-

Posts

17437 -

Joined

-

Last visited

-

Days Won

134

Everything posted by yoeddynz

-

Bench testing continued. The sump was now holding oil. Phew. I fitted the old smiths mechanical oil pressure gauge that was originally fitted in the imp race car. I mounted the gauge to the temporary coil stand. With the engine cranking over it was seeing about 20 psi. The oil level would drop in the sight glass and after a minute or two it would be back to the old level. I was happy with this. Next on the list was to check the idle control valve was working. Its a 2 wire Bosch style pwm type unit. Very common, simple, reliable and hence used often in megasquirt installs. Its basically a rotary valve that is opened against spring pressure by a solenoid windings when current passes through them. The ecu earths its ground wire in a series of pulses, the quicker the pulses the more it stays 'open'. Simple as I thought.. but.. this is where I discovered that I had bought one of the units that is actually 'closed' at about 30% duty cycle. A failsafe on cars that use these for closed loop idle control (aircon/powersteering/epic sound systems etc etc) If the valve fails then spring pressure actually takes it to a slightly open state so the car cant stall. But I'm only using the valve for open loop at start up. So when its closed I want it to be closed. Luckily I was able to pick out/burn/pick out/burn/pick out the tough as epoxy that was holding the valve stop adjustment screw in place. I wound the screw in until the valve was closed with no power. It still passes a tiny amount of air but its much better. I'll manually adjust the idle bleed screw on the throttle body to get the fully warmed up idle where I want it when that time comes. Which was going to be soon I thought! Next thing to check was that the crank angle trigger wheel VR sensor and the camshaft half moon hall sensor were both putting out satisfactory signals. Opened up the composite logger on tunerstudio expecting to see nice clean signals. But there was nothing. My heart sank. Oh here we go.. I took off the cover on the main board plug and checked the connections there. I then popped the volt meter, set at AC volts, onto pin 1 and 24, wound the engine over and got about 2.0 volts. I don't have an osillioscope and only have an old megastim 2.2 testing unit which won't create the required rpm signals I needed for testing. I wasn't quite sure what to check next so I started a thread on the megasquirt forum. Got some bits of advice but in the end I rang a mate in Richmond who has a lot more knowledge with megasquirts and has helped me out in the past. Organised to go see him the foloowing day. In the meantime I checked the hall sensor. I had never been able to find confirmative details on the polarity of the hall sensor even though it was a really commonly used unit among many a citreon/fiat/renault etc. I finally found a factory service manual online for Fiat ducatos which had a pin out of the sensor. Turns out I'd got my polarity wrong and after swapping the wires around at the hall sensor plug I now had a strong clean cam signal. I also made a mandrel to hold the old honda 12-1 trigger wheel in the lathe. Then I made two jigs. One for the spare goldwing VR sensor, like the one I'd fitted to the engine. The other jig was to hold a Mazda V6 VR crank sensor of which I had a few kicking about and had used them with no issues on the Viva. I spun the trigger wheel up in the lathe at various speeds and took voltage readings of both sensors. The readings were very similar but I still couldn't tell what the actual signals are like. The next morning I drove out to mates place and he set to work on my ECU. He compared the board to his spare Ms3x. looking for any differences. Remember I had bought this ECU secondhand from someone on trademe and was told it was working. I had swap some of the circuitry jumper wires to suit