Leaderboard

Popular Content

Showing content with the highest reputation on 08/29/15 in all areas

-

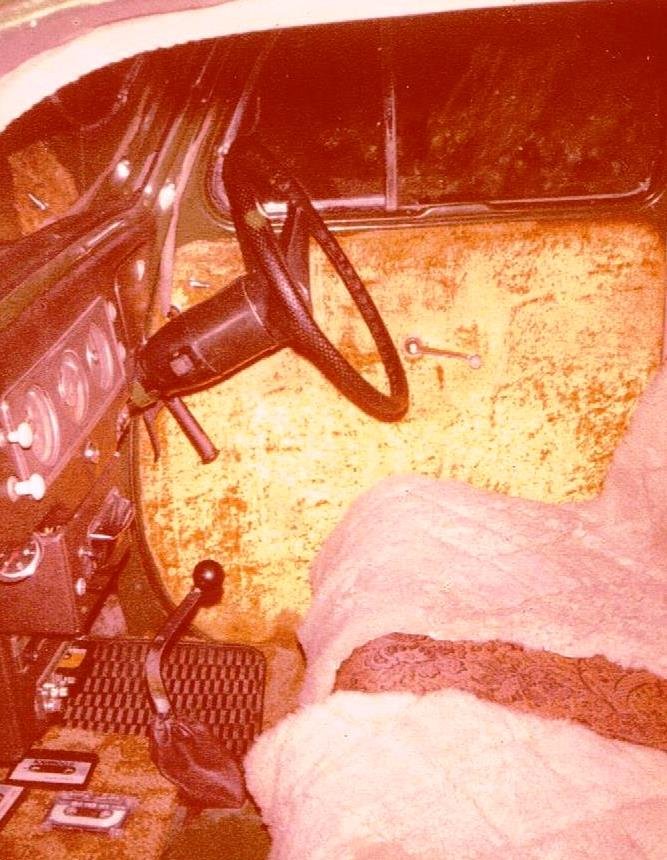

The body was looking a little sad so some panel work was called for and a coat of burgundy paint. Near this time I was ignominiously excommunicated from the Auckland chapter of the Vauxhall Enthusiasts Society for the then unforgivable transgression of “automotive blasphemy”; (i.e. modifying an “already perfect” Vauxhall). Rigamortice loved doing skids with her new motor but the Vanguard diff ratio was far too low and the stud pattern was different to the HQ pattern on the front. When the novelty of doing one wheel burnouts on 15” skinny cross-ply tyres finaly wore off I found a 3.3 HD Holden rear end, fitted it with the larger HQ drum brakes and changed the stud pattern by welding up the old stud holes in the axel flanges and re-drilling them. The old girl was starting lift her skirts and haul arse well (for 30 years ago) and it became obvious the 1930’s style lever action rear shocks were struggling with the additional power and traction so out came the rear end again so I could convert it to telescopic shocks. With a little tweaking of the new suspension I had a car that was happy to be pushed hard and was comfortable with 3 times the original 48 BHP. The only issue was that the standard under floor single circuit 1” master cylinder was having difficulty with the HQ disc/drum combination. I was running a dual Hydrovac booster system with a VH40EL on the front and a VH44D on the rear and despite fitting both boosters with matching “complex” (dual acting) control valves the combination still felt clunky and lacked feel. When late one night I caught myself designing an external control valve system that could operate two boosters simultaneously I knew that drastic action was required and in desperation the following morning, I attacked the driver’s side firewall with an angle grinder…… I mounted an XA Falcon pendant style pedal box and rebuilt the firewall to accommodate an XB Mastervac and dual circuit master cylinder. At the same time I converted to a hydraulic master/slave cylinder clutch combo. Finally the car felt balanced and a joy to drive- problem solved! After a series of small but interesting and exciting fires Rigamortice had to be completely re-wired and I ditched the generator in favour of a ‘modern” alternator. A good mate turned up with a rare (at the time) Yella Terra head he’d procured from his neighbour and it proved to be the ideal combination with the X2 cam, the pacemakers and the DCD Weber (I tried a 350 Holley but it just used more gas and never idled properly). With a little tuning Rigamortice was starting to get a reputation for being a lot quicker than the old tart looked……… love those "one wheeler peelers!"........ One month (and a number of instances of unintended, deliberate, sustained loss of traction) later the Nissan gearbox shat it’s self into shrapnel. I found a W40 Steel case 4 speed Celica box (very sexy in its day) and modified the Holden bell housing to accept it, problem was the main cross member sat where the new gearbox needed to be. I jacked the old girl up, put her on axel stands to keep the chassis straight, pulled the front seats out and cut the whole floor out from the B pillar to the fire wall to expose the chassis. I welded in a piece of 4” RHS to form a new cross member, cut a section out of the original cross member to accommodate the new box and extended the original inside chassis rails. A new floor made from 16 gauge Zintex was welded in and a pair of Triumph 2000 front seats were fitted. Rigamortice had yet another new lease on life.18 points

-

Hi, Just got back from the States. Picked up a C10 Fleetside truck, Custom cab, big window, factory v8 engine, manual. Found it at Pomona swap meet, was one of the more realistic priced car/trucks there. Bought it off some nice Spanish low riders. Pilled heaps of stuff on the back and drove it 100 miles to the next hotel. Got hold of Lucky's towing and had it sent to the shippers to be packed with some other crap and sent back to NZ. Also while there visited a lot of rod shops and car places. Picked up a airbag kit for it, drop spindles and stud conversion. which I'll be installing when it arrives in NZ. Now its just a waiting game. Discuasion Thread11 points

-

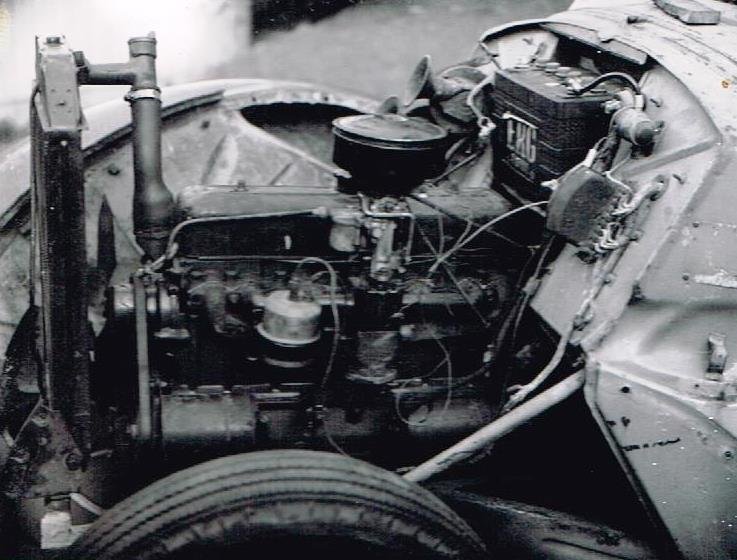

In the summer 1986 I removed all the front bodywork and scrapped the engine, box and front end. I was left with 2 chassis rails and a big hole with a head in it! Soon I was crawling under cars in public carparks with a tape measure and haunting the local car wreckers in search of a suitable front end. I finally settled on a HR Holden wishbone setup that I fitted with reversed HQ stubs and discs. A shortened Austin Kimberly R&P was mounted behind the cross member and connected to a Triumph 2000 steering column. All I needed was a motor and box….. Sometimes you just get lucky, a guy I worked with had a mate with an X2 186 motor hooked up to a Datsun 4 speed and he needed money. $60 later I was poking it into the old girls engine bay. After a few weeks spent fabricating mounts, throttle and clutch linkages, a drive-shaft, etc. Rigamortice’s new donk was starting to look like it was where it belonged. I ditched the X2 twin carb setup in favor of a downdraft DCD Weber and scraped together enough money to buy a set of pacemaker headers.7 points

-

Today we received some really good news and bits! Firstly I got the bonnet chrome installed! Although small really complements the car and makes it complete. I also recieved the WarP 9 motors, Tyco EVC500 contactors and maintenance switch which will be off to the engineer next week to get installed! We also meet with our biggest sponsor Peter, the CEO of ETCO who has opened big oppurtunities for the KEV70!6 points

-

Go tthe mrs to give me ahand to crank this over today, I got her to write down the compression tests (before it started) Not so good on 3 and 4! However ITS ALIVE! https://youtu.be/HCPhc2MetpI https://youtu.be/HCPhc2MetpI Mrs actually got it going first, shes stoked, lol, this my my first start. fresh fuel including filling the carb bowl got it running so guess the fuel pump is borked or has an air lock I forget to test the compression again afterwards but it started & revved well enough so im guessing it was a gummed up valve or something. Stocked as that mean i can get it built up with the existing running gear. Wont be going too far before the engine comes out, for a freshen up but at least it can theoertically move itself around till then! Once it has brakes and a working clutch...4 points

-

4 points

-

FAIL So Hellux failed, but not by much! Have a small list of fairly minor things to sort, which shouldn't take long, and more importantly should cost stuff all. So the seat belt buckles were bolted to the seats, which meant a whole bunch of extra rules applied around the mounting of the seat, so I thought I would just simply bolt the buckles to the factory mounting points on the body. WRONG. Turns out it has no holes/nuts, had a bench seat it did, which seemed odd for an SR5, but guess it was an option or some shiz. So I made up another set of doubler plates for the belts, as seen below, WRONG. The eagle eyed of you, will notice that I welded std M12 nuts to them, they have to be metric fine. Bugger. So I need to change these. Thankfully I got the seat ones rite, so they are all gravy. He also wasn't happy with the floppy material buckle storks, so I have to change them to cable ones. It has to have an engine check light, which I think is slightly odd? Needs a fan shroud, which makes sense. Have to slightly change the front drive shaft loop, easy. And then I just have to take pics of all the doubler plates and hoop mounts that are under the carpet/seats inside the vehicle, and its done. And here's a pic of the old girl in all her hideous glory, ready to set sail for a fail. Grott. Regards, VG.4 points

-

^ depends how much boost you are going to wind into it. around 10psi should be fine on 10:1 running on 98 pump gas. my stinky 4age done 10psi with 11.5:13 points

-

My name's Simon and In hindsight I should have labelled this thread "sometimes you just get lucky". 1973 in little old NZ was a good year. Colour telly had finally arrived (not that any of us could afford one), Pink Floyd released Dark Side of the Moon, petrol was 10 cents a litre, and I was 15 years old and needed my first car real bad! I spotted an old 47 6 cyl Vauxhall parked up in Hastings rd. Mirangi Bay with a faded 4 Sale sign in the window and grass growing through the wheels. After a round of fierce negotiation with the owner the paltry sum of $15 was settled on. With only $10 to my name I borrowed the remaining $5 from my long suffering father, (not sure if I ever repaid him) and the deal was done. After a triumphant arrival at home in my “new car “on the end of a towrope behind Dad’s 6/99 Worsley we discovered the motor was seized rock solid, within days the family was calling the car “Rigamortice” and the name just stuck. The only three early pictures I have was one taken by my mother (thanks mum) while I was bolting the bodywork back in place after Dad helped me with a “rings ‘n bearing” job - all done with the engine block still in place,….. ……and a second of my little sister and my eldest sisters’ daughter (big family) posing proudly beside Simons “new” car. …..and a third from when I found another J14 Vauxhall to park beside (Rigamortice is the green one). Within a few years the old girl had had been fitted with an LIP motor & box complete with Impala shifter, the “knee action” front suspension had been ditched in favor of EIP wishbones, I’d fitted a Vanguard diff and the interior looked like either a cheap massage parlor or Bishop Brian Tamaki’s living room, (the 70’s were a little weird!). Discussion Thread //oldschool.co.nz/index.php?/topic/49843-sr2%E2%80%99s-1947-vauxhall-%E2%80%9Crigamortice%E2%80%9D-discussion-thread/2 points

-

Installed some adjustable arms in the rear and camber plates in the front. Had to make some custom top plates for the front, since the stud spacing wasn't correct. Which was weird since they were meant to fit AE101's. The stance is much better now, looks awesome from behind. Spent the most in one go on this car a few days ago. Hopefully the stuff arrives next week.2 points

-

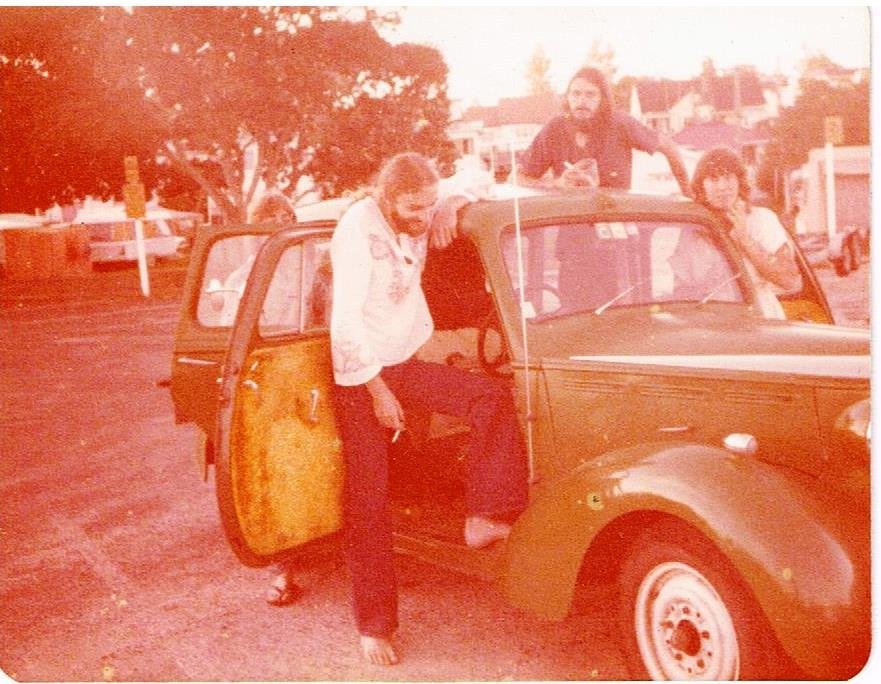

A decade passed and Rigamortice was still going strong as my daily driver. She’d been parked up for a few years while I lived in Australia, she’d been driven by all and sundry, stolen twice and even hauled Band gear around both islands (with the back seat removed) while I was starting my music career. What can I say; my friends and I grew up in that car. Jump forward to the mid 80’s ; the old girl’s still running strong but I’m over being passed on hills and the bump steer is getting hard to ignore; (the future Mrs sr2 spun out in Milford’s main drag while attempting an emergency manoeuvre, guess who’s fault it was!). The time had come for lots more power, good handling and more importantly brakes! (Get a load of the posers in the 1st 2 pic’s, oh the follies of youth).2 points

-

Another six years passed quickly. My beautiful long suffering Sharon, (these days Mrs sr2) and I bought the flat we were renting in Milford, (many thanks to Peter Thomas, RIP mate). My music career was going strong, we were all getting into dirt bikes and Rigamortice was still hauling arse as my daily driver. What can I say, life was good. To be honest she was starting to look a little scruffy, (my early teenage attempts at panel repair were biting me in the arse badly), the little X2 rattled a bit on startup but she still as always did her best for me and pulled strong. Even old cars need a little hug now and then….. In 1992 a collection of overly enthusiastic volunteers from various assorted hot-rod and car clubs formed a committee and came to the conclusion that despite having travelled safely for over half a million miles in various states of mechanical modification Rigamortice posed a real and present danger to the voting public and needed to be subjected to things called “regulations and certification”. I didn’t have a clue what they were talking about but “rules and certifications” sounded very important so Rigamortice and I humoured them by trying to look interested. To their credit they were obviously very clever & determined people who had far too much time on their hands and knew heaps about politics, using impressively long words, inventing regulations and certifications and forming committees to invent even more regulations and certifications! Both Rigamortice and I were overawed by their self-sacrificing tenacity and their astonishingly concise use of mind numbingly self-contradictory terminology - in desperation and under increasing duress we consented to filling out a “Vehicle Modification Declaration” form. At this stage we couldn’t help but be reminded of Officer Opie from Allices Restaurant; (listen from 6:30 to 7:40 or just sit back and relive the full 18 minutes of beautifully, innocent, delicious anarchy). We soon discovered that the “sad little man that the very clever hot-rod and car club committee members had given the task of confirming the above modifications” was in denial that Rigamortice was in fact fitted with a “Starship Enterprise Warp Factor V Hyper Drive” and was not happy with the “structural modifications prior to 1991” being described as “oxidization”. After a vigorous negotiation process where I hid behind Rigamortice while the “sad little man that the very clever hot-rod and car club committee members had given the task of confirming the above modifications” hurled a multitude of thinly vieled insults at me about my car and the marital status of my parent at the time of my birth, we eventually (with a small amount of violence on my part) reached a compromise and I was given paperwork! Eight months or so later a rather confused lady in a L300 courier van T boned Rigamortice very, very hard. Luckily although written off the van hit with the left front and when extracted from the wreckage the hysterical and bruised lady van driver was essentially unhurt. Sometimes you just get lucky.... Modern cars have an effective crumple zone; designed in 1935 Rigamortice just took it on the chin like an old boxer. I drove home in a daze with a very sore neck and a bleeding thick lip while Rigamortice sported a wobbly rear wheel and a rear chassis/sub-frame that had been seriously pushed sideways. A short time later Sharon and I had a baby on the way, we'd bought the house next door and Rigamortice ended up parked in the back yard……1 point

-

They're aluminium. Aluminium is solid until a billionth of a second where it's soft then it's liquid. Hahaha. Feck! Diesel pistons will be forged steel real soon just you wait1 point

-

What about heating the part you need to flatten with a torch? It will slump inward and retain thickness. This is very risky however, for obvious reasons.1 point

-

Finished these ^ on Monday. Accidentally made an extra because I forgot I did one the other day, and found one in the boot when I went to install the one I finished. Also made a new parcel tray with some fancy puffy foam and vinyl to match the seats, which replaces the bodge job I did a few years back, and because I pulled out the LPG tank, the speakers can now sit down lower, although they still require some spacing, with the puffy foam, and one spacer visible it looks rather pro. And then I got carried away and pulled out all the seats and carpet to clean it properly and allay my fears that a leak it had previously might've caused rust. it hasn't. Sweeeeeet relief. But now I'm gonna sound deaden and new carpet it. And wire an amp into the boot. My head deck doesn't have RCA outs but I can just jack the rear outs into an amp can't I? Will find out I guess. Then feed the rear speakers extra lots. The sub install in the Galaxie is underwhelming so CBF putting one into this one. Plus plan is to use this often, so bootspace is handy. I got a quote on blasting and spraying underneath, but when I was pulling the seats out I realised how close to finished I was when I wirebrushed and hand painted it years ago so I should just save the money and put in some hard work. Fuck I hate hard work. But that'll be the plan.1 point

-

Picture-less update. Managed to get the imbalance down to 23% (has to be 19% to pass). After further investigation one of the Pistons had siezed in place , meaning the rear shoe wasn't getting much done. Back to Stirling Clutch & Brake on Monday it is. Hopefully the new part bring the imbalance right down.1 point

-

Would like to think so Brock, got a couple other things on my plate but the intention is definitely there. Car is only a 5-10min drive from yours currently. Should be able to fire it up within the next few weeks - Off to LA for 9 days so that'll slow me down.1 point

-

1 point

-

Had a fellow OSGC drop in this morning so an early morning effort for a trial run before putting it all back together..an epic fail Motor bearings which were about the only thing I hadn't replaced and they decided it was time to seize solid (top one in the pic), managed to fly through the door 10 minutes before Saeco bearings closed, awesome that they had them in stock. Runs a lot smoother and quieter now.1 point

-

Just checked and everything currently has wof/reg. Except for the things that don't.1 point

-

1 point

-

Turns out this particular cert men agree'd that they should be disabled due to them being cunts in general, and that they don't function correctly on a lowered ute, so in my case, it was allll good that it had been removed.1 point

-

If you remove the dome it WILL reduce the thickness of the crown of the pistion making it more prone to overheating in the middle. The reduced skirt will only cause problems with a OEM pistion unless you are very carefull, even stock you see cracked skirts from time to time and they will need to be adjusted for weight once machined. I would also think under piston cooling is a great idea. It really sounds like a set of Forged pistons is what you need, mods to a OEM piston are only going to reduce thier life span further.1 point

-

I roll up all the time without wof or reg becuase I forget when they run out.1 point

-

1 point

-

1 point

-

Keep oil squirters no doubt! That is all. What about heat treatments to increase piston strength? There are coatings that can be applied to reduce heat sink. Gaz1 point

-

Since I'm still missing some front panels it tends to shake around a bit. Aced a few sealed beams in the time it's been alive. I was out a low and a hi when I got the Wof so he gave me the benefit of the doubt knowing I had a pile at work. So I converted to semi sealed dealies. I decided to cut costs, I'd do hibeams in semi and re-use the sealed. Then discovered the semis are a flat glass, mine were curved. So I used semis. Then a hi and an opposing low wouldn't locate into the buckets. So I delved into the parts box and found another 5 to choose from, wit associate chrome rings to suit as it all are the same... managed to sort it but running out of daylight. And one light had to sit 90 degree clocked to actually locate because the bucket was for the other side and I don't have time to mod it with hanmer cruise tomorrow. Adjusted them quickly against door and reassembled. Much more light so far. Also took my OLD pcv valve from catch can pipe and replaced with one from brake booster, and put a new one into fresh booster. Noticed the car was smoking a bit and hadn't before I did the initial swap around. Backed the brake pedal off too, as it seemed slower than usual (haha!) but more so between gears and I noticed the rotors were hotter than should be. Here's a dumb picture from stock so I don't get flack for picture less updates!1 point

-

1 point

-

1 point

-

To give you a small idea, the front and rear bumpers, siderails I did in one weekend. Calculated to over 50m. I swear the welding torch felt like it weighed 20kg by the end of it. Went from doing 2m beads of weld to 2" before it was tiring on the sunday at the end of the day lol! I think Im roughly into the 3rd Spool of Wire now (we have been doing other jobs as well in saying that though)1 point

-

Lack of updates i know busy in the shed and about to go on holiday great timming before race season. tbh im usless at updating but so far from where ive left off we have made new calipers and hubs using a wilwood 6pot caliper and ap racing f5000 front rotors with endless pads which should stop the car1 point

-

Turns out the reason I couldn't get the shoes compressed was that I had a spring flipped and it was fouling on a nut. Mph lack of experience with drum brake shows. Flipped it around, put everything back together and the tried to bleed all the air out of the replacement cylinder. All was going well until this happened The back of the cylinder sheared off completely. Always a risk with 40 year old bits. I've decided to buy a new one. Hoping to get one asap. ZebraDude recommended Strong Brothers on the shore. Anyone know what time they open on Monday? Or anywhere else I can get a replacement cylinder?! I'd love to get one on Monday or Tuesday if possible.1 point

-

After seeing a post from SOHC earlier I was really keen to find some photos of the car in its original ownership by my Great-Grandparents. I've just been slowly working away at the interior. The dash is now bolted in. Just need to install the gauges and reconnect the choke cable. On Saturday I'll have a go at replacing the hand brake cables (front and rear). Hoping to then get a WOF and then come along to the Auckland meet on the 26th. A couple of photos from the late 70's when the car was in Wellington.1 point

-

1 point

-

I've sourced a replacement sorround for the gauges as the one in this car is blistering a bit. The one from the donor car was a few years older and had a different brake warning light. May sound over the top but changing the style of light wasn't an option as that's not original for this car. Have also ordered a new Uni-Joint for the propshaft as I've got all the symptoms of a worn UJ. Banging and thudding etc.1 point

-

1 point

-

So I did some shit on this today, mainly in the boot. I took out the LPG tank a while back leaving a heap of holes and space. So I reinstated one of the bits of steel and used it to build a ply platform that'll hold a sub, because I may as well. Keen on advice on what to do in regards the back of the back seat - it looks like shit. Can I put a bit of mdf in there to tidy it up or is that goning to just rattle and make the sub less effective? Can I vinyl/carpet it? I also made a template for the boot inner sides, just to tidy it up. It looks rough, but it fits near perfect, so when i make the final one I'll worry about getting it all clean and tidy. Adjusted the idle, removed some dead rivets and whatnot from the lpg system underneath. began rebuilding the shit parcel tray speaker set up I made years ago. Pretty good day in the shed.1 point

-

1 point

-

1 point

-

Yeh, I can imagine the BOV venting measured air to atmosphere would cause it to run pretty rich. I'm under no illusion that its going to be shit on gas, but hey, gotta pay the cost to be the try hard mid lyfe crisis flat peaker guy.1 point

-

So, everything is out of my donor car except the diff, rear discs, rear hubs etc. Will have that squared away sometime next week. Motor and trans have been steam cleaned and wire wheeled and is now ready for a re gasket and paint. Will take the rear diff assembly and the K frame complete with power steering rack, front discs etc to work to get them steam cleaned. Will drop a few bits and bobs inc front and rear disc callipers into the Paragon bath.......then boom POR15 time. Have brought new low King springs, water pump and thermostat housing, Holley 350cfm carb, free flow manifold, trans service kit and engine mounts, so once all my shit is clean.......it will be swap time, cant wait!! Oh and I just picked these up today. Brought them from a funeral home. They had been on one of their hearses but they decided to "upgrade". It's pretty cool to know that people are dying to go for a ride on these rims.......Ba dom chhh! Once all this is on, it will be time to tweak the cosmetics. Will fit the rear fender and tail light extensions as well as the tacho from my donor car. Then i think i will stop there and see if I want to proceede any further. Will most likely leave it there....1 point

-

Pictureless update 1) GOOD- I got the heater going again 2) BAD Missus was sqwaking about something, Felixx Jnr was in car yakking away. I was backing down the drive and door was not closed properly. I caught it in the fence paling, ripped 2 palings off the fence and buckled the door skin by the handle Im slutted, got 99% of it out will do the rest when Im clam. Oh I scuffed by new doc boots kicking shit around the yard1 point

This leaderboard is set to Auckland/GMT+12:00

.thumb.png.b2aee08688778d18bdc7b3e3c1852d9c.png)

.thumb.jpeg.384ff72c8d2b0ee0d34a7bdedb55bdcf.jpeg)