-

Posts

402 -

Joined

-

Last visited

Everything posted by f100_dreamin

-

Talk about this here

-

Been a while since there has been anything to update on this old girl, the plan had always been to upgrade the 6 cylinder and manual to a V8 and auto for the ease of cruising, it will also provide the opportunity to upgrade to power steering and allow me to run an AC compressor as an air compressor for the Airbags. So just the other day I was able to pick up this from a friend, who had removed it from a customers pick up to replace with a crate 350, apparently it was a good runner when it came in to be replaced (aren’t they all though haha) my mate had planned to take it to a swap meet to sell, but never got round too it, and he ended up just wanting it gone from his workshop, so a deal was done and it’s now sitting in my garage, The numbers break it down to a 2 bolt 283ci (4.6 litre) engine. Nothing flash, but with a freshen up and a little cam it should do the job nicely luckily he also had a bunch of spares to give me too, Including an old school Offenhauser inlet manifold on top of that one of my friends has been stripping a VN V8 station wagon for the engine to put into his VL sedan. so in exchange for doing the wiring and a couple of the shit jobs he doesn’t want to do I now have a 700r4 to go behind the engine. will be a while away until anything gets done from here as the Plymouth is the main priority, but I’ll slowly be collecting bits and pieces for when the time is right!

- 31 replies

-

- 13

-

-

Had a delivery from Rockauto a couple of weeks ago, Diff rebuild kit and Rear wheel bearings for the explorer 8.8, Engine mounts and a new water pump for the 318, Started with the water pump today, which then let me fit all the ancillaries, cleaned up the engine mount brackets and put the new mounts on. I was originally planning on ditching the AC and running a set of gilmours, but I can’t make them work with the PS, and I’m not willing to ditch that for now. So I figured if the PS stays then the AC may as well too! still need to get a new harmonic balancer, and I’m taking the belt pulleys to work to run through the turbowash, I’ll get them cleaned up, painted and mounted so I can work out belt alignments etc.

- 47 replies

-

- 13

-

-

Shit that’s awesome Clint! Nice work!

-

Sweet cheers @cletus, If there’s no one local then I guess that will be the go to,

-

More small jobs have been done , I’ve cut all the old brackets off the diff housing now so I just need to order some spring perches for it now. Has anyone got any suggestions of a local supplier to save me having to source them from the US? I also put my big boy pants on and started cutting the rear 1/4 panels off as marked by my metal guy (so that the inside structure can get blasted too) Before (you can see the lines drawn by my metal guy): after: No more rust than expected, which is good I suppose haha, one side down…..one to go……..

- 47 replies

-

- 16

-

-

Mr.mk1's Mopar or No Car '70 Dodge Coronet

f100_dreamin replied to RUNAMUCK's topic in Project Discussion

Shit that’s an effort and half! Nice work!! -

Took the axle tube to work and cut it down, then when I returned to our Wiri site I used the press to push the axle tube back into the housing luckily it just fit then I welded it back up, I plug welded it where the factory used plugs to hold the tube in, plus I also welded both tubes to the centre as with it being a press fit it’s not unheard of them seeping. Bloody handy having these tools at my disposal at work. I’ll order some spring seats soon and make a jig based on the old diff to weld them on, not a huge amount of progress, but better than nothing.

- 47 replies

-

- 19

-

-

Thread dredge….. aside from scraping more under seal there’s not too much I can do to the body for now, so I’ve been working on the Ford 8.8 I pulled out of an explorer. everything looks good inside, so that’s a plus I wrapped it up to limit the stink, Because there isn’t much that stinks worse than diff oil haha I drilled out the 3 bungs that hold the long axle tube in and took the diff housing to work, with a bit of persuasion from the 10t portapower and the gas plant I pressed the axle tube out, tomorrow I’m going to work at our Drury branch where the engineering department is so I’ll use the drop saw to knock 3” off the axle tube, and then work out how I’ll press it back in so i can weld it up, then I’ll be one short axle and spring seats away from a shortened super strong rear. feel free to discuss here

- 47 replies

-

- 15

-

-

Mr.mk1's Mopar or No Car '70 Dodge Coronet

f100_dreamin replied to RUNAMUCK's topic in Project Discussion

Very cool, looking forwards to watching this build!! -

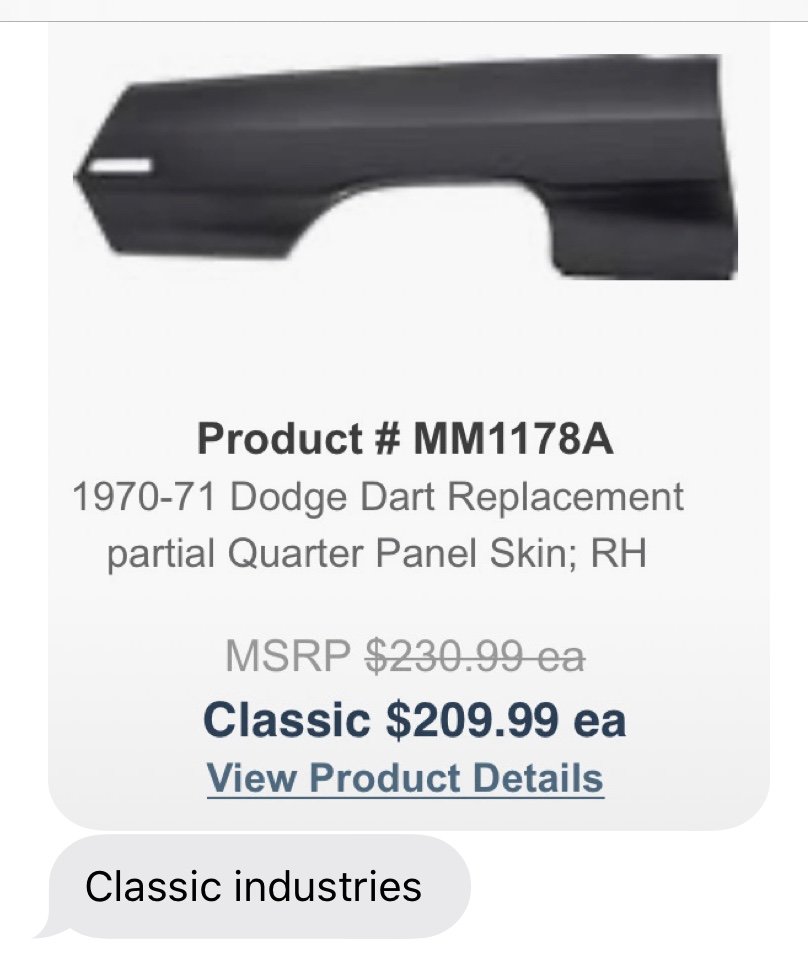

Rear 1/4 panels have arrived, shipping and GST was $950, which is more than I expected, to be fair I had nothing to base my expectations on so not a surprise haha. sat one of the panels on the car, they look good and the lines seem to line up good so I’m happy. the side marker lamp hole at the back of the guard is different because these are technically earlier year Dodge Dart panels, not that it matters as they will be getting filled in anyway,

- 47 replies

-

- 16

-

-

Well rear quarter panels have been ordered and should hopefully be on the way to my shipper in the next week or so. ended up going for Goodmark panels through getallparts.com after a recommendation from an American mopar site I’m on (FABO) so far they have set me back about 790 NZD shipped to my shipper in California, so once he charges me the GST and freight, I think I’ll still be pretty happy with what they cost me.

-

Flogging a dead horse there mate, @Shakotom has forgotten he own the olds I think haha

-

Haha yeah I saw that, and then I saw the price too. Depending on the exchange rate and shipping I shouldn’t be too far off getting two of them to me for similar money (I hope haha)

-

Yeah it’s not what I was expecting, but luckily I’m super happy with how it’s come out. Now a bit of jewellery is done, I guess I’ll have to go back to scraping under seal haha

-

Well with being back in lockdown has provided some time (when I’m on my off shift) so I got the engine almost repainted and assembled new gaskets, frost plugs etc Hoist earning its keep again Messed around with a couple of ideas on the rocker covers settled on engine coloured with black fins Ended up with this, still have to do the other rocker cover to match, just waiting on some more paint, I ended up getting VHT early Chrysler blue, it’s a bit greener than I what I was planning on using, but I’m actually happy as with how it has come out! not a bad use of a day off

- 47 replies

-

- 22

-

-

-

Man that’s some clean sheet metal there Clint!

-

I have my Plymouth insured with classic cover on “project cover” which means it is covered at home in the garage but also during transport to and from workshops.

-

Haha yeah worked a treat though

-

-

Finally managed to get to zebra to get a rear diff from an explorer, I missed out on the one @cletus told me about because I was slack. anyway Zebra finally had one come into stock at the end of June so I went out this morning and plucked it out of this gladly all bolts came out with out a fight and it ended up with this It’s 8.8 inches of Ford goodness, 31 spline axles, factory disc brakes with onboard handbrake, it’s a 3L73 so 3.73 ratio LSD, need to source another short side axle, shorten the long side down 3” and it will be just narrower than the factory mopar and is the same stud pattern as the VJ valiant front brakes I’m using, it’s a well documented thing to do in the USA so there’s an abundance of information about it online.

- 47 replies

-

- 13

-

-

@RUNAMUCK Yeah I have a thread on FABO already (pretty much a copy and paste of this one) will be asking a few questions closer to the time, @piazzanoob the shape of the wheel arches are actually fairly complex, would be more work to fix than replacing the the full 1/4, there is a bunch of bog in places that doesn’t make sense etc, just shit in general haha.

-

@piazzanoob Yeah the budget has long since been forgotten haha, at least once it’s done it will be right. And I imagine it will drive a whole lot better that it did haha, It needs both rear 1/4 panels. They are available from classic industries so just a matter of getting the money together and get them ordered.

-

Haha I’m leaning more to tubbing it than not so will see what happens when I start cutting the 1/4s off

-

Well I picked the car up from R3 Fabrications, well I picked up what’s left of it haha, that’s all the parts that were on the car when I dropped it off, car is all straight and back home so that I can continue to strip under seal off, and start saving, plan will be to buy new rear 1/4s from the states, have it blasted and dropped back to R3 to be put back together so is a sizeably large financial requirement so may be a while away, And now there is an internal fight with myself as to whether I should Or shouldn’t mini tub it while it’s in this state

- 47 replies

-

- 14

-

-