my application. Once he was happy there was nothing major missing on my board he got another spare ecu he had and ran up my sensors in his test bed to confirm they were putting out a good signal. Then we (well - mainly him, I just stood about and learned) systematically went through the VR circuit looking at the signals on his osiloscope. Discovered that transistor U7 was faulty so he kindly swapped out the known good item from his MS1 which I'll find a replacement for him. After that he found a loose, terribly soldered resistor in the circuit- when it was wiggled the signal would appear.... re-soldered that and hey presto - clean signal. Lots of other pins got re-soldered too. The Goldwing pulse generator/VR sensor puts out a much weaker signal that the Mazda crank vr sensor. we double checked them against each other and the Goldwing item struggles at slow speeds (cranking type speeds) so I'll swap over to the Mazda item. When I got home I quickly tried the repaired ecu out and now there's a good rpm signal but it drops out of sync but I took a log anyway. Then started making a new bracket to suit the Mazda sensor. New vr sensor in place and wired up. I then had to remove one cambelt, which is so easy to do on these engines, remove the trigger wheel, file off the old key and weld a new one in place to suit the mazda vr sensor position which was now bolted in the other set of holes Honda used for the original 'pulse generators' as they call them. New trigger wheel key peg.. Finishing that lot got me to this point when trying it out that evening... The red spikes indicate an out of sync situation and no rpm reading but at least the log was clean, consistant and rythmic. Something wrong in the settings, not interference. I tried changing various trigger settings but no luck I was tired so off to bed. Following morning I discovered that when I was changing the trigger settings I didn't spot the prompts to power cycle the engine because I was still on the diagnostics page. So none of those changes took place until the very end when I had actually set it back to the typical default settings. This time a power cycle after changing the capture to falling edge and I got this lovely log... Yay!!! Now I was ready to check the ignition coils and then the base timing. What else could possibly go wrong? Coils all tested fine and the sparks were nice and clean looking. I then marked the timing mark on my custom crank pulley and tested the base timing. I was out by 4 degrees. Pretty happy that I had got my trigger wheel so close. Simply changing the trigger wheel offset value in the settings by 4 degrees had the timing marks line up bang on. Engine start up time was here! I went to bed happy, excited and somewhat nervous about what could happen, or not... So this morning it was time to roll the engine out on the table to the front of the workshop, throw some fuel into the mix and see what happens. I set up the garden hose just in case, taped my phone to a light stand, started recording, tentatively went for a start and this is what happened... Wow!!! Faaaaaaaaaaaarking awesome! What an occasion. What a milestone. Such relief and much giggling with joy. I couldn't believe it. First start on my own custom built engine and it sounds bloody amazing! That was starting on a basic universal base map loaded onto the ecu so I was really expecting a lot more mucking about with the starting settings to get a clean start. I was stoked! I tweaked the cranking settings slightly and now it would start on the button after a few cycles... I can only run it for a few seconds as there is not a drop of coolant in the engine. So my next job is to set up a makeshift coolant circuit using a spare Nissan micra radiator and setup the Davies Craig electric water pump. I can test for leaks and then I can really have a good crack at setting up a nice clean starting and idling tune. I'm so happy! Alex.

- 98 replies

-

- 114

-

-

-

Part 2... catching up now. I finished what I needed to on the loom to enable testing of the injectors. I had made a simple little alloy jig that I could bolt the two rails onto and it sat high enough that 6 matching jam jars could sit below. We set this lot up on the big mobile steel bench and rolled it down to the front of the workshop near the entrance just in case it all goes a bit wrong. Set the ecu up along with a little 'ignition' switch and starter button for later testing of various engine sensors/ test running. The tuning software that megasquirt uses, Tunerstudio, has a good set of testing programs built in including injector testing. Started using that and as soon as the injectors primed and started squirting we found a tiny leak. Poos. My home made rails were brazed together and there was one teeny bit the bronze hadn't flowed into leaving a tiny pin hole that let out a comical jet of fuel. Glad I tested them now. Here under that lovely layer of carefully applied epoxy black... was a tiny hole.. So out with the oxycet and I brazed it up. Then re-tested the setup. No more leaks We ran through a few tests and made notes on fill rates at different opening times/frequencies etc etc to work out the injector dead times. Not a crucial thing to do but since it was setup as such it seemed rude not to. The battery I had was a bit tired and my charger couldn't keep up so I installed a larger wheeled type of Nissan charger at the front of the workshop. This also meant the testing was being done at a realistic voltage you'd expect to see. Happy the injectors were all matched and meeting the factory Nissan specs I packed all the stuff away. Then I fitted the inlet manifold gaskets and bolted the inlet in place on the engine, followed by the rails, with the repaired bit hand painted with epoxy as best I could to match. Next job to finish was the Bosch style idle air control valve. It had far too big in and out bosses so I machine up some stepdown parts to suit a more sensible sized tubing. I needed to mount it somewhere out of the way, safe and not on view because its not very pretty. I spotted a handy bracket on the bottom of the starter motor that has a threaded hole. Perfect! I made a little P clip to suit mounting the iacv. which bolts here.. Like so... I did some more plumbing to suit and after a few last little bits of wiring the engine was about complete. I fitted the pod filter I'd bought a while back directly onto the throttle body but it will actually end up remotely mounted in a cooler spot. I was just waiting on some posh ventilation hose to arrive. The Imp got a fresh wof and we took some pics of it when down at a local swimming spot near Motueka. It looked neat on the river stone so I took some pics.. Went hooning up a local valley to get wild plums.. Got home and snapped some pics of the engine next to car. The perspective makes the engine look huge... Next stage was to bolt the exhaust headers in place properly with the new gaskets and special nuts I'd bought. But before playing with exhausts always be aware of the potential dangers, as so carefully pointed out in the workshop manual !... Manifolds bolted up fine but a few of the nuts are awkward to get started as its tight on space around the header pipes. Next parts in the exhaust chain was the flexible joints. My welding was improved a bit by wearing some reading glasses. I guess I just have to accept that aging thing and embrace the power of +1.5 because now I could actually see what I was welding. Its still not instagram weld porn but it'll do for this project Bolted the cross member in place and with a bit of alloy I was able to check the heights to weld the next sections at. Unfortunately I must have fabricated the LH manifold out of line and I have ended up having to weld the secondary pipe at an angle to make sure the outlet heights match. It wont be easy to spot when its on the car, with a exhaust box hiding them. But I know its there... Or maybe I don't bother with a single large tranversely mounted silencer and just run a couple of old dumpy mufflers... I was now at the point I could fill the engine with oil and test the oil system. Quite a while back I bought some quality oil when on sale.. I filled the filter up first and then carefully filled the engine. Up until this point I had no real idea of exactly how much my resized sump would take before it got to height I wanted it at. I'd done some basic sketches and napkin formula and I knew it would be more than 3 litres. Hopefully more than 4. It almost took 5 litres to get to the halfway point on the sight glass and that will drop once the oil pump primed up and filled the oilways. Cool. Great news then. I'm really happy it'll have a decent amount of oil in there. Now remember back to around the end of December 2021 when I wrote this... "Lastly I needed to bolt the sump cover in place. I had to think carefully about bolt placement for sealing purposes and get the bolts square. This sump plate is going to have to be sealed well because there is no usual high sided sump like most cars. Hence I built it rigid to help against flex. Good quality sealant will be the order of the day* *It will leak. Its a British car. Its destined to leak." Well then. Guess what. It leaked! Ha. Just after patting myself on the back at having a great sump capacity the level started to drop and was leaving a good puddle on the engine stand top. So Hannah helped me move the engine so I could drain the sump and then I mounted the engine/box assembly into the spare imp. On a positive note I was chuffed with how quick and easy it was to bolt up in place by myself - all of about 5 or 10 minutes. Engine in place and with the car up in the air I took that above photo. I had a good idea where it was coming from and wasn't feeling to glum (not even a single toy was lifted from my cot) I unbolted the sump plate and found the hole... Back when I was machining the sump plate and milling the slots it wasn't initially clamped down tight enough and it shifted out of line without me spotting it. By the time I noticed it had moved it was too late. I had to weld up the resulting mess and re-machine that area. I thought it was all fine but I'd obviously missed a tiny pinhole, maybe exposed when I machined the inside of the plate out to take some weight off it. The plate got a good clean (that threebond sealant is tenacious stuff! ) and I fixed the hole with a dollop of JB weld. Took some pics of engine from below with its innards exposed.. Little pistons... Bolted the sump plate back up, waited till the following day and refilled it. This time no puddles. Yay. While the engine was bolted into the spare imp I took the chance to double check measurements and clearances. It was all looking good and I was very happy that I had placed things ideally, especially as most measurements were taken in awkward areas by all sorts of various ruler/tape measure/level balancing acts. The ignition coils for example, just mounted on their makeshift bracket I'd made for bench testing, are actually almost bang on in the right place and only sitting a touch too high. The filter hose will just clear the underside of the parcel shelf and there's heaps of room for the remote filter.. Hose (turned up the day before) .. Hannah's hand holding filter roughly where it will be mounted to the bulkhead... Lots of room out back between engine and where the removable rear valance bolts in place.. and lastly, the 'Mandalorian spaceship' will not at all be hidden by the rear parcel shelf .. Engine is now out and back on the bench for more 'bench testing'...

- 98 replies

-

- 79

-

-

-

Yeah that looks correct.

-

Wow- its been over two months since an update but this project has moved way down the list of what's important to me right now. However I am still working on it where I can because its a nice break from thinking about other things and still really fun to work on plus both Hannah and I really do want to get this engine in. I have accumulated quite a few photos so I think I might split the update into a couple to catch up as its too much to do in one hit. Wiring up the engine management has taken the most time because as usual I got carried away with doing my best to keep the engine loom hidden, the system as standalone from the rest of the cars wiring and make sure its easy to remove or service. I started the wiring off with the injectors but first I had to paint the fuel rails. I chose to paint them in epoxy black for a durable finish. Folding bike stand made for a handy hanging point.. unmasking.. The Nissan March k11 injectors, 3 from the 1.0 litre engine we have spare and 3 from a car at the wreckers. 1.0 and 1.3 k11s share the same sized injectors at circa 145cc/min which is ideal for this engine. Gave them a clean and fitted them in place. I didn't want the injectors to point out to the side as oem fitment in the k11s, so I very carefully shaved off the plastic tab on the injector bodies that locates in the retaining rings. I had to change out the screws for dome headed socket screws, which look much nicer and are stainless anyway, so I could use a ball ended allen key to tighten ones under the now rear facing injectors. Much neater. Bought a variety of this braided loom insulation stuff online. Never used it before. Took me a couple of practices to learn how far it shrinks when slipped over the loom and one has to think several steps ahead to make sure there's no backtracking later. Very satisfying to use though! I'd stripped down a heap of k11 injector plugs and had ordered a bag of the correct terminals, along with a very nice crimping pliers to suit a variety of terminal sizes. However the terminals were not a perfect pressing as per the original items and wouldn't click into the housings securely. So I machined a tiny jig that allowed me to mill out the pressings to suit.. I slowly and carefully wired up the injectors using my new braided sleeving. Such fun! Finished... Now I wanted to work out the electric water pump positioning so I could make sure it was allowed for in the loom build. I popped the imp up onto the hoist, did lots of measuring and scribble drawings.. I had to plan it ahead so the plumbing would be easy to route in to the existing radiator pipes that make their way to the front of the car. Because this flat six is still an unknown thing I really don't want to change anything much that would make it hard to re-fit the Datsun engine (which is still being a very well behaved little gem of an engine!!!) Pump will go about here... Happy with positioning I constructed an alloy mount, taking time to make sure the system is easy to work on, remove and not foul anything else. The pump kit came with an adaptor to fit the temp sensor into but I needed to fit another sensor for the ecu plus the imps water temp sender. The plastic one supplied only had room for the one sensor I rummaged through the alloy tube on the shelf and I cobbled together a suitable adaptor that also suited the hose size I wanted to use. Had to add some alloy flat to give it an area to drill and tap in the correct tapered threads. On the subject of hoses... I spent quite a laughable amount of time trying to find the perfect hose clips. They were all going to be on display and I was quite fussy about the look plus I have a hate for poorly designed clips that don't work smoothly. I don't like clips with the slots as they never work smoothly and tend to bind. I ended up going with JCS high grip stainless items with pressed worm ridges - made in the land of the long grey cloud. British quality! So they'll probably leak then. But they look plus my mate Matt at blacks sorted me out with a great price - which helps because I needed many! I was well sorted for neat little fuel hose clips thanks to many k11s Now back to the wiring loom. I carefully wired up new plugs for the crank VR and cam hall sensors and ran the wires back, hiding them as best I could. Did the same for the alternator and the throttle body tps. At this point I dug the megasquirt 3 ecu out, opened it up and did a fair few alterations to the circuitry to suit my setup. I think it had been setup to suit a Nissan sr20det engine. I added jumpers to allow me to connect the 14 point 7 wideband via CANbus while I was in there. I loaded the latest firmware onto the ecu and it all seems fine (so far) Another trip to my friendly local wreckers was now needed. I took this pic when I parked up.. I was on the hunt for a few little bits including some screw on ends for my spark plugs. I'd bought 6 shiny new NGK plugs to suit the goldwing engine but they, like many bike engines, just have the threaded end with a sparkplug cap to suit. I was changing my ignition leads over to modern silicone suppressed cable I'd bought off a roll along with crimp on car type sparkplug terminals. The screw on bits were not available from my local autosparkies and the prices online were priced at 'absurd plus post'. I found the bits I needed and fitted them.. I continued piecing together the loom and ecu setup. I mounted the ecu on some ply, cut to suit the space under the rear seat. I had a little helper at times.. I decided not to add an extra 26 pin plug into the engine loom to avoid an extra point of potential faults or resistance. I designed the loom to remove from the ecu with the main ecu plugs plus 3 nylon plugs. This way I can easily un-plug them, feed them back through the bulkhead and drop the entire engine out without having to unplug anything at the engine. It also allows me to easily set the engine up for bench testing. The fuses for the engine management, water pump and wideband controller are all located in the same unit, split into two sections separated by the tunnel. To sit in here tucked well out of harms way... end of part one

- 98 replies

-

- 62

-

-

-

Truenotch's 1997 Toyota GranV - Francis Jellybean

yoeddynz replied to Truenotch's topic in Other Projects

Don't forget to make a wooden tray for the dash and fill it with things including seashells, crystals, tiny Buddha figures, half smoked joints, entry tickets from luminate festival 2019 etc etc. Add some prayer flags around the ceiling and you're pretty much sorted for entry into tasman/golden bay.- 32 replies

-

- 11

-

-

-

-

So choice. Excellent choice sir and great that it's not another red/faded to pink. My Imp (and my previous V6 Viva) have a tenuous connection in that they share the same ignition coils.

-

Tiger Tamers 1964 Hillman Minx Project

yoeddynz replied to Tiger Tamer's topic in Project Discussion

For por15/other types of similar paint we punch two holes in the lid. Seal with bluetack (one is a breather) and remove both to pour some paint into a tray etc (or empty hummus pots if your posh like us) The bluetack does need to be swapped/added to once in a while but it's a good system. -

Discuss here about Yoeddynz's little Imp project...

yoeddynz replied to yoeddynz's topic in Project Discussion

Chipping away at it. This project isn't the most important thing in my life right now but it's a nice way to chill out. I'll do an update at some point soon -

I do hope you turned away from the audience, paused for a few seconds and then turned back to face her, cupping your imaginary breasts and with a high pitched feminine tone said "well since you ask and because I'm a laaaaady, I'll now speak for all women"

-

Thousand Dollar Supercar's 1988 Jaguar XJ-S 3.6

yoeddynz replied to Thousand Dollar Supercar's topic in Project Discussion

just to upset the barries at the jag meets - like @Sanfiddy did Plus reliable engine for the rest of your life and with the levels of jag insulation you'd not even hear the mighty LD. But mainly because this is oldschool and its just the done thing. -

Thousand Dollar Supercar's 1988 Jaguar XJ-S 3.6

yoeddynz replied to Thousand Dollar Supercar's topic in Project Discussion

LD28T + manual swap sounds like a grand idea, so leaving some money aside for nats. Get to it now they say! -

Zac's rotary redux project, because he has too much spare time.

yoeddynz replied to ProZac's topic in Other Projects

Extend the living room and move the fd into there. It's clean enough and will create an interesting talking point. -

Zac's rotary redux project, because he has too much spare time.

yoeddynz replied to ProZac's topic in Other Projects

So happy to see some updates with the as usual awesome zac levels of attention to detail. I'm still insanely jealous of your fd - I'd happily have one just to look at and sit in even if I couldn't afford to run it. Hence I'd be going over board to make it nice too. -

Nothing wrong at all with your welding efforts. Good on you for having a go and learning new skills

-

Don't forget the big savings to be had by not using genuine mazda housing seals but instead use appropriate sized electric cable. Not kidding. I've seen it done.

-

Tomble's adorable go cart / distraction / Alto Works

yoeddynz replied to tomble's topic in Other Projects

I didn't really know these were a thing. Very cool. Very dinky. -

I'll just put the old springs back in then. Save a lot of hassle. Then sort the height issues out later on.

-

Yeah that's another idea, although even without knowing the cost of custom springs, i bet they are more expensive then making wire rope retainers (but much cleaner looking....) Currently I have something like 30mm, maybe a bit more, of droop before the straps got tight.

-

Sweeeet. Mine are made from quality strop but I could easily whip up some wire rope items as per above link suggests. @cletus @KKtrips does this sound OK?

-

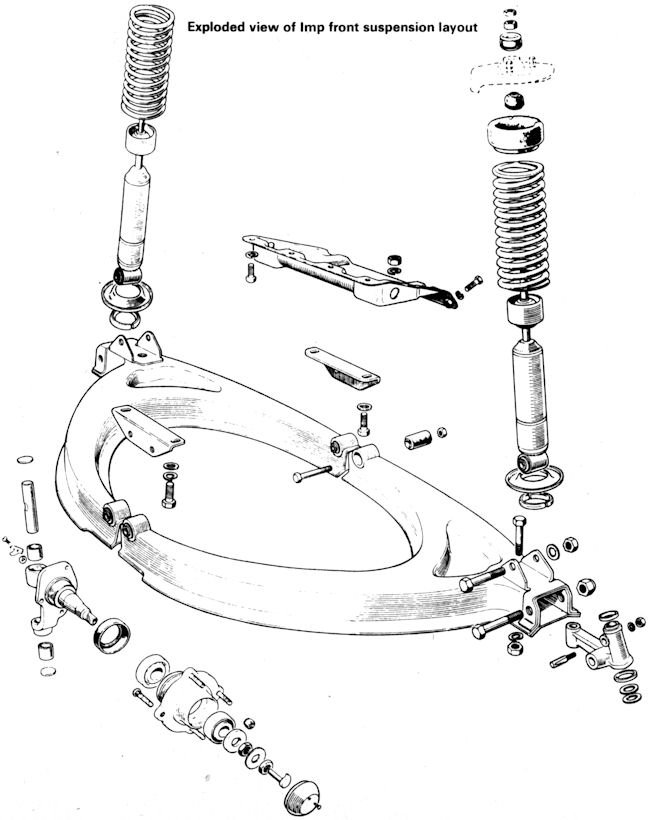

Coil over on the front. Divorced (never actually heard that term used before now) at the back. The back end is fine - the coils there remain captive. Just these loose front springs to sort. I'd love it if I could swap the guts out and put in shorter inserts but I cant as they have non-servicable rolled over ends. If there was enough meat in the wall I'd cut the tops off the dampers, internally thread them and machine up some caps to retain some inserts.

-

Are keeper/helper springs OK for certification? Like these sort of things.. https://www.nzperformance.co.nz/bc-adjustable-suspension-keeper-helper-spring-pa-2 One of the things I'll have to deal with in the future is loose front springs (makita one ways) when the car jacked jacked off the ground. Iirc it's about 20mm gap. Currently the car has some very well secured straps, as is done extensively in the UK with imps wearing shorter springs. But I'm guessing this fix would not pass a cert? So if my 'strap ons' are not good enough then it's some keeper springs or start looking into making some coilovers with shorter insert etc etc but that's a whole new set of questions.

-

Oh - I've not actually watched the first vid. Hmmmm, not sure if I should? It sounds like it could be like stepping straight into the second season of walking dead, or the handmaids tale, having missed the best bits from season one and it generally all goes painfully downhill very quickly from there to the point that you wish they'd just fuck off and finish already, you've smashed the telly in and gone back to the shed.

-

but still very entertaining