a bit much when I was filling up with fuel to look out the window and some random sitting behind the wheel pining over their youth... Got to Hanmer, met some OS GC's, good weekend... then the big mission of driving to Invercargill via Wanaka to check out another project.. Car ran so good, but blew a flange gasket which pumped fumes into the cabin.. that sucked.. Got into Wanaka and found it sprung a leak of the slippery stuff...fuck it, carry on son! Made it to Invers and in total she had lost 500ml of the Iraqi gold. List of shit to do for a wof: Headlight - find one from somewhere Rebuild the calipers - large brake inbalance and the remote booster has been removed Apparently there needs some steering box adjustment, although they dont have any adjuster..may have to play round with shims etc... Shit I want to do: Fit the escort rostyles Fit twin carbs Definitely replace all 4 shocks that are FAAAAARKED! when you go around corners the mudflaps drag on the ground, check pics for body roll travel, its lots Weld on a seat adjuster lever so the drivers seat can recline again Paint - maybe? Hope to get it wof'd asap and go for a hoon legally.. So massive thanks to @M Night Shamalayan and his mrs for putting up with the car for so long..1 point

-

It's pizza time again! Yes, we are heading back to the old favourite. They are staying open later especially for us, so dust off your whips and come get some. When: Thursday 20th September, 7pm Where: Wholly Bagels Thorndon - MAP We will be parking in the bottom carpark, entry from Murphy St will be easiest. Bring your hot sauce and your saucy selves. Foam over it HERE1 point

-

1 point

-

There's a graffiti spot near my place, next to the old winter show buildings/current Whitireia school1 point

-

1 point

-

Kinda lame update but first mod so thought Id better post The factory horn was farked so instead of buying a cheap plug and play replacement, used as an opportunity to install these puppies that my dad had been hording in his shed. They are off a 70's Nissan President, and were actually not as easy to install as you might think as pretty huge and wanted to leave a clear path around the rad for future intercooler and piping. In the end found a sweet spot though, whipped up a bracket. Installed (though not yet wired) Honk honk!1 point

-

Just brought wheels bearings yesterday and fork seals today and have no idea when my frame and parts are due back from powdercoating then I can reassemble it . Really wanna get a solid 300k ride in before loading it on the truck for the big trip north1 point

-

Yeah these bikes are so simple and so much fun. Hit up Callum for some shinko 80/90 17. They fit great and handle well and they look good too. about 65 each . Sportier tread pattern too1 point

-

1 point

-

1 point

-

Pro tip: Don't work on your cars when jetlagged. I managed to get the passengers door unlocked but the rod came off the latch mechanism in the process. The drivers door lock is jammed/fucked and I broke the plastic knob trying to get it un locked. Anyone got tips/tricks on getting this fucking thing open? I've tried nothing and am all out of ideas1 point

-

1 point

-

1 point

-

I also came back early from my xmas holidays specifically to work on the patio area, I managed one day on it then it rained for 5 fucken days.. used that time to hang a TV on the wall. Don't have a before shot as usual, well I kind of do.. Wanted to something with a whole lot of free bricks I got, decided on a herringbone style with a border, I ended up doing away with that particular corner style and just did a straight border no square, [/URL Filled it in with sand, out took me almost 6 months to get to this point such was my lack of motivation for paving.. I wasn't sure what I want to fill it in with, had a while lot of hinuera stone paving which is really nice to walk on but only had enough for 16 squares, I needed 24.. then doing a job for a client and he had a huge pile of crushed limestone which when got with a compactor goes pretty hard (fwii).. was sold. My little girl doing her bit, had to be on the rake.. that's her roller you can see in Wellington colours Came up quite a lot better than I had imagined There's also been quite a bit of planting going on as you can see by my partner.. some stuff I'm not so sure about.1 point

-

Pulled the back seat out today, found this Pretty cool to find the build sheet in such good condition1 point

-

Continued with the tedious job of underseal removal, 4hrs in and maybe 1/8th of the job is done. But it’s on the easiest parts to begin with so am expecting that to be faster progress than the other parts again I’m happy with the condition of things under the underseal, better news yet is that most of my parts have arrived from Rockauto and the contents just waiting on the ball joints to turn up now,1 point

-

1 point

-

I drove the car home from work, what a whale, (it’s funny it literally has the world smallest carb, I’m sure it’s about the same size as the one on the 235 blue flame 6 cylinder that’s in the wife’s Belair) this showed a couple of things that will need attention, the fuel and temp gauges don’t work, the power steering box has excessive free play in it but otherwise drove nicely, I showed the wife (so she understand why she won’t be seeing for a few months.....maybe longer) put it in the garage, lifted it up on ramps in the back and axle stands in the front, realised how much flex is in a pillarless car as if I had the axle stands behind the front axle centre line, the doors opened and closed noticeably less nice, can understand why it’s common to put subframe connectors into these vehicles and it’s definitely on the list of things to do after compliance have had a good look under and around the car and have come to conclusion that it really needs to have the under body blasted, it looks to be nice and solid, but there is a fair bit of rust/dirt scale. I’m going to go see a chap in Pukekohe that has been recommended to me to see how much it’s going to hurt to have it done. All the fixed hard hard fuel and brake lines will need to be replaced so I will get them out in the next week or two and get them re made and refitted. The brake line on the diff was obviously made too long so some ones fix for this was to wrap the fixed line around the axle tube, The RR 1/4 has rust starting to come through on the inside and out. Not enough to stop compliance so that will probably wait until afterwards. There is a little bit of rust in the LR spring hanger mount point in the chassis rail but it’s bugger all realistically so I’m happy. The PS box and pump both seem to leak, there is wiring to the gearbox that has been on the exhaust at some point and melted, there is sign of a trans pan leak, obviously the fuel gauge has been an issue as some one has rangi’d and earth wire to the sender unit, And rockauto has given my bank account a hammering tonight, I’ve ordered wheel cylinders, brake hoses, temp sender, pitman arm, idler arm, all inner and outer tie rod ends, engine gasket set, ps box and pump gasket sets, full poly urethane suspension bush kit, all four shocks (uprated KYBs), All upper and lower ball joints, i messed up and ordered 2x suspension bush kits, I’ve cancelled one so I hope that gets caught before the pick and pack it, and they refund me my money. Over all I’m super happy with it, I think it’s got huge amounts of potential and I can’t wait to get it legal and start tidying up the body and personalising it1 point

-

Its running a 318 LA V8, recently rebuilt auto, AC, PS, it does have some rust but it’s an Arizona car so apparently a dry car. Floor pans look good, just general surface rust, Will need all the basics of Vinning: brakes, headlights, suspension bushes etc, rust: Suspension interior Needless to say I’m very excited and can’t wait for it to be delivered so I can work out what I need and start ordering parts from rock auto.1 point

-

1 point

-

Cheers, yeah sure. It’s a Guillows 1/16 kit. I got it off mighty ape.1 point

-

Not sure what bent the rod. Pre ignition and over reving maybe? couple people have said maybe it's hydro locked? it sat for a while and the head gasket was mint, there wasn't any rust or difference in surface, so dont think it was water. someone suggested a cylinder flooded with fuel witch would seem like a reasonable answer?? see how goes, if it runs and lasts a month I'll be pissing my self with laughter. 6months of daily driving, and I'll be speachless and bragging of my hori engine building ways for years to come..1 point

-

This weekends effort.. Didn't really start putting any on till almost lunch time yesterday, was busy trying to clean up plaster dust and wood shavings from the architraves round the windows in the bedrooms. Coz we had to push the windows out 15-20mm I had to put a cunt of a little fillet in between the arcs and the window reveal, did I say it was a cunt.. it was, done now tho. Bit of painting going on inside too..1 point

-

Today is the day when after nearly 3 months on axle stands in the garage, the wheels are back on! Much excite. The painfully slow brake rebuild is finished. The daughters helped me bleed the brakes (they are finally tall enough to push the pedal). Once bleeding was complete I got number 2 daughter to put both feet on the brake pedal and hold it down to check for leaks of which there were 2. I managed to stop the leaks by nipping up some fittings. Actually by doing them up quite a bit more tight than I'm comfortable with... I felt brave enough to drive it to the servo to pump up the tyres. The car looks quite non-derelict so I don't think I'd get pulled over unless I was doing something stupid. The brakes feel really good. Got treated to a wash too!1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.jpeg.e0a4bff61111e0c8c7396950fcc94da1.jpeg